What Is a Box Making Machine?

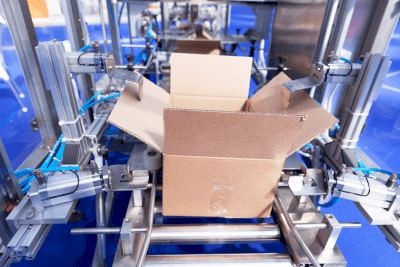

A box-making machine is a machine that assembles folded corrugated boxes into a three-dimensional structure and applies tape or hot melt to the bottom of the box, thereby reducing the need for manual labor.

A box-making machine is a machine that assembles folded corrugated boxes into a three-dimensional structure and applies tape or hot melt to the bottom of the box, thereby reducing the need for manual labor.

On the other hand, the machine that applies tape to the top surface of a box after its contents have been filled is called a box sealing machine. Some products combine the functions of both.

By incorporating fully automatic box-making machines, which are currently the mainstream, into the production line, the only work required of line workers in the box-making process is the supply of corrugated board sheets, thus achieving significant labor savings.

Applications of Box Making Machines

Box-making machines are used to assemble corrugated boxes in factories and warehouses in a wide range of industries, including manufacturing, agriculture, forestry, fisheries, and mail-order sales.

The most standard type is for assembling and taping A-type corrugated boxes (so-called “tangerine boxes”). However, there are also products that use hot-melt adhesives for gluing, as well as those for assembling one-touch boxes and trays.

Semi-automatic box-making machines perform only the folding of corrugated boxes and tape application by hand, while fully automatic box-making machines perform both box folding and tape application automatically.

Principle of Box Making Machines

In the most common type of box-making machine, which performs the assembly and bottoming of corrugated boxes, corrugated sheets loaded in the magazine section are taken into the machine one by one, the bottom flap is folded, taped, and then discharged from the machine. Electricity and air pressure are used together for power.

Different equipment is needed to assemble different types of corrugated boards. However, the size can be adjusted by operating handles and other controls for the same type of corrugated board.

Various sensors, alarms, and forecasting devices are installed to prevent such problems from occurring or to deal with them when they do occur.

On the other hand, semi-automatic box-making machines exclude the tape application mechanism found in fully automatic box-making machines, so manual work is required for box-making. However, compared to fully automatic box-making machines, semi-automatic box-making machines are sometimes used for cost-effectiveness, since they are smaller, have a simpler structure, are less expensive to install, and can be operated either by electricity or pneumatic pressure.