What Is Glue?

Glue is a material used to join substances together.

There are various types of glues, and they are selected according to the materials to be joined, the temperature at which they are used, and the time it takes for them to cure. The conditions under which glue cures also vary.

For example, some adhesives vary greatly in curing time depending on differences in temperature and humidity. In addition to the commonly known one-component glues, there are also two-component glues that cure by mixing the main agent and curing agent.

Uses of Glues

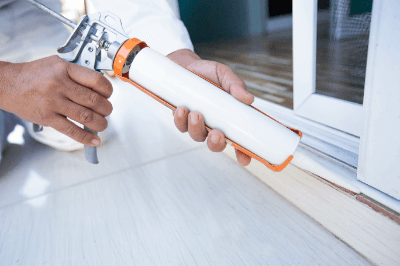

The main use of glue is to join objects together. Glues can bond various types of materials, such as metal, plastic, wood, glass, ceramics, stone, paper, cloth, leather, rubber, and foam, by selecting the appropriate adhesive for the application and object.

Common applications include machinery and automotive manufacturing, construction, electronics manufacturing, aerospace industry, and medical device manufacturing. They can also be widely used in home DIY and repair work, and in craft manufacturing.

Principle of Glues

Glue principles include mechanical, chemical, and physical interactions.

Mechanical Interaction

Glue penetrates into the pores and crevices of a material’s surface, where it cures and forms.

Chemical interaction

Glue and the object to be bonded share electrons between atoms, i.e., a chemical reaction that forms a covalent bond between the atoms.

Physical interaction

Glues are joined by intermolecular attraction, called intermolecular force or van der Waals force, which occurs when Glue and the object to be glued come close to each other on an atomic level.

Glues will function by combining one or more of these three types of interactions. Since impurities such as dirt and oil on the surface of the object can interfere with adhesion, the surface must be cleaned before bonding.

Types of Glues

Glues can be classified according to composition, shape, curing principle, and application. Below are cases classified by their curing principle.

1. Dry-Setting Glue

Glue is made by dissolving a solid adhesive component in a solvent. When the solvent evaporates from the glue, the glue solidifies, and the objects are bonded to each other. Generally, dry-setting glues are relatively inexpensive and easy to use, but they have the disadvantage of a strong solvent odor when organic solvents are used.

Woodworking glue is another type of dry-setting glue. This is a water-based emulsion of vinyl acetate resin. Because the solvent is water, it takes longer to cure, but it has the advantage of having almost no odor and being environmentally friendly.

2. Reaction Curing Type Glue

This is an adhesive in which a chemical reaction proceeds when the adhesive is removed from the container, applied to the object, and pasted together, causing the glue to harden and develop adhesive strength. Glues include two-component epoxy adhesives, one-component epoxy adhesives, and cyanoacrylate adhesives known as instant adhesives.

Two-component glues have excellent storage stability because the curing reaction is initiated when the main glue and curing agent are mixed. On the other hand, heat-curing glues and moisture-curing glues such as cyanoacrylate require careful attention in the storage environment because the curing reaction may occur in the container due to summer heat or moisture absorption.

3. Light-Curing Glue

Light-curing adhesives are adhesives that cure by light. Irradiation with light, such as ultraviolet light, generates reactive radicals and ions, which initiate polymerization of the monomer, causing the Glue to harden. In the sense that they cure by chemical reaction, they can also be called reaction-curing glues.

UV-curable glues are used to bond tiny parts in electronic and optical devices. In addition to ultraviolet light, other light sources that trigger reactions in light-curing glues include visible light and electron beams.

4. Hot-Melt Adhesives

Hot-melt glues are melted by heating to bond objects together and then hardened by cooling to form a bond. This method has the advantage of high productivity due to the short time required for Glue application and curing. It is also considered environmentally friendly because it does not contain solvents.

Hot-melt type glues are available in stick-like stick, granular, and film forms, depending on the shape of the adhesive. Stick-shaped sticks of hot-melt glue are generally inexpensive and easy to use. On the other hand, granular and film-type hot melt glues require the use of specialized equipment and are relatively expensive, but the adhesion is more precise.

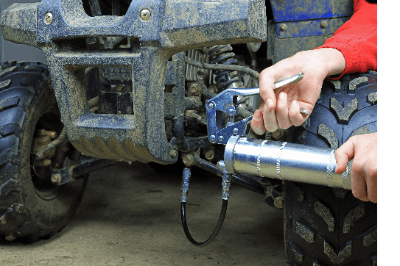

A Hydraulic Accumulator is a device that converts the pressure energy of a fluid into other high-pressure fluid energy and stores it. It is mainly used in hydraulic and steam fluid equipment.

A Hydraulic Accumulator is a device that converts the pressure energy of a fluid into other high-pressure fluid energy and stores it. It is mainly used in hydraulic and steam fluid equipment.