What Is a Gasket?

A gasket is a part or material used in equipment, structures, piping, etc. to maintain airtightness and sealing to prevent internal fluids from leaking out.

A gasket is a part or material used in equipment, structures, piping, etc. to maintain airtightness and sealing to prevent internal fluids from leaking out.

In general, there are two types of gaskets and packings for sealing purposes. Gaskets are mainly used for “motionless” or “non-moving” parts. Gaskets are mainly used for “motionless” or “non-moving” parts, while packing is mainly used for “moving” or “movable” parts.

Uses of Gaskets

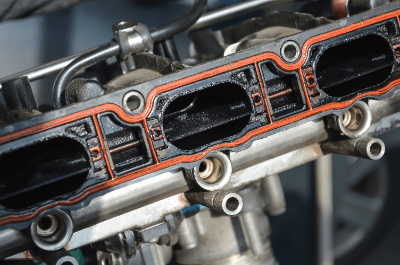

Figure 1. Example of gasket use (1)

Gaskets are used to fill and seal gaps in flat areas such as pipe flanges, machine joints, and covers. The main reason is to prevent leakage of internal fluids by maintaining and sealing tightness, but they are also used to prevent foreign matter from entering through gaps in joint surfaces.

Figure 2. Example of gasket use (2)

Generally, gaskets are inserted between joint surfaces and tightened with screws or bolts to enhance sealing by the surface pressure.

Principle of Gaskets

Gaskets are inserted between joints of piping flanges or machine parts, tightened by screws or bolts, compressed to a certain thickness and shape, and sealed by the surface pressure. Therefore, the proper tightening method and tightening force of gaskets vary depending on the material, thickness, shape, structure and material.

In particular, for gaskets for pipe flanges and pressure vessel flanges, the following standards specify the tightening method and control method. It is necessary to refer to these standards and each manufacturer’s proper tightening surface pressure for optimum tightening management.

- Japanese Industrial Standard JIS B2251:2008 Tightening method for flange joints

- Japanese Industrial Standard JIS B8265:2010 Structure of Pressure Vessels General Items

- Japan Petroleum Institute Standard JPI-8R-15-2008 Tightening control of flanges and bolts

- ASME ASME PCC-1-2013 Guidelines for Pressure Boundary Bolted Flange Joint Assembly

In general, when used for flanges, the tightening force required to seal the fluid is the bolt load (tightening force) in service (Wm1) and the bolt load (tightening force) when tightening the gasket (Wm2), as specified in JIS B8625.

