What Is Flowmeter?

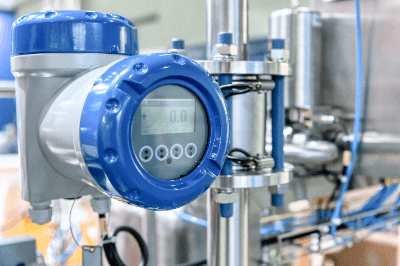

A Flowmeter is a device used to measure the volumetric or mass flow rate of a fluid flowing through a pipe.

Many measurement principles have been developed to properly measure various types of flow depending on conditions such as pressure and temperature. Flow types include gas, liquid, and multiphase flows.

Some products can be installed outside of the piping to measure flow. However, many flowmeters are designed to be installed inside the piping for flow measurement. Therefore, the installation of a flowmeter should be carefully considered either before the piping is installed or during the design phase.

Uses of Flowmeter

Flowmeters are widely used in manufacturing where fluids are used, including chemical and petroleum plants, automotive, semiconductor, pharmaceutical, and food industries.

More than ten (10) different operating principles have been developed for flow meters, and the appropriate flow meter must be selected according to the fluid being handled.

Flowmeters installed in pipes can disrupt the flow. Therefore, the selection should be based on consideration of the extent of this impact. The frequency, time, and cost of maintenance should also be considered.

Types of Flowmeters

The following is a brief introduction to the types of flowmeters and their respective mechanisms, principles, and advantages.

- Volumetric flowmeter

- Coriolis flowmeter

- Ultrasonic flowmeter

- Electromagnetic flowmeter

- Thermal flowmeter

- Karman vortex flowmeter

- Area flowmeter

- Turbine flowmeter

- Differential pressure flowmeter

- Vortex flowmeter

- Flow cell flowmeter

1. Positive Displacement Flowmeter

A positive displacement flowmeter consists of a pipe with the same inside diameter as the piping to be measured, a rotor, and a rotation detector. The fluid flowing through the pipe rotates the rotor, and the flow rate is measured by detecting the rotation speed.

The structure is simple and highly accurate, but the use of gears can lead to problems such as entanglement.

It is used for for measuring the flow rate of fluids like fuel oil and lubricating oil, which have relatively stable densities. Due to its high accuracy, it is well-suited for applications such as fuel oil trading.

2. Coriolis Flowmeter

The Coriolis flowmeter consists of two U-tubes, a vibrating machine, and a force sensor. The Coriolis flowmeter utilizes the principle of Coriolis force, in which two oscillating U-tubes with fluid flowing through them generate forces in opposite directions to each other.

While the Coriolis flowmeter has the disadvantage of being long due to its measurement principle, it does well at directly measuring mass flow. It has high accuracy and responsiveness, and is widely used when the density of a fluid is also to be measured at the same time.

On the other hand, it is less effective in environments with vibrations or when measuring fluids that contain bubbles.

3. Ultrasonic Flowmeter

An ultrasonic flowmeter consists of an ultrasonic generator and a measuring instrument. The flow rate is calculated by measuring the propagation time of ultrasonic waves and the Doppler effect caused by the reflection of ultrasonic waves. This flowmeter can measure from the outside of the piping.

It has the advantage of non-contact fluid flow measurement, allowing the flowmeter to be retrofitted onto existing piping. It can also be installed cost-effectively, even on large-diameter piping.

However, it is not well-suited for applications that require highly accurate flow measurement due to errors caused by factors such as pipe wall thickness.

4. Electromagnetic Flowmeter

Electromagnetic flowmeter calculates the flow rate by measuring the electromotive force generated by the coil component within the device. This electromotive force is influenced by the velocity of a magnetic material placed inside the fluid to be measured.

Many of these meters do not need to be installed in the pipe, and are used when maintenance costs for in-pipe flowmeters, such as those used for contaminated water, are high.

Electromagnetic Flowmeter is used to measure the flow rate of slurry mixed with solids because it has no moving parts and does not obstruct the flow of fluid. However, it cannot measure non-conductive fluids, such as oil.

5. Thermal Flowmeter

A thermal flowmeter consists of two temperature sensors and a heater. It calculates the flow rate by measuring the difference between the fluid’s temperature before and after it is heated by the heater. This measurement is then converted into a flow rate. The thermal flowmeter is known for its ability to handle a wide range of temperatures.

Thermal flowmeter can measure corrosive gases since it is a non-contact gas flowmeter. In addition, there is almost no pressure loss and mass flow rate can be measured. However, it may not be suitable for the measuring theflow rate of gases that already contain contaminants.

6. Area Flowmeter

In an area flowmeter, a float within a vertically tapered tube interrupts the flow from bottom to top, resulting in a pressure difference before and after the float. The meter rests at a position where the weight of the float and the force of the pressure difference are balanced. By reading this position, the flow rate can be determined.

It is used to measure the flow rate of liquids, gases, purge fluids, and more. Its straightforward construction makes it cost-effective, although it does not provide very high measurement accuracy.

7. Turbine Flowmeter

The turbine flowmeter is positioned within the flow and calculates the volumetric flow rate based on the number of revolutions of the impeller. It utilizes the fact that the rotational speed of the impeller, which has an axis parallel to the flow, is directly proportional to the flow velocity.

The lightweight design allows for a high degree of freedom in installation. Due its lightweight, inexpensiveness, excellent repeatability, and responsiveness, it is well-suited for measuring large volumes of fluid. However, it has a short-service life due to bearing deterioration.

8. Differential Pressure Flowmeter

Differential pressure flowmeter uses an orifice to create a pressure loss and measures the flow rate by utilizing the pressure difference between the primary and secondary sides.

It is characterized by its low-cost and wide range of applications. Actual flow calibration is not required.

9. Karman Vortex Flowmeter

The Karman vortex flowmeter consists of an obstacle designed to generate Karman vortex and a vortex measuring instrument. The flow rate is calculated by measuring the Karman vortex.

Karman vortex is a regular vortex generated in the wake of an obstruction.

Karman vortex flowmeter can measure a wide range of fluids since there are no mechanical operating parts or electrodes. However, it cannot be used in high-vibration environments due to the length of straight pipe required and the possibility of malfunctions caused by vibration.

It is used to measure steam and clean water.

10. Vortex Flowmeter

A vortex flowmeter is a flowmeter that uses the Karman vortex. A Karman vortex is an alternating sequence of regular vortices that occur downstream of an object (vortex source) placed in the fluid flow.

11. Flow Cell Flowmeter

A flow cell flowmeter is a type of orifice flowmeter that generates differential pressure by installing an orifice in the piping through which water or air flows and measures the differential pressure using a float installed in the tributary stream.