What Is a Phthalate Resin Coating?

Phthalate Resin Coating is a highly durable coating.

Another name for Phthalate Resin Coating is Alkyd Resin, and this coating is composed of two main components: phthalic acid and polyalcohols. The choice of polyalcohols, polybasic acids, and denaturants yields resins with widely differing properties, making it possible to create a wide variety of paints for different fields of use.

Uses of Phthalate Resin Coatings

The distinctive properties of this paint are its high weather resistance and the fact that it does not discolor or deteriorate over long periods of time. It also has excellent chemical resistance, minimizing damage caused by chemicals and acidic substances.

Taking advantage of such points, it is mainly used for buildings, vehicles, ships, and machinery.

1. Exterior Walls and Roofs of Buildings

Phthalate Resin Coating is also commonly used on the exterior of buildings. Because of their durability and weather resistance, they do not discolor or deteriorate over long periods of time. In addition, the paint’s wide variety of colors and finishes help maintain the building’s appearance.

2. Vehicles

Phthalate Resin Coating is also used in the painting of vehicles such as automobiles and railcars. The paint’s curing reaction improves durability and abrasion resistance, thereby protecting the vehicle’s appearance. In addition, the paint’s color choices and gloss can be adjusted to achieve unique designs and finishes.

3. Marine Vessels

Phthalate Resin Coatings are also suitable for marine vessels that need to withstand the marine environment. They provide protection from seawater and UV rays and improve the durability of the hull. They are also resistant to sea breezes and chemicals, thus preserving the appearance of ships for a long period of time.

4. Protection of Metal Surfaces

Tartaric acid resin coatings are also effective in protecting metal surfaces. Metal is vulnerable to oxidation and corrosion, but Phthalate Resin Coating can protect metal surfaces and increase their durability.

5. Plastic Products

Phthalate Resin Coating is also ideal for plastic products. Plastics have low durability and abrasion resistance and require protection by paint. Phthalate Resin Coatings adhere to plastic surfaces and provide excellent protection.

The versatility of paint finishes also makes it possible to give plastic products an aesthetically pleasing appearance.

Principle of Phthalate Resin Coatings

The hydroxyl group of a polyhydric alcohol reacts with the carboxyl group of an acid to form a phthalate resin through a condensation reaction in which water molecules are separated. Phthalate resins have a limited range of solubility in solvents. Phthalate resins react with oxygen and harden, making them easy to adhere to painted surfaces.

Because the condensation reaction proceeds rapidly, active groups tend to remain, and they are generally used as modified resins. The most commonly used type is a dry oil-modified resin. Natural-drying Phthalate Resin Coating is composed mainly of long-oil phthalate resin, which is oxidized and polymerized by a drying agent to form a coating film.

The unsaturated double bonds of the fatty acids are extremely active and are oxidized by oxygen in the air through the catalytic action of the drying agent, producing peroxides. The principle is that this peroxide eventually decomposes and polymerizes into a network, forming an insoluble paint film.

Similarly, when a dry oil-modified resin with a relatively short oil length is used as the main ingredient, a small amount of melamine or urea resin is added to accelerate curing to produce a fast-drying, high-hardness paint.

Characteristics of Phthalate Resin Coating

The characteristic property of this paint is its high weather resistance, which means that it will not discolor or deteriorate over a long period of time. They also have excellent chemical resistance, minimizing damage caused by chemicals and acidic substances.

In addition, Phthalate Resin Coating has excellent abrasion resistance, making it resistant to physical friction and mechanical stress and allowing it to withstand long-term use. Other benefits of Phthalate Resin Coating include not only durability and protection, but also excellent aesthetic results. Available in a variety of colors and finishes, they offer unique sheen and texture.

High visibility safety clothing is a type of work clothing that improves the visual recognition of the wearer’s presence by the surrounding environment and allows the wearer to work safely.

High visibility safety clothing is a type of work clothing that improves the visual recognition of the wearer’s presence by the surrounding environment and allows the wearer to work safely.

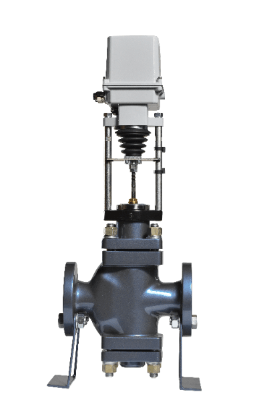

An electric valve is a machine used to regulate the flow of air or liquid by holding back or channeling it.

An electric valve is a machine used to regulate the flow of air or liquid by holding back or channeling it.