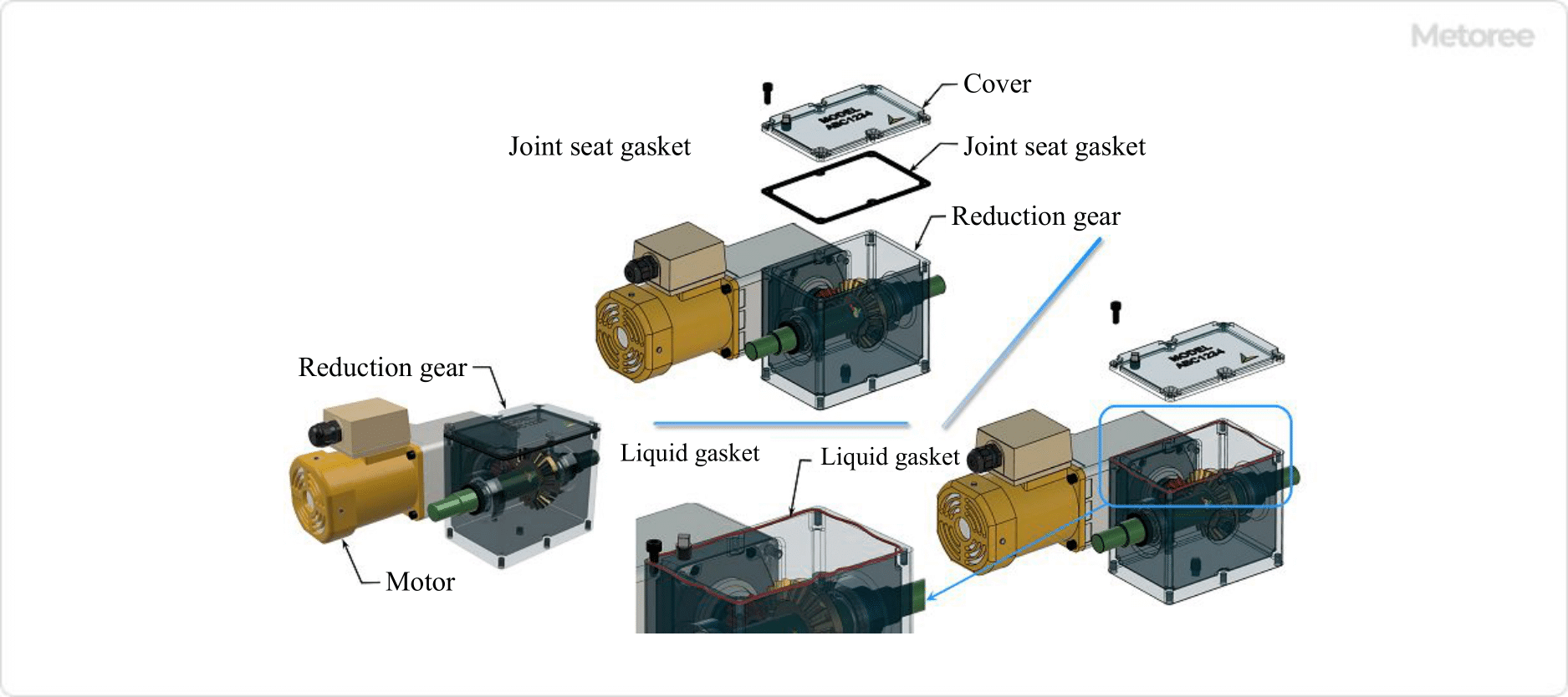

Liquid gaskets are applied to the joint surface and tightened to form a uniform, hardened, adhesive thin film that provides a tight seal.

