What Is a Differential Probe?

A differential probe is a device that, when measuring signals with an oscilloscope or similar device, detects noise generated from locations unrelated to the device transmitting the signal. This includes ground vibration, called common noise, and amplifies the measurement signal with an amplifier to make it easier to measure.

In communications such as USB and HDMI, it is necessary for the output side to detect signals accurately. If differential probes are used incorrectly, they can be broken or may not provide accurate output.

In many cases, differential probes are available from the same company that sells oscilloscopes, and since they have excellent connectivity, it is best to purchase a differential probe from the same company as the oscilloscope.

Uses of Differential Probes

Differential probes are used in the prototyping and testing phases of many communication devices, such as USB, HDMI, DisplayPort, Ethernet, and SATA, to detect noise with an oscilloscope and determine whether the noise is affecting the product or not. The differential probes are used to check for noise in USB, HDMI, DisplayPort, Ethernet, SATA, and other communications.

Differential probes are often expensive, so it is important to properly investigate whether they meet the standards for use before purchasing.

Principle of Differential Probes

A differential probe consists of two active probes that are identical in nature. One active probe is connected to the positive terminal of the connection of the device transmitting the signal to be measured, and the other to the negative terminal. By measuring the difference between the signals detected by these two probes, common noise can be detected.

Many differential probes are available on the market that have been devised to facilitate measurement of waveforms on an oscilloscope. For example, low-voltage signals can be amplified by an amplifier to make them easier to measure on an oscilloscope, some voltages can be grounded to avoid loading the oscilloscope with high-voltage signals, and signals can be made into clear square waves.

If the differential probe is properly selected according to the signal to be used, a clear noise measurement can be made.

Other Information on Differential Probes

1. Equivalent Circuit of a Differential Probe

A differential probe consists of two active probes, which are connected directly from the tip of the probe to the input end of a semiconductor circuit, so the input capacitance can be as small as 1pF, which is extremely small. On the other hand, unlike passive probes that use an attenuator, input resistance is in the tens of KΩ to 1MΩ range.

Therefore, when a differential probe is connected to a high-impedance circuit to measure waveforms, it is necessary to consider the measurement results in light of the influence of the probe. An effective way to do this is to connect the equivalent circuit of the differential probe to the circuit under test and simulate the effects.

In the case of a differential probe, between one pin and GND, the input resistance and input capacitance published by the manufacturer are connected in parallel. Similarly, the other pin and GND are connected in parallel with the input resistor and input capacitance. Thus, between the two pins of the differential probe, the input resistance is doubled and the input capacitance is halved. The effect of this impedance on the circuit under test should be taken into account when judging the measurement results.

2. Active Probe

Probes are used to measure stable signals. Without a probe, circuit operation would be affected by the capacitive component of the cable. This has a particularly strong effect on high frequency measurements.

Active probes use a semiconductor element at the input end. The input capacitance of the active probe itself is also very small, and some probes have input capacitances smaller than 1pF.

The input capacitance of the probe also affects the waveform. Passive probes have a larger capacitance component than active probes, and ringing, which is an oscillation of the waveform at the rising edge of the pulse, is significant.

3. High-Voltage Differential Probes

Differential probes are suitable for observing floating signal portions, but common probes have withstanding voltages of only 30 V to 100 V for both differential and ground voltages. Large high-voltage probes are required to measure floating points in circuits that handle high voltages, such as commercial power supplies. Probes with specifications of 6,000 V or more for differential voltage and 2,000 V or more for ground voltage are commercially available.

In measurements using high-voltage differential probes, the distance between the two pins must be sufficiently far apart to avoid the risk of discharge. As a result, ringing occurs in the high-frequency range due to the impedance of the lead wires, resulting in large amplitude fluctuations. As a countermeasure, twisting the two lead wires is effective.

4. Common Mode Noise

Noise in electric circuits can be broadly divided into differential mode noise and common mode noise. Differential-mode noise is noise conducted through conductors in a circuit.

Common mode noise, on the other hand, is noise that is partially conducted back through the earth or enclosure, and is noise in phase with the input signal and the signal on return. Common-mode noise is considered difficult to counter because of the complexity of how the noise propagates.

