¿Qué es un Disyuntor?

Los disyuntores son dispositivos eléctricos capaces de interrumpir circuitos con flujo de corriente accidental.

Los disyuntores para baja tensión incluyen disyuntores de cableado para detectar sobrecorrientes y disyuntores de fuga a tierra para detectar corrientes de fuga. Los disyuntores para alta tensión no están equipados con detección de corriente accidental y, por lo tanto, se utilizan junto con relés de protección.

Usos de los Disyuntores

Los disyuntores de cableado también se utilizan como dispositivos de seguridad en los hogares. Originalmente, el término “disyuntor” se refiere a cualquier dispositivo que interrumpe un circuito, pero en el contexto de los cuadros eléctricos domésticos, se les conoce como disyuntores de seguridad.

La instalación de disyuntores tiene como objetivo proteger los circuitos y a las personas de corrientes accidentales, como cortocircuitos y fallas a tierra, que pueden resultar en descargas eléctricas e incendios. Por esta razón, los disyuntores se instalan en productos eléctricos y en los cuadros de distribución eléctrica.

Principio de los Disyuntores

Los disyuntores de cableado suelen ser del tipo electromagnético termodinámico, que se basa en la deformación del bimetal debido a las sobrecorrientes. Cuando fluye una corriente excesiva, se genera calor en el bimetal, lo que causa su deformación y hace que el pestillo se suelte, interrumpiendo el circuito.

Los disyuntores electromagnéticos termodinámicos se pueden restablecer manualmente una vez que el bimetal se ha enfriado y ha recuperado su forma original. Por otro lado, los disyuntores RCD (Residual Current Device) monitorean la corriente en el circuito y se desconectan si detectan una corriente de fuga. Esto se debe a que, en condiciones normales, la corriente de entrada y la corriente de salida deberían ser iguales en un circuito aislado.

La diferencia entre la corriente de entrada y la corriente de salida se conoce como corriente de fuga, y se detecta mediante el campo magnético de un transformador de corriente homopolar incorporado en el RCD. Además, los disyuntores de vacío se utilizan principalmente como interruptores automáticos para altas tensiones. Estos interruptores utilizan el vacío para extinguir el arco eléctrico que se produce al abrir un circuito conductor de corriente.

Cuando se trabaja con altas tensiones, el arco eléctrico no puede ser interrumpido fácilmente y puede dañar la zona de contacto. La capacidad de extinguir el arco eléctrico se conoce como capacidad de apagado, y los disyuntores de alta tensión están diseñados específicamente para lograr este apagado de forma segura y eficiente.

Tipo de Disyuntores

Los disyuntores que protegen contra corrientes de cortocircuito en alta tensión o tensiones especiales de alta tensión tienen, como se mencionó anteriormente, una función de extinción de arco. En función de su mecanismo de extinción de arcos, existen los siguientes tipos

1. Disyuntores de Aire (ACB)

Los disyuntores aireados se utilizan generalmente para disyuntores de bajo voltaje, ya que pueden desconectarse en el aire sin ningún problema. Los disyuntores de baja tensión comunes, como los disyuntores de seguridad, entran en la categoría de disyuntores aireados.

2. Disyuntores de Gas (GCB)

Los disyuntores que apagan el arco rociando un gas inerte sobre los contactos al abrir el circuito eléctrico. El gas hexafluoruro de azufre (SF6) se utiliza como gas inerte, pero el SF6 también es un gas de efecto invernadero, por lo que debe utilizarse con precaución en los Disyuntores.

3. Disyuntores de Aceite (OCB)

Disyuntores que utilizan aceite aislante para apagar los arcos. Hoy en día no suelen utilizarse porque su rigidez dieléctrica es inferior a la del vacío. En el pasado, se utilizaban bifenilos policlorados (PCB) y otras sustancias como aceite aislante, pero su producción ya está prohibida.

4. Disyuntores de Vacío (VCB)

Los disyuntores que extinguen un arco aplicando vacío a los contactos de apertura y cierre. Los disyuntores de vacío son el principal tipo de disyuntores pequeños de alta tensión. Tienen pocos actuadores y son fáciles de mantener.

Más Información sobre Disyuntores

Diferencia entre Disyuntores y Disyuntores

No hay diferencia entre un disyuntor y un interruptor automático. La palabra inglesa para disyuntores es breaker. Breaker es una abreviatura y en inglés un disyuntor se llama circuit breaker. La traducción literal es disyuntores eléctricos.

Cuando los ingenieros eléctricos hablan de disyuntores, la mayoría de las veces se refieren a disyuntores de alta tensión o especiales de alta tensión.

As the name suggests, a Water Quality Analyzer is an instrument designed to automatically measure the condition and properties of water.

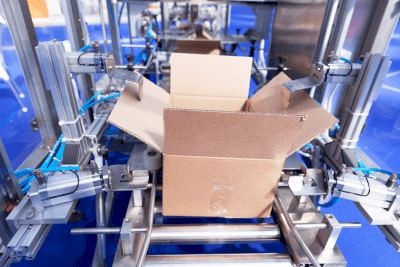

As the name suggests, a Water Quality Analyzer is an instrument designed to automatically measure the condition and properties of water. A box-making machine is a machine that assembles folded corrugated boxes into a three-dimensional structure and applies tape or hot melt to the bottom of the box, thereby reducing the need for manual labor.

A box-making machine is a machine that assembles folded corrugated boxes into a three-dimensional structure and applies tape or hot melt to the bottom of the box, thereby reducing the need for manual labor. An infrared thermometer is a device that detects the infrared radiation energy emitted from an object and

An infrared thermometer is a device that detects the infrared radiation energy emitted from an object and  A connecting cable is a cable used to connect different types of equipment.

A connecting cable is a cable used to connect different types of equipment. Washing baskets are metal baskets that are used in laboratories and manufacturing departments at companies and universities to wash several or more pieces of equipment at once.

Washing baskets are metal baskets that are used in laboratories and manufacturing departments at companies and universities to wash several or more pieces of equipment at once. There are various types of blood pressure meters, but an automatic blood pressure meter is designed to be even easier to operate than conventional products and allow anyone to take measurements.

There are various types of blood pressure meters, but an automatic blood pressure meter is designed to be even easier to operate than conventional products and allow anyone to take measurements.