What Is a Lead Screw?

A lead screw is a mechanical element that converts the rotational motion of a screw shaft into linear motion by means of a nut attached to the screw shaft.

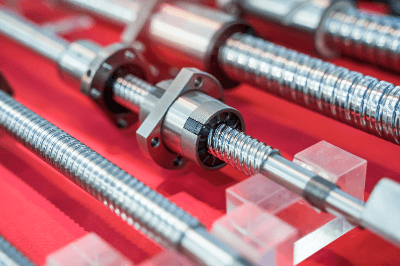

Lead screws can convert the rotational motion of a rotary motor into linear motion. There are two types of lead screws: sliding screws and ball screws that use miniature balls.

Ball screws, in particular, use balls to reduce friction and create a structure that allows smooth motion. In either case, they are indispensable mechanical elements for actuators.

Uses of Lead Screws

Lead screws are used in many manufacturing sites that require linear motion, as a wide variety of motors are manufactured and used as the typical power source for rotary motion.

In NC machine tools, they are used to move cutters and workpieces, such as the pedestal movement. Specific examples include machining centers, milling machines, grinding machines, and lathes.

In addition, lead screws are also used in industrial robots, various transport equipment, semiconductor-related equipment, injection molding machines, printing machines, color graphic printers, XY plotters, and automatic drafting machines. In automobiles, feed screws are used in mechanisms for adjusting the irradiation position of headlights.

Principle of Lead Screws

Lead screws convert rotational motion into linear motion because of the screw pitch. The continuous spiral formation of the screw allows the internally threaded parts that mesh with the screw shaft to move continuously in the axial direction where the external thread is formed.

One rotation of the threaded shaft moves the internally threaded parts by one pitch. The direction of travel can also be changed by changing the direction of rotation.

Lead screws can be either plain screws, in which the male and female threads mesh directly, or ball screws, which use balls to reduce friction. However, the principle of converting rotational and linear motion is the same for both types.

Types of Lead Screws

There are two types of lead screws: sliding screws and ball screws. Sliding screws can be further classified into the following types:

1. Triangular Screws

The screw thread has an equilateral triangular shape. The thread shape is almost the same as that of a general fastening screw. While they can be formed by thread rolling and are easy to work with, they are not suitable for parts that transmit power.

2. Trapezoidal Thread

This is a sliding screw with a trapezoidal thread profile of 29° or 30°. They are easy to process to some extent and can also be used for power transmission. The most common materials used for trapezoidal screws are carbon steel for machine structural purposes and austenitic stainless steel, which is hard and durable for general-purpose products.

3. Square Screw

The screw threads are square rectangular. Although the positioning accuracy is not high, this screw is advantageous for power transmission. These screws are mainly used in presses, jacks, and other parts that transmit large amounts of force.

Nuts used as mating parts for these Lead Screws are generally made of cast bronze or polyacetal resin (POM).

Other Information on Lead Screws

Accuracy of Ball Screws

Ball screws incorporate rolling balls to reduce friction between the rotating shaft and the nut-side parts, which move linearly with the rotational motion. Multiple parts may be combined, and international and national industrial standards have been established.

There are four accuracy grades defined by ISO standards: C0, C1, C3, C5, and C7. The smaller the number, the higher the accuracy, and the larger the number, the lower the accuracy.

C0 to C5 are used for positioning ball screws, while C7, is used for transport ball screws. The main accuracy grades of ball screws are as follows:

1. Lead Accuracy

Lead accuracy can be understood as positioning accuracy; C0 to C5 are defined by linearity and directional accuracy, and C7 is defined by travel error relative to 300 mm.

2. Mounting Accuracy

Mounting accuracy of ball screws is defined by several items. For each grade, the allowable values are specified for the circumferential runout of each part of the rotating shaft and the parallelism of the nut’s outer circumference with respect to the standard dimensions.

3. Pressurizing Torque

The preloaded torque is the torque required for positioning with ball screws. If the gap between the screw shaft, ball, and nut is large, accurate positioning is not possible. If the gap is small, torque is required for operation, which is defined by the standard.