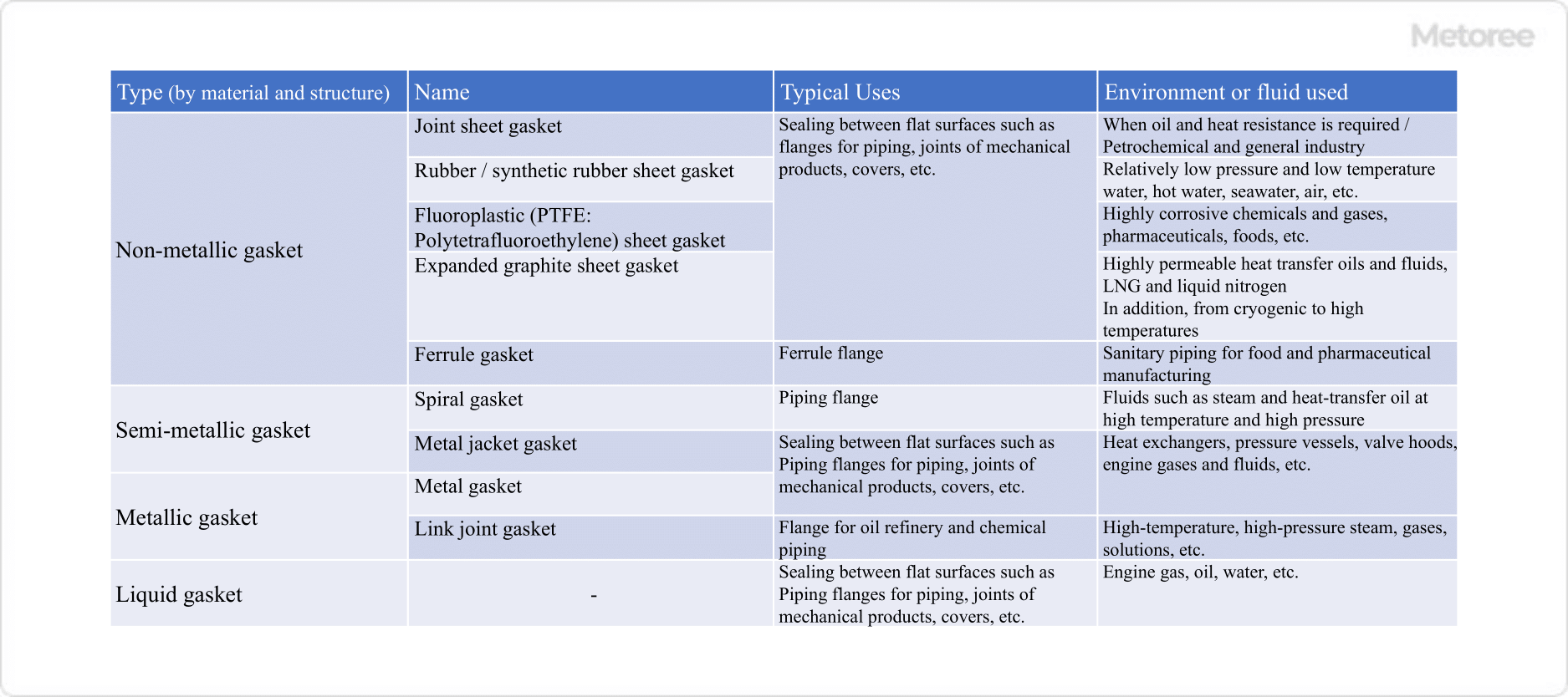

Types of Gaskets

There are various types of gaskets, depending on the material, shape, and structure. See the table below for the main types.

