What Is a Rotary Bar?

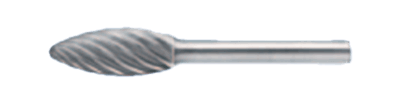

A rotary bar is the tip tool used when using a micro grinder.

It is used for cutting steel and other materials, chamfering, deburring, and shaping the cutting surface. It is highly versatile, capable of processing such as gentle curves. Because of its small size and fine machining capability, this tool is widely used in fields that require precise machining down to the smallest detail, such as in the manufacture of precision instruments and electronic components. It is also used as an easy-to-use tool among DIY and craft enthusiasts.

Uses of Rotary Bars

Rotary bars are used to cut general workpieces, nonferrous metals such as aluminum, brass, magnesium, and plastics, resins, and difficult-to-cut materials such as stainless steel, nickel, chromium, and titanium.

In particular, with the use of specialized blades, rotary bars can cut difficult-to-cut materials such as carbon fiber reinforced plastics (CFRP). They are also used for cutting with hand tools and robots.

Specific examples include cutting in the manufacturing process of automotive and aircraft parts. They are also used by DIY and craft enthusiasts when cutting or machining of small parts is required, and by selecting the blade shape to suit the uses of the application, a wide variety of machining is possible.

Rotary bars are indispensable tools in situations where precision cutting is required. By selecting a blade that is appropriate for the material and shape of the workpiece, an accurate and beautiful finish can be achieved.

Principle of Rotary Bars

A rotary bar removes material by applying cutting force to the workpiece through contact of a blade attached to a rotating bar.

There are several types of rotary bars, including cross cut, spiral cut, aluminum cut, and MC cut, and the blade type must be selected according to the uses of the bar.

The cross cut has low cutting resistance and minimizes mechanical vibration, enabling cutting of hard materials such as carbon steel and stainless steel. Spiral cuts help shorten cutting time because of their high cutting volume, and they eject needle chips. The aluminum cut has a blade shape that prevents welding of work pieces and is suitable for cutting aluminum and magnesium alloys. The MC-CUT has a small number of blades and is capable of rough machining.

Rotary bars also have specialized diamond-cut and other blade types, which are used for cutting difficult-to-cut materials such as carbon fiber-reinforced plastics. They are also used for cutting by hand tools and robots, and are widely used in various fields. By selecting the appropriate type for the cutting shape and material, more efficient and accurate cutting can be achieved.

Types of Rotary Bars

Two types of rotary bars should be used depending on the cutting shape and material: high-speed steel rotary bars and cabled rotary bars.

1. High Speed Steel Rotary Bar

Rotary bars made of high-speed steel (HSS) are commonly used to process metals and plastics, etc. Because of its relatively high hardness and resistance to temperature changes, HSS can be used for long periods of time without wearing out the cutting edges of high-speed rotating rotary bars. HSS rotary bars are also suitable for carving and other detailed work.

2. Carbide Rotary Bar

Rotary bars made of carbide (a hard alloy) are used to process hard materials such as metal and wood. Carbide is an alloy composed mainly of metals such as tungsten and tantalum, and has very high hardness. As a result, carbide rotary bars have a sharp cutting edge and can cut smoothly even through hard materials. However, they are relatively expensive and are not suitable for long-term use.