What Is an Electromagnetic Field Meter?

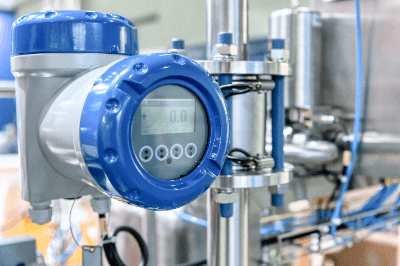

An Electromagnetic Field (EMF) Meter is an instrument used to measure the strength of electric fields.

It is mainly used to measure the strength of radio waves received by radios and televisions, as well as to measure radio waves emitted by electronic devices. In recent years, there has been a significant increase in the us of electronic devices that emit radio waves.

The risk of radio interference among electronic devices and the potential impact of radio waves on the human body are both on the rise. As such, there is a great need for Electromagnetic Field (EMF) Meters that can accurately measure the electric field strength.

Applications of Electromagnetic Field (EMF) Meter

The Electromagnetic Field (EMF) Meter is designed to measure the strength of radio waves, and so is used to investigate the installation location of devices that receive radio waves and to inspect the safety of devices that output radio waves.

When investigating the installation location of equipment that receives radio waves, EMF Meters are useful for assessing antenna installations for TV broadcast reception and identifying potential interference with TV reception. In recent times, there has been growing demand for measuring WiFi radio wave strength.

Electromagnetic Field (EMF) Meter is used in safety inspections of equipment that outputs radio waves. It helps to reduce the risk of radio interference from equipment that generates radio waves and ensure compliance with electromagnetic field bio-safety guidelines, minimizing potential adverse effects of radio wave on the human body.

Principle of Electromagnetic Field (EMF) Meter

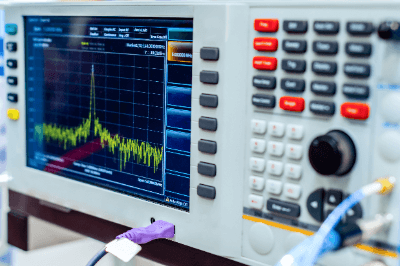

The most common method of measuring the strength of radio waves is to use an Electromagnetic Field (EMF) Meter to measure the voltage induced in an antenna with a known gain. The measured value is converted to an antenna with an effective length of 1 m and expressed in [dBμV/m].

1. Radio Wave Strength in Space

Electromagnetic Field (EMF) Meter has different measurement methods depending on the application. To measure the radio wave strength in a space, an electric field probe is simply directed towards the target device. Typically, the electric field probe uses an EO modulator (electro-optic modulator) to detect the intensity of the radio waves.

In the absence of an electric field, light input from a light source in the field probe passes through an optical fiber, is reflected by an EO crystal, and then passes through another optical fiber before being output.

However, when an electric charge is present, the EO crystal alters the refractive index of the light. Consequently, the output light exhibits a different refractive index than the input light. By converting the modulated light into intensity information using a photodetector, the Electromagnetic Field (EMF) Meter measures the strength of the electric field.

2. Radio Wave Absorption in the Human Body

In order to examine the radio wave absorption efficiency of the human body, etc., a device called a phantom must be inserted between the device under test and the electric field probe.

The phantom has the same electrical characteristics as the human body. The field probe of the Electromagnetic Field (EMF) Meter consists of an optical fiber, an EO crystal, and a glass tube covering it. The EO crystal exhibits the EO effect, in which the refractive index of light changes depending on the electric field present. The modulated signal is then detected by a photodetector.

Other Information on Electromagnetic Field (EMF) Meter

1. Electromagnetic Field (EMF) Meter Kits

The major difference between commercially available inexpensive assembled kits of Electromagnetic Field (EMF) Meter and those sold by the manufacturer is the significant difference in performance, convenience, and versatility. For example, in the case of inexpensive kits, the display is an analog pointer meter.

On the other hand, the manufacturer’s Electromagnetic Field (EMF) Meter has a color LCD display, can store the obtained data in memory, and can communicate with other devices. Therefore, it can be said that Electromagnetic Field (EMF) Meter kits are more for educational or temporary use.

2. Electromagnetic Field (EMF) Meter App

In recent times, WiFi signal strength can be measured with Electromagnetic Field (EMF) Meter apps. However, a little care is needed in the settings. When setting up a wireless network, the coverage area will hardly change.

However, the signal strength is weakened as it passes through obstacles like furniture and walls. So is interference caused by other wireless networks in the vicinity, causing the WiFi signal to progressively weaken as one move away from the source router.

When users get a strong signal, they get fast page loads and instant downloads. In order for the router to send a strong signal where it is needed, it is important to choose the right location and configuration of the router for the best results.

Recently, there are apps that display a visual map of the router wireless range. These apps also show information about other WiFi networks and the field strength of the WiFi signal. They visualize the signal strength of the wireless network as a handy heat map to assist in determining where to place the router.

A logic analyzer is a device primarily used to verify the operation of digital circuits.

A logic analyzer is a device primarily used to verify the operation of digital circuits. A solder pot is a container that holds or is filled with molten solder and equipped with a

A solder pot is a container that holds or is filled with molten solder and equipped with a