What Is a Rust-Proof Sheet?

Figure 1. Image of anti-corrosion sheet

A rust-proof sheet is a sheet used to prevent rust on objects such as metals. It is also called rust-proof paper.

Rust-proof sheets are manufactured by impregnating or applying a chemical that has rust-proofing properties to a material such as paper. By simply wrapping a metal or other product that you want to prevent from rusting with a rust-proof sheet, you can easily protect the object from rusting. Since it is in sheet form, it can be freely transformed according to the size and shape of the object, and can easily be used for everything from simple packaging to sealed packing.

Uses of Rust-Proof Sheets

Rust-proof sheets are used to protect and preserve objects from rust for a long period, such as in rust-prone materials or in environments where rust is likely to occur. They are used in industries that handle metals such as steel and automobiles, where rust can cause quality problems.

To prevent rusting of products of various sizes, there is a wide range of products that can be used for small parts to large steel products. Although there are variations from product to product, the rust-preventing effect can be expected to last approximately six months to one year. However, it is recommended to use the product as soon as possible after purchase, as the rust-preventive ingredients vaporize and lose their effectiveness even if the product is not used.

Principle of Rust-Proof Sheets

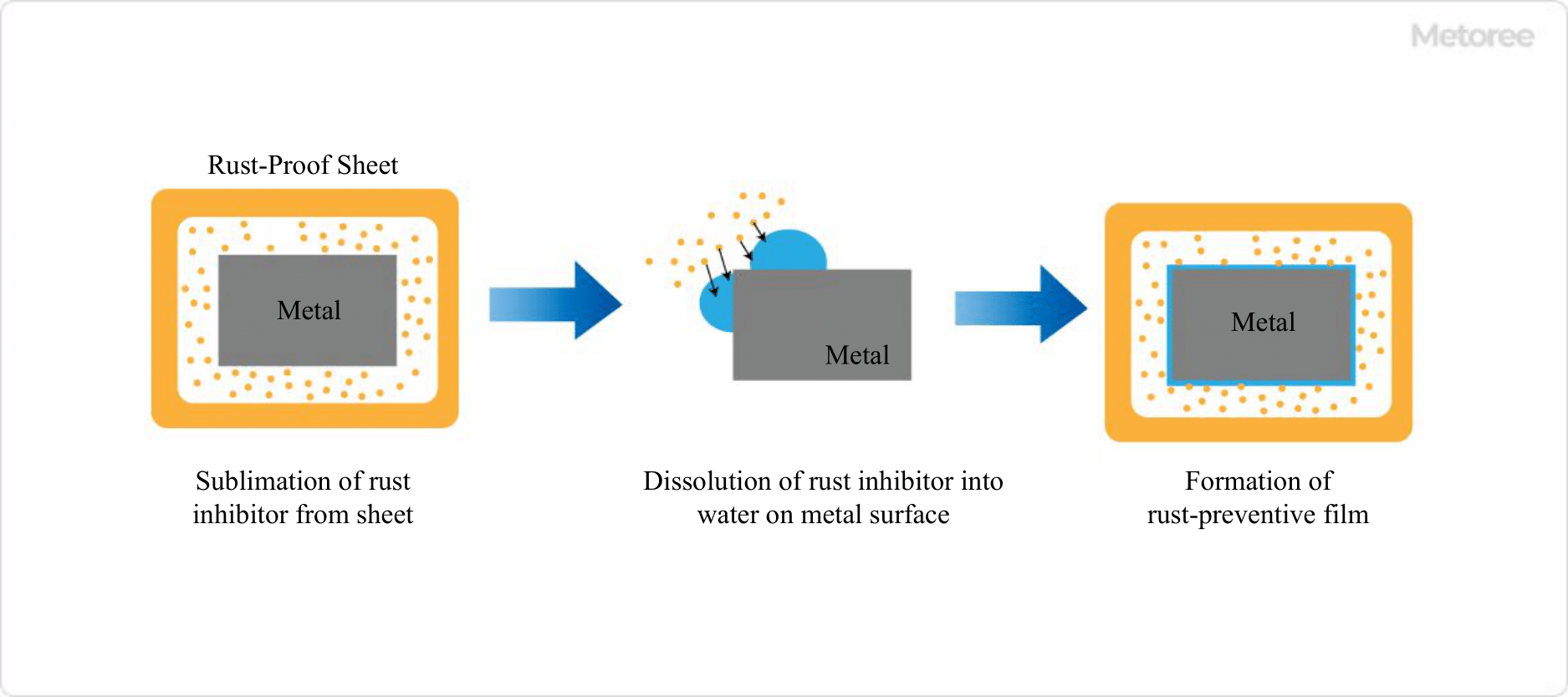

Figure 2. Anti-rust sheet principle

Rust-proof sheets are manufactured by coating or impregnating the base paper with rust-proof paint. Products requiring special moisture resistance are laminated with polyethylene using a laminator.

The principle of how rust-proof sheets prevent metal from rusting is as follows.

The rust-proof sheet contains a rust-proof agent that gradually vaporizes (sublimates) at room temperature, and the vapor quickly fills the sealed space between the sheet and the metal.

The vaporized rust inhibitor dissolves in the moisture on the metal surface. The dissolved rust inhibitor is physically and chemically adsorbed as molecules or ions to form a “rust inhibiting film.”