Figure 3. Types of gaskets

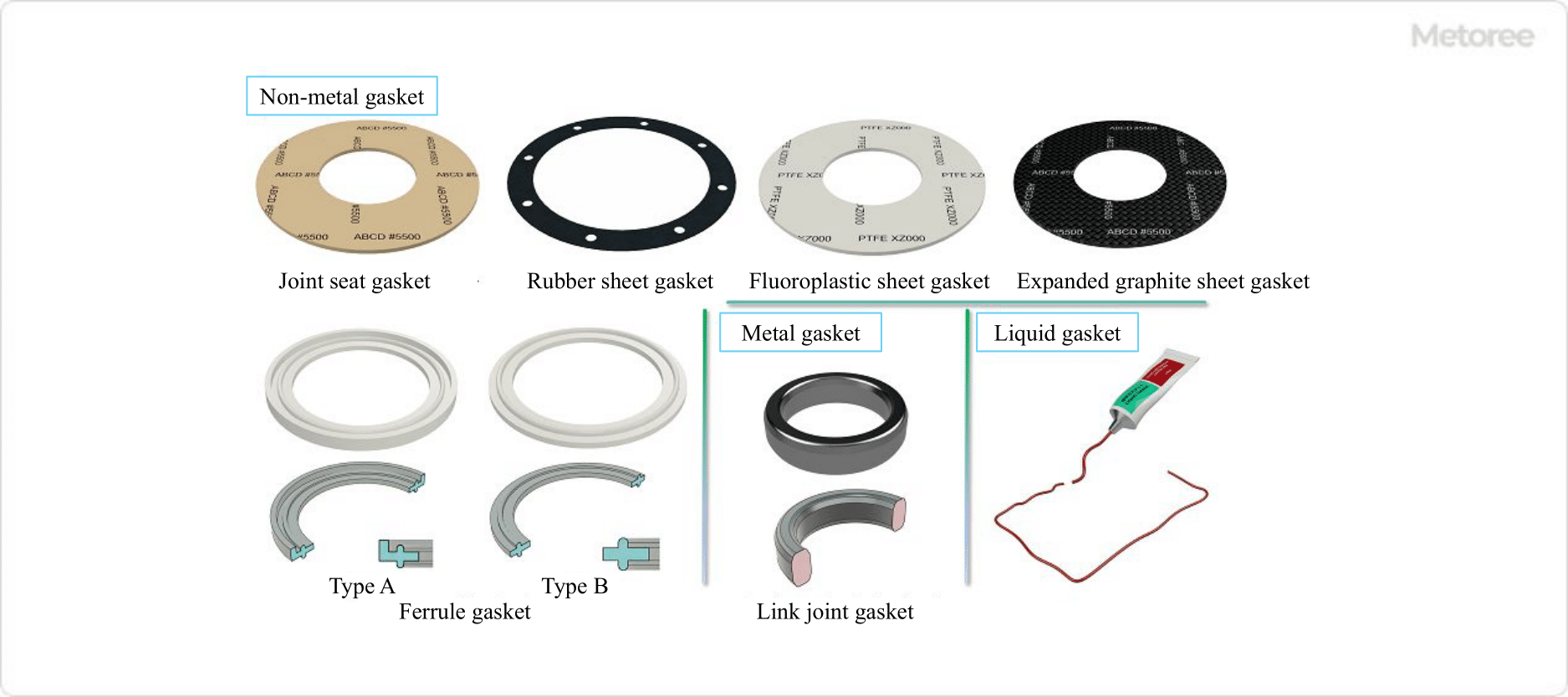

1. Non-metallic Gasket

Joint Sheet Gasket

Joint sheet gaskets are gaskets made by adding rubber and fillers to glass fiber material, rolling, and vulcanizing to form a sheet. The sheet material is punched or cut to the size and shape of the joint surface of piping flanges and machine parts. They are used in a wide variety of situations, with a high degree of dimensional flexibility, and are used in a wide range of applications, from high and low temperatures to high and low pressures, and are also highly versatile with excellent oil and heat resistance.

Rubber and Synthetic Rubber Sheet Gaskets

Rubber and synthetic rubber sheet gaskets are sheet gaskets made of natural rubber, nitrile rubber, silicon rubber, and other materials. They are punched or cut to the required size and shape. They are used for relatively low-pressure and low-temperature fluids.

Fluoroplastic PTFE Sheet Gasket

This gasket is a sheet of fluoroplastic PTFE compression-molded gasket. Inorganic fillers and carbon-based fillers are added to improve heat resistance, chemical resistance, acid resistance, and alkali resistance. They are used for highly corrosive chemicals, food piping flanges, and equipment.

Expanded Graphite Gasket

These gaskets are made of graphite that has been treated with chemicals, heated to a high temperature for expansion, and formed into a sheet shape. They are punched or cut to the required size and shape. Since the sheet by itself has low strength, some are reinforced by sandwiching or laminating a thin stainless steel plate between them to increase strength.

It has excellent heat and chemical resistance, and is used for flanges and equipment in general-purpose piping. They are also used for flanges of piping for highly permeable fluids, cryogenic LNG and liquid nitrogen.

Ferrule Gasket

The Herule gasket is a standard gasket that conforms to the Herule flange for sanitary piping. Materials include ethylene-propylene rubber (EPDM), fluoroplastic (PTFE), and silicone rubber. These gaskets are used in flanges for food, pharmaceutical and chemical piping, and equipment.