High-voltage differential probes are a very effective means of testing the operation of switching power supplies. Switching regulators generate common-mode noise with ground voltage fluctuations of several hundred volts.

Although a differential probe should cancel the ground voltage fluctuations and allow observation, it is inevitable that a small amount of the ground voltage fluctuation will actually be added to the differential output. To reduce the effect of this variation, it is necessary to select a probe with excellent CMRR (Common-Mode Rejection Ratio).

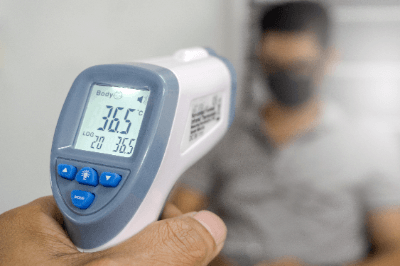

A non-contact temperature sensor is a sensor that can detect temperature without being directly attached to the object being measured.

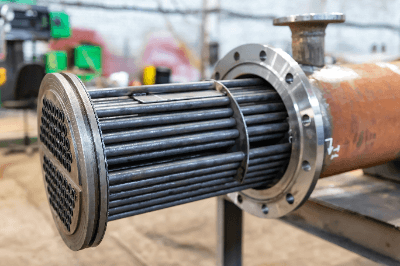

A non-contact temperature sensor is a sensor that can detect temperature without being directly attached to the object being measured. A heat exchanger is a device that transfers heat between fluids, such as air and water.