The rust-preventive film shields the steel from the outside air, which causes rust, and prevents it from changing into rust.

This rust-preventive film made of vaporizable rust-preventive agent is extremely thin and has weak adsorption power, so it does not cause any change in the external appearance of the metal surface. After rust-preventive packaging, metal products can be used immediately without cleaning the surface. In addition, because it is a rust inhibitor that utilizes vaporization, it is expected to have an immediate effect.

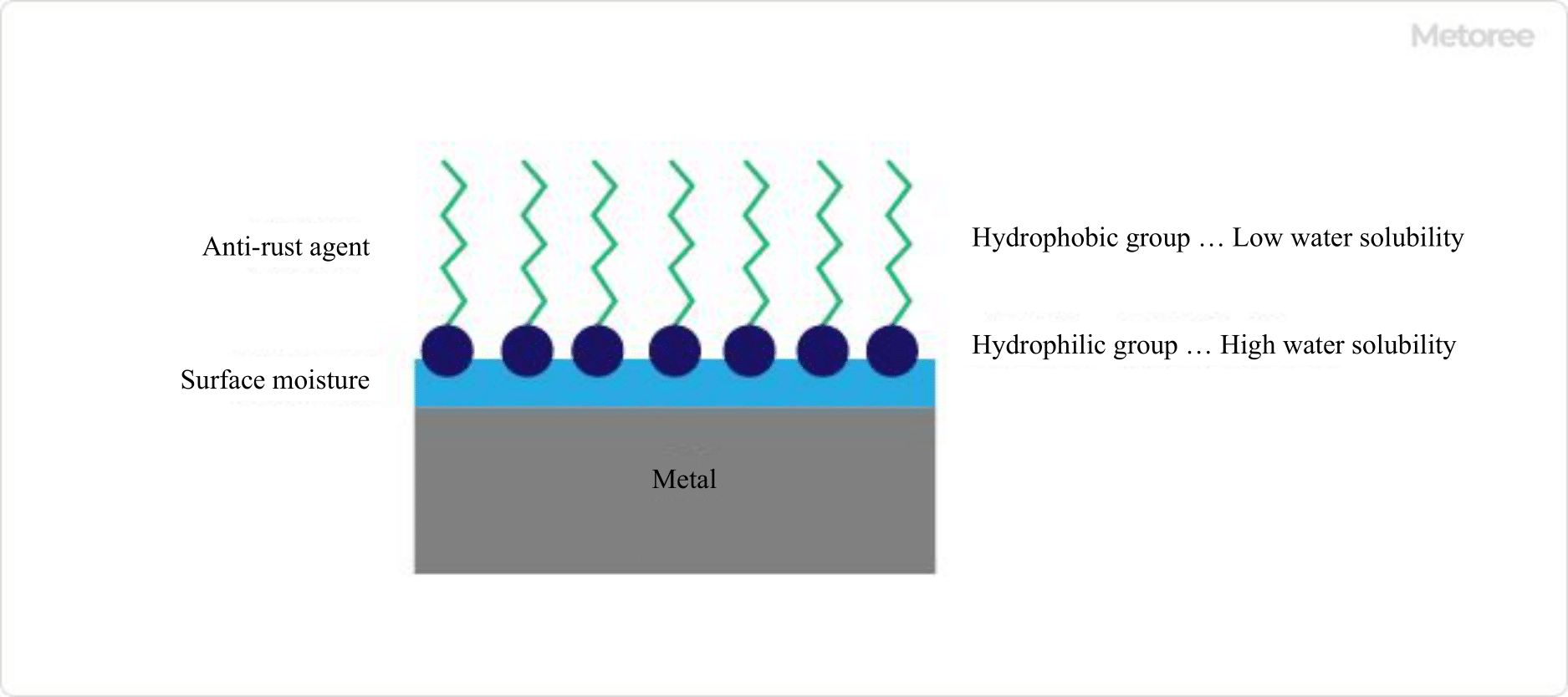

Figure 3. Adsorption mechanism of rust inhibitors on metal surfaces

An important condition for rust-proof sheets is that they do not contain active substances or other substances that can cause rust to form. Therefore, the sheets must also be made of materials that do not contain chlorine ions or acids that can cause rusting.

How to Select Rust-Proof Sheets

Rust-proof sheets are available in a variety of types, including those for ferrous and non-ferrous metals, zinc and iron, and copper and copper alloys, as well as those for iron and steel, which are labeled “for iron and steel.” They also vary in thickness, width, length, and other dimensions, depending on the product. Select a product that matches the type and size of the metal product you want to use.

The coated type has been used in many products for many years, but because it is manufactured by coating the surface of paper with an anti-corrosion agent, the rust inhibitor may adhere to the product when unpacking. The impregnated type, on the other hand, has the rust inhibitor soaked into the paper, eliminating such concerns. Currently, the impregnation type is often used unless there is a special reason.

If higher corrosion protection is required, polyethylene laminate products are effective. They are effective in preventing the inflow of water and moisture from the outside and the outflow of vaporized rust-preventive components to the outside.

Some manufacturers may also disclose the results of discoloration tests on plastic and rubber. If the product you want to prevent rusting has plastic parts, it is safe to check before purchasing. Some manufacturers provide samples for testing, so if you are concerned, you may want to take advantage of this.