What Is an Encoder?

An encoder is a device that converts changes in position into electrical signals and outputs them.

Encoders that measure rotation angle are called rotary encoder, while those that measure linear displacement are called linear encoder.

Methods for measuring position change can be classified into incremental and absolute methods. Light, magnetic force, electromagnetic induction, etc. are commonly used for measurement.

Uses of Encoders

Encoders are mainly used in machines that use motors, among which stepping motors and servo motors are typical motors that use encoders.

1. Stepping Motors

Stepping motors are motors whose rotational speed and angle can be accurately controlled by pulse signals.

The interval between pulses and the number of pulse signals applied to the motor determine the angle and speed of rotation, enabling accurate positioning, which is why stepping motors are used in manufacturing and other fields.

Not all stepping motors use encoders. There are two types of stepping motors: open-loop stepping motors, which do not use encoders or feedback control, and closed-loop stepping motors, which use encoders and feedback control.

The open-loop method is a simpler system than the closed-loop method, but it always applies the maximum current to prevent “stalling,” which is the inability to keep up with the pulse speed.

2. Servo Motors

A servo motor is a motor that has a mechanism to maintain a constant speed of continuous linear or rotational motion by precisely controlling the distance traveled and angle of rotation in a single control.

It is a three-piece set consisting of encoders, a brushless AC motor (the mainstream) or a DC motor, and a servo amplifier. AC motors are currently the most common type of motor used in machines that require precise motion control. Examples include industrial robots, automobiles, elevators, and automatic guided vehicles. They are used in many factories, especially now that factories are becoming more and more automated.

When selecting encoders, consider measurement accuracy, resolution, reaction time, size and shape, durability against vibration and shock, and protection against the operating environment.

Principle of Encoders

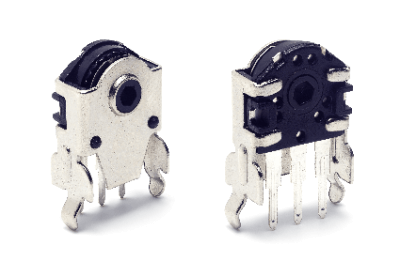

Encoders are classified into optical, magnetic, and electromagnetic induction types according to the detection method.

1. Optical Encoders

Displacement can be measured by shining light on a rotating disk with evenly spaced holes attached to a rotating shaft and detecting the period of light passing through the holes. Since light has little effect on machines, it is widely used in general.

Optical encoders can be classified into two types according to the output signal: incremental and absolute. Each method is explained below.

- Incremental method

The incremental method measures position displacement by measuring the number of times light passes through a hole in a rotating disk.

- Absolute method

The absolute method measures position displacement by detecting absolute position signals assigned to each hole of the rotating disk.

2. Magnetic Encoders

Displacement is measured by utilizing the magnetic field of a magnet attached to the rotating shaft, which fluctuates due to rotation.

3. Electromagnetic Induction Encoders

Displacement is measured by detecting electromagnetic induction generated by a coil mounted around a rotating shaft.