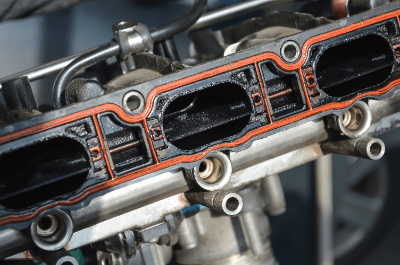

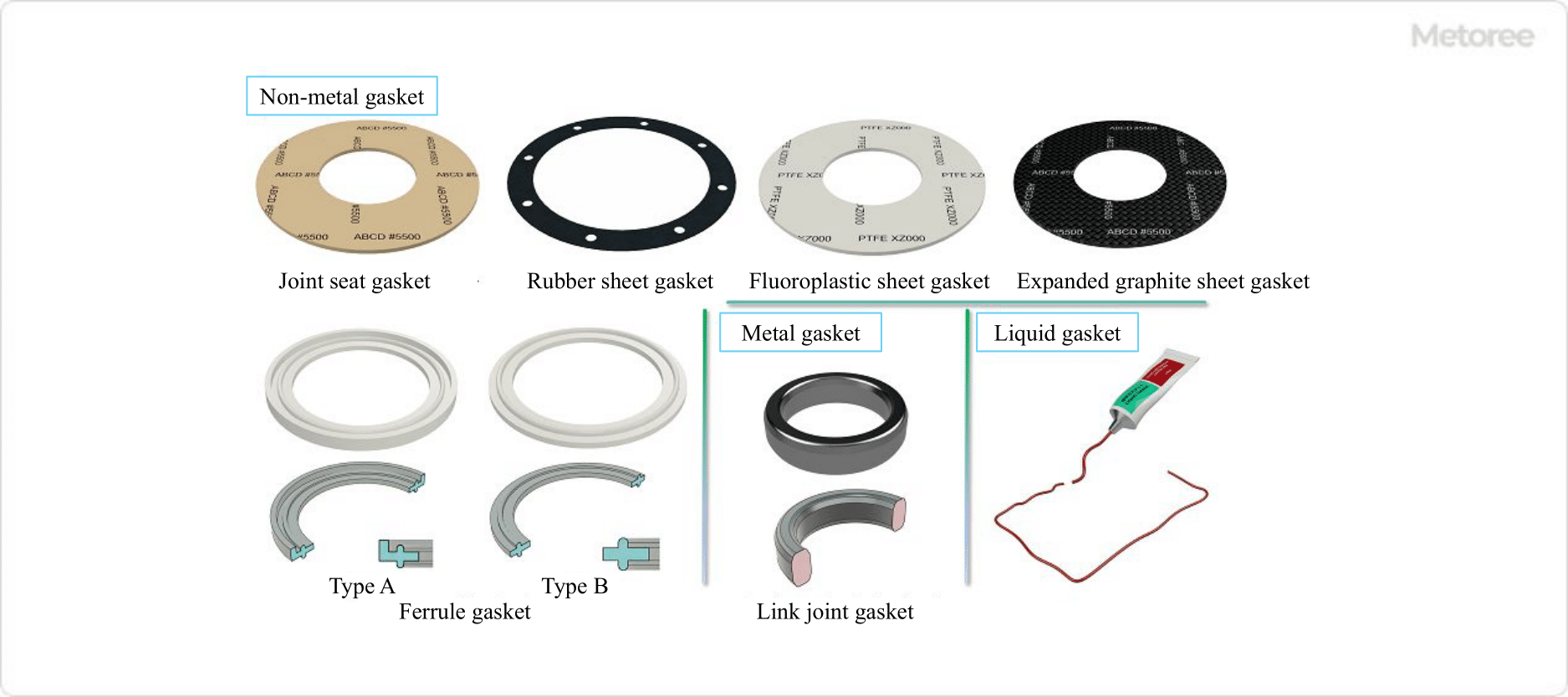

A heat exchanger is a device that transfers heat between fluids, such as air and water. A gasket is a part or material used in equipment, structures, piping, etc. to maintain airtightness and sealing to prevent internal fluids from leaking out.