2. Semi-metallic Gasket

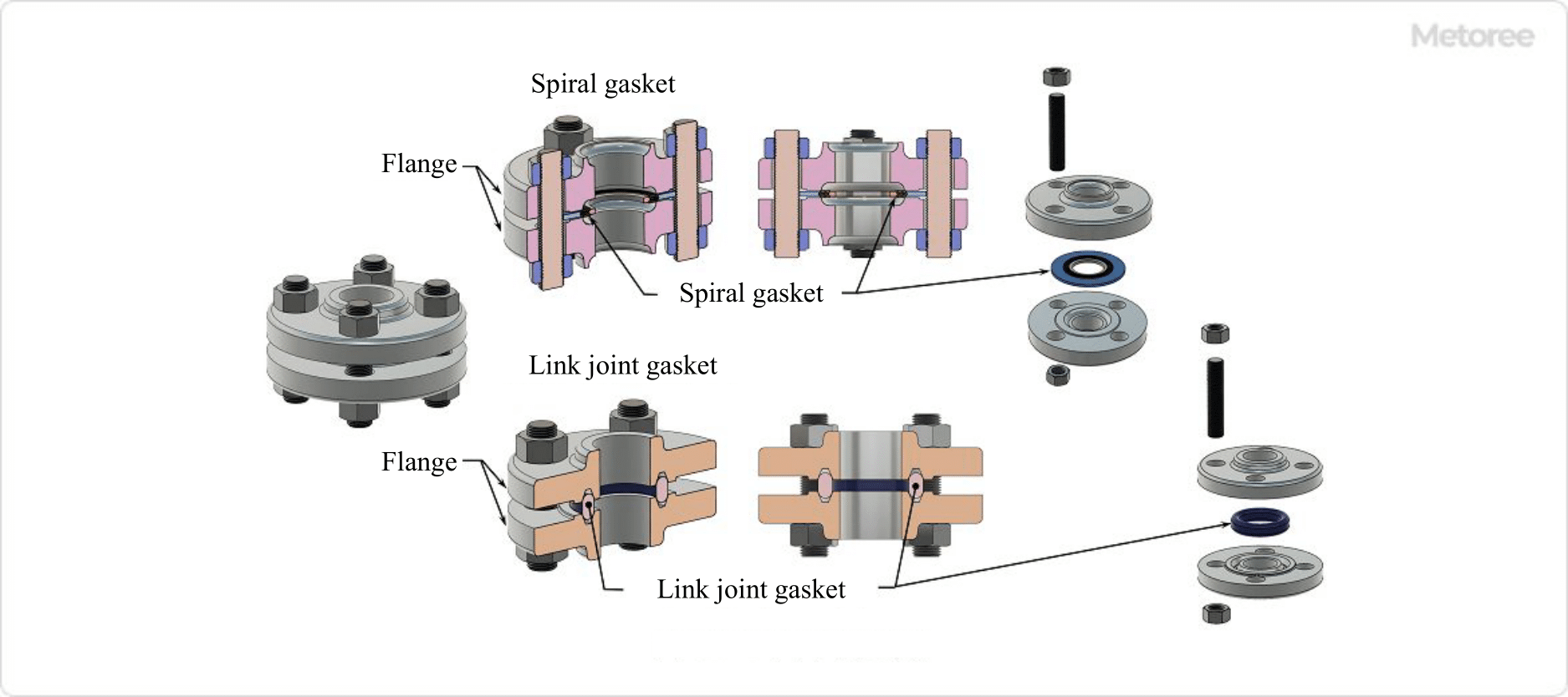

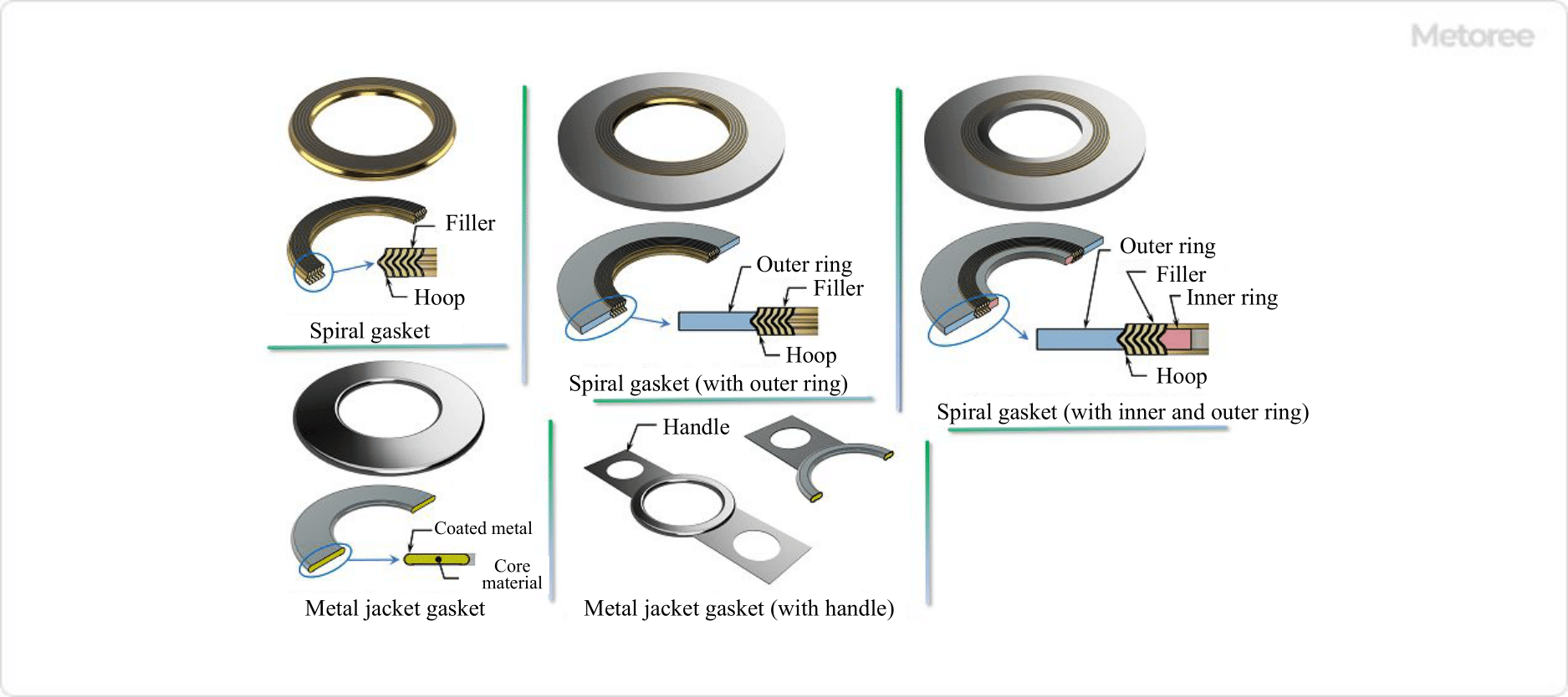

Figure 4. Semi-metallic gasket

Spiral Gasket

A spiral gasket is a gasket consisting of a hoop of thin iron or stainless steel sheet formed into a V-shaped cross section and a buffer material of the same shape, such as expanded graphite, fluoroplastic PTFE, or non-asbestos paper, alternately wrapped around the hoop.

The state consisting of hoop and filler is the basic form. In addition to the basic type, there are gaskets with an outer ring for proper positioning of the flange joint surface and with an inner ring to reduce deformation due to tightening force. These gaskets are used for flanges for fluid piping such as high-temperature, high-pressure steam and heat-transfer oil.

Metal Jacket Gasket

Metal jacket gaskets are gaskets consisting of a highly heat-resistant core material (cushioning material) wrapped around a thin coated metal plate of carbon steel, stainless steel, copper, or Monel (nickel-copper alloy). They are used for high-temperature, high-pressure, acid- and alkali-resistant piping flanges and equipment joints such as heat exchangers and pressure vessels.

Figure 5. Non-metallic gasket, metallic gasket, and liquid gasket

3. Metal Gasket

Metal Gasket

