What Is a Band Saw Machine?

A band saw machine (band saw) is a machine used to cut plate or cylindrical components, such as wood or metal.

The band-shaped blade rotates at high-speed to perform the cutting operation. It is also called a band saw. The characteristic feature of a band saw machine is that the blades are band-shaped and looped.

The blade, which rotates at high speed inside, is partially exposed and can cut efficiently by moving the blade or material while applying it to the material. On the other hand, compared to the reciprocating circular sawing machine, the band sawing machine is attractive because of its high chip evacuation performance.

Band saws are particularly suitable for cutting thick materials and for cutting at high speeds. In addition, unlike the thread sawing machine with a straight blade, the band sawing machine is faster in cutting speed, which is expected to improve work efficiency.

Uses of Band Saw Machines

Uses of band saw machines, mainly cutting plates, bars, and pipes of wood and plastic. Depending on the model, they can also be used to cut metal components and food products.

Vertical band saws are generally used for cutting boards. Cutting is performed by moving the plate side, which allows for efficient operation. On the other hand, horizontal band sawing machines are suitable for cutting bars and pipes, where the horizontally positioned blade is pushed against a fixed member.

Portable band saw machines that can be recharged are ideal for situations where a power source is not available at the work site or where the material needs to be fixed for cutting. It enables cutting work in a variety of locations and broadens the range of work.

Because of their versatile uses, band saws are widely used in the manufacturing and construction industries. By selecting the appropriate model and type, efficient and accurate cutting operations can be realized.

Principle of Band Saw Machines

Band saw machines are tools for cutting wood, metal, plastic, and other materials. The band saw blade is rotated at a high speed to cut the material efficiently.

The blade of a band saw is a wide strip of metal with teeth cut into it, which forms a ring. The wheeled blade rests on two wheels inside the machine and is driven by a motor that rotates it at high speed. To perform a cutting operation, the material is placed on a table and the part to be cut is pressed against the exposed blade. As the blade rotates, friction is created on the material, allowing it to be cut.

The principle of the band saw machine offers the advantages of higher chip evacuation performance and faster cutting speeds compared to the thread saw machine. In addition, the band saw blade does not move back and forth like a circular saw blade, resulting in less vibration and more stable cutting. An additional advantage is that it can cut complex shapes, including curves and straight lines.

Types of Band Saws

There are three main types of band saw machines: vertical band saw machines, horizontal band saw machines, and portable band saw machines. Understanding the different types of band saw machines and selecting the appropriate model for your application will ensure efficient and accurate cutting operations.

1. Vertical Band Saw

Vertical band saws are generally used for cutting wood and plastic boards. Vertical band sawing machines are capable of cutting by rotating an upright blade at high speed and moving the cut material across the table. They are often used in furniture making and woodworking because they can easily cut curved and straight lines.

2. Horizontal Band Saw

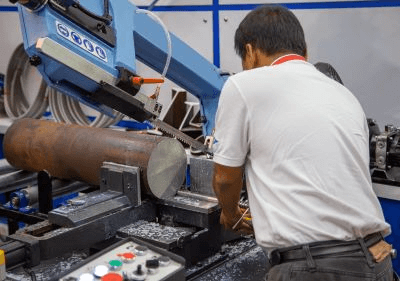

Horizontal band saws are mainly suitable for cutting metal and plastic bars and pipes. The material to be cut is held in place, and the horizontally positioned blade is pressed against it to perform the cut. This type is useful in metalworking, machining, and other workplaces.

3. Portable Band Saw

The portable band saw is a rechargeable band sawing machine that can be used where a power source is not available or where mobility is required. Its small size and light weight make it easy to carry and very convenient for on-site work. It can be used in a variety of situations, including construction sites and outdoor work.