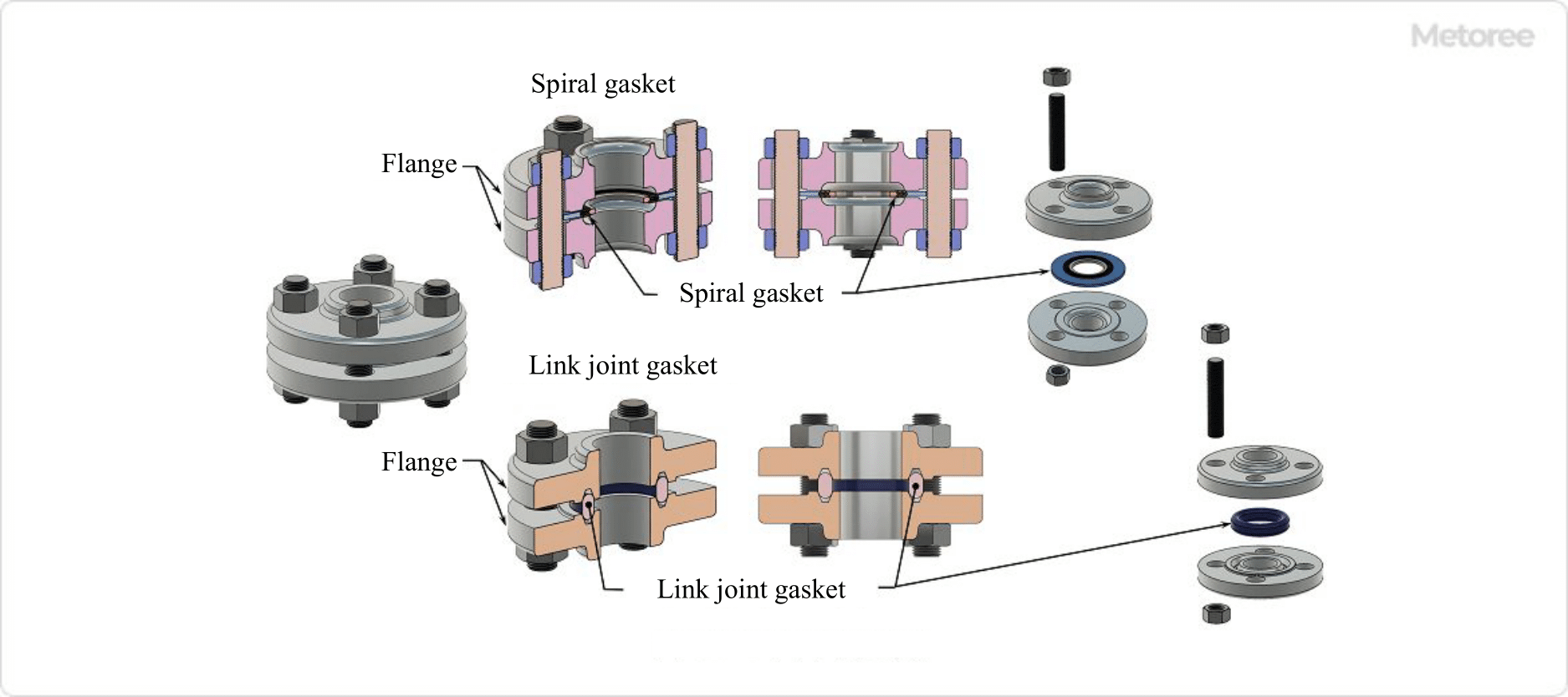

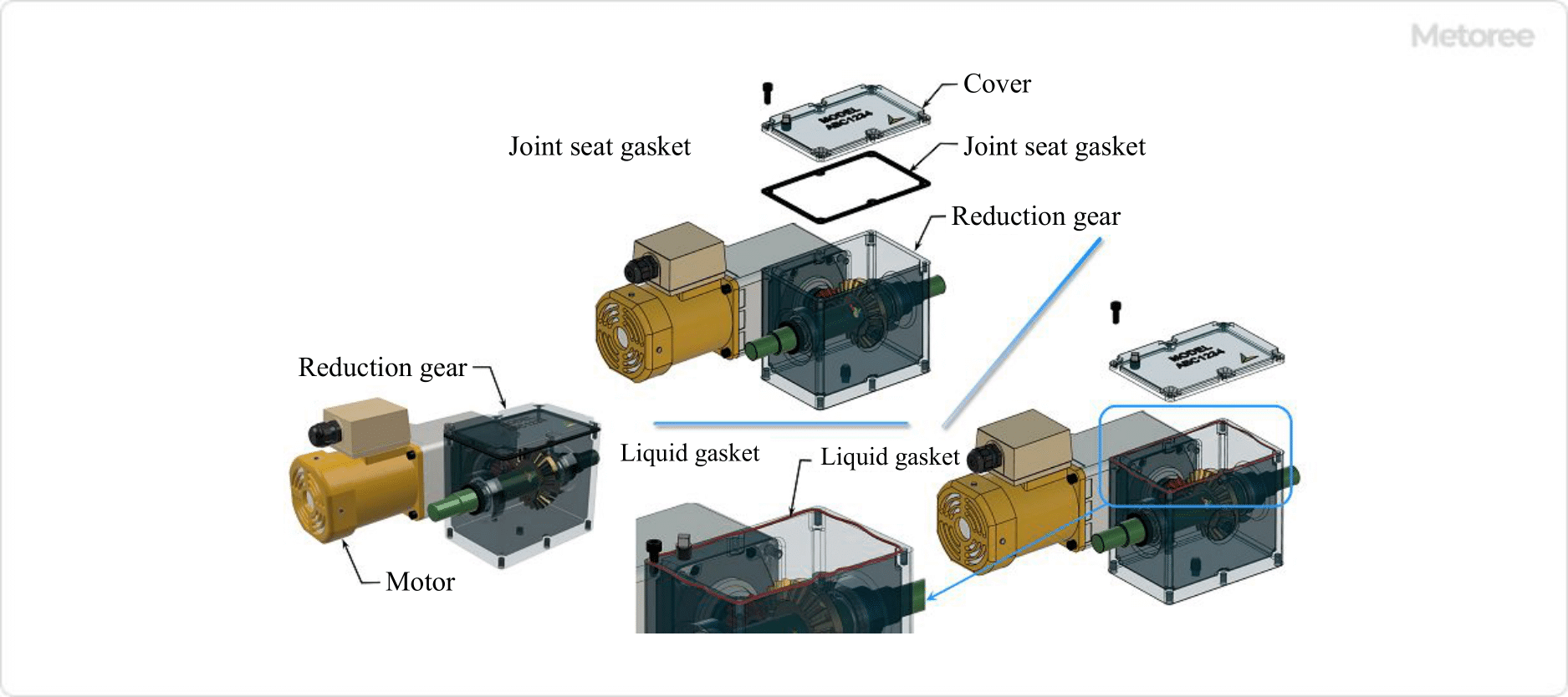

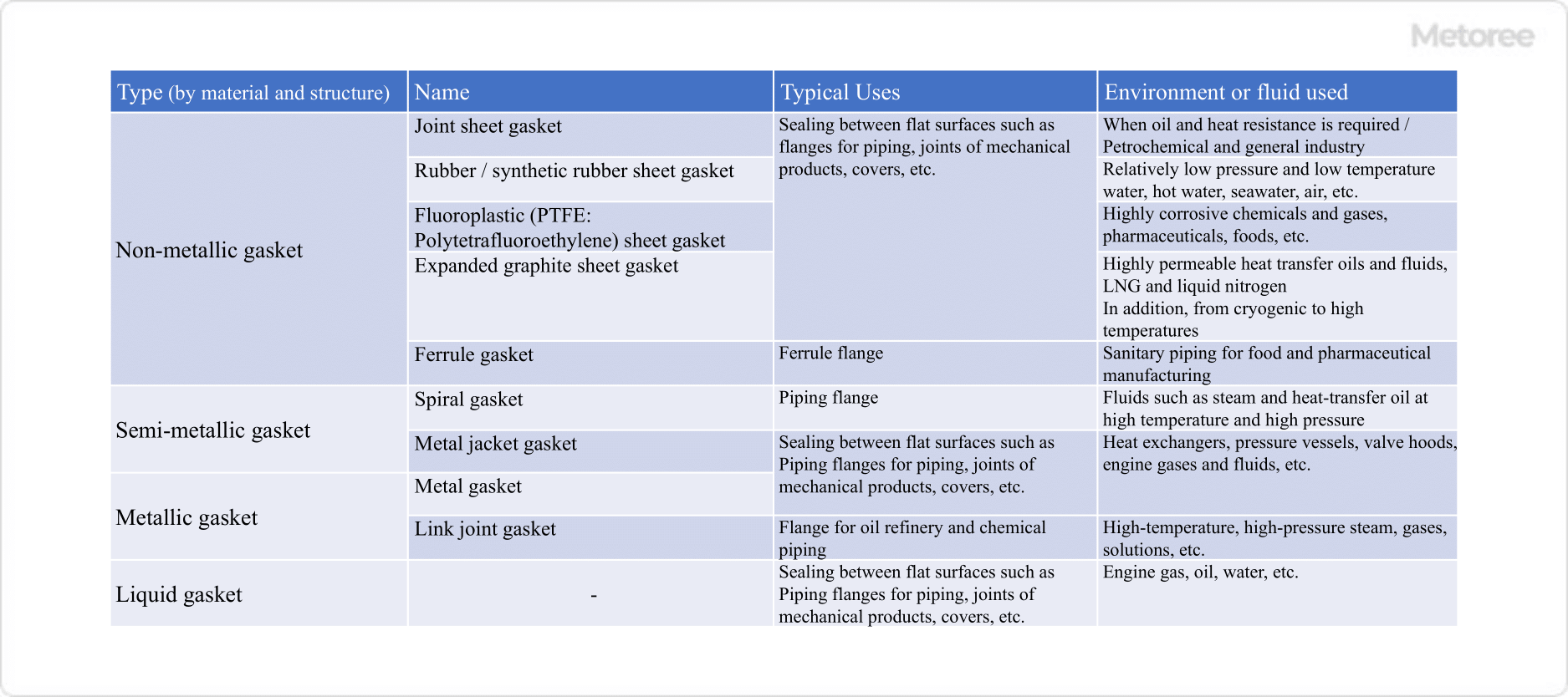

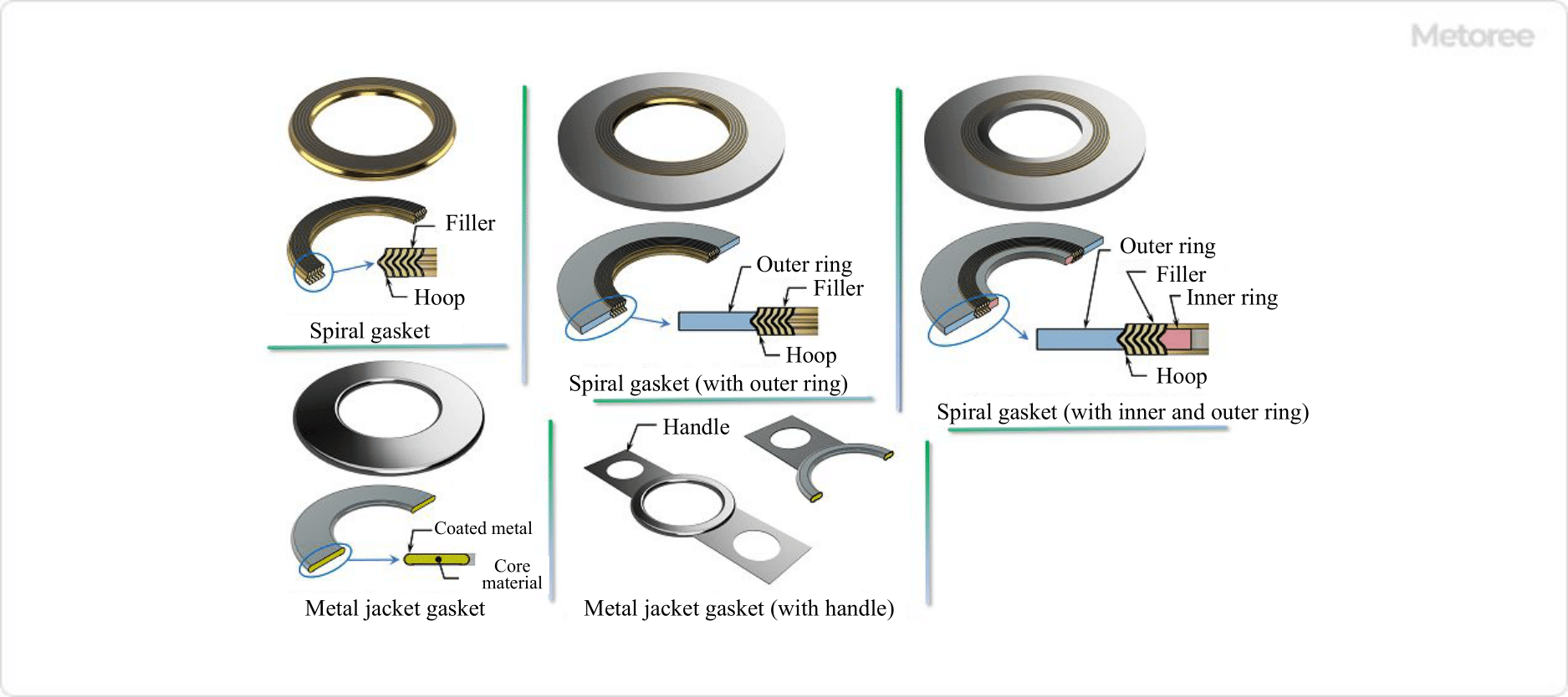

A gasket is a part or material used in equipment, structures, piping, etc. to maintain airtightness and sealing to prevent internal fluids from leaking out.

A compressor is a machine that compresses and pumps gas through the rotary motion of a rotor or the reciprocating motion of a

A compressor is a machine that compresses and pumps gas through the rotary motion of a rotor or the reciprocating motion of a  A pulse generator is a device that generates rapidly occurring and converging electrical signals called pulses.

A pulse generator is a device that generates rapidly occurring and converging electrical signals called pulses.