Metal gaskets include “metal corrugated gaskets,” which are thin mild steel or stainless steel sheets bent into a corrugated cross section and processed into a ring shape; “metal flat gaskets,” which are single sheet rings of mild steel or stainless steel sheets; and “saw-tooth gaskets,” which are circular V-shaped grooves processed on the back surface of a flat shape. These gaskets are used for cylinder block and cylinder head joint surfaces of engines and flanges for high-temperature, high-pressure piping.

Ring Joint Gasket

Ring joint gaskets are made by machining forged metal into a ring shape and fitting it into a ring groove on the flange joint surface. The cross section of the ring can be oval, octagonal, hexagonal diamond, triangular delta, or round.

Materials include mild steel, stainless steel, Monel (nickel-copper alloy), titanium and aluminum. They are used in equipment joints such as flanges for high-temperature, high-pressure steam, gas, and oil piping, and pressure vessels.

4. Liquid Gasket

Liquid gaskets are used in a variety of situations, such as PVC pipes for rainwater drainage and engine joints. They are low-cost because they are effective even when applied in small quantities, and because they blend well with the joint surface, they provide good sealing even at low tightening surface pressure and relatively low machining accuracy, and they require no retightening, which makes them highly efficient in operation.

There are several types, including organic solvent (modified alkyd-based, fiber ester-based, synthetic rubber-based), solvent-free (phenolic-based, modified ester-based, silicone-based, acrylic-based), and water-based types (water-based acrylic-based).