What Is a Caulking Gun?

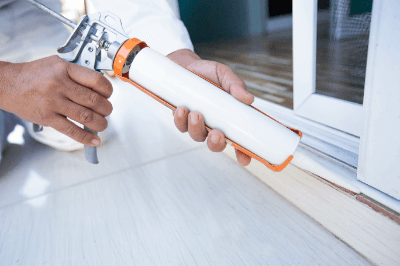

A caulking gun is a tool used to continuously apply small amounts of caulking material (also called sealant or sealant material) to fill various gaps.

It is called a caulking gun because it resembles a gun in shape, requiring the user to pull and hold a lever with a finger to dispense the caulking material.

Uses of Caulking Guns

The caulking material used to fill gaps in concrete or tile is often loaded in a cylindrical interchangeable container. One of these bottoms is formed by a conical nozzle, and the other by a raised-bottom surface.

The caulking gun is used to push this raised-bottom surface and dispense small amounts of caulking material from the nozzle.

Principle of Caulking Guns

Caulking guns can be broadly divided into the following three types

Manual Type

- This is the most common and inexpensive type and does not use power.

- By pulling out the rod that holds the container, setting it, and gripping the lever, the latch that pushes up the bottom of the container moves forward one frame at a time, pushing out the caulking material.

- The lever must be held at all times while the caulking material is being ejected, and a certain amount of grip and skill is required to apply an even amount of caulking material.

Electric Type

- The electric type has a small battery-operated motor that pushes the caulking material out, so it can dispense a consistent amount of caulking material regardless of the hardness of the caulking material.

- It is shaped like a gun and is used by pulling the trigger with the finger, so it uses very little force.

- The disadvantages are that the central unit is more expensive and heavier than the manual type.

Pneumatic Type

- This type uses compressed air to push out caulking.

- It is lighter than the electric type and more stable than the manual type.

- The disadvantage is the need for a compressor to make compressed air and to work with a connected hose.

Recommendations for Choosing Caulking Guns

Sealing is an essential part of the gap-filling process. Caulking guns were initially tools used in construction work and plumbing. In recent years, however, DIY has become popular and used in ordinary households.

Therefore, a novice handling a caulking gun for the first time may be at a loss as to which caulking gun to choose. Here are some recommendations for selecting a caulking gun to avoid making a mistake in choosing to caulk.

A typical sealant cartridge contains a 330 ml capacity. If you are working over a large area, you will need more cartridges. If you need a large amount of sealant, a large cartridge with a 600 ml or 800 ml capacity is suitable. We recommend that you purchase a caulking gun that is compatible with those cartridges.

Functionality is also an essential factor in choosing a caulking gun. If the caulking gun has a rotating body, it can be used in areas that are difficult to seal. Another advantage is that it eliminates the need to change posture or hold the gun in different positions depending on the area to be worked on, which improves work efficiency.

Dripping can cause the sealant to adhere to unexpected places and waste sealant. This is very inefficient and a cause of failure. Caulking guns that prevent dripping instantly release the pressure on the sealant by releasing the trigger.

The type of caulking gun determines other methods. Categorized as manual, electric, or pneumatic, caulking guns vary in price, lightness, and weight. To avoid mistakes, choose the right caulking gun for you.

How to Wash Caulking Guns

When sealant adheres to the caulking gun, it hardens. Therefore, it cannot be removed by ordinary washing with water. However, if you leave it as it is, the hardened solids will get in the way, and you may not be able to set the sealant the next time you work with it.

To wash the caulking gun, first, use disposable rubber gloves. This is because kerosene and solvents are suitable for removing sealant. Solvents, in particular, can be dangerous in direct contact with the skin.

Be careful to be safe and keep your caulking gun clean.