What Is a Heat Exchanger?

A heat exchanger is a device that transfers heat between fluids, such as air and water.

A heat exchanger is a device that transfers heat between fluids, such as air and water.

A typical device that uses a heat exchanger is an air conditioner, a machine that regulates room temperature by a heat exchanger between a refrigerant and air. Various structures have been developed, and appropriate selection is necessary according to the fluid used for heat exchange.

Uses of Heat Exchangers

Heat exchangers are used in a variety of applications, from household appliances to industrial applications.

The following are examples of heat exchanger applications:

- Air conditioning equipment, such as home air conditioners and water heaters

- Radiators in cars

- Commercial refrigerators in frozen food plants

- Gas temperature control in process plants

- Steam turbine condensers and coal economizers

- CPU cooling in computers

In the home, heat exchangers are used in air conditioners and refrigerators. They maintain the required temperature by transferring heat from the room or inside the cabinet. Heat exchangers are also used in water heaters and floor heating systems.

There are countless examples in industry. Factories with industrial furnaces use industrial water or seawater to cool their jackets in heat exchangers. Heat exchangers are also widely used in infrastructure facilities such as power plants, and condensers in steam power generation are also a type of heat exchanger.

Heat exchangers such as heat sinks are used to cool computers. This is a product with many heat sinks, which are installed directly on the heat-generating medium and use the ambient air as a cooling medium.

Principle of Heat Exchangers

A heat exchanger consists of piping and fins.

Piping is the structure through which the medium to be heated or cooled flows. Generally, they are made of metal, and a variety of products are available, such as stainless steel and copper, depending on the application. When a fluid that serves as a heat source flows through it, it is called a heat medium pipe, and when a fluid that serves as a cooling source flows through it, it is called a refrigerant pipe.

A fin is a structure that efficiently dissipates heat. Aluminum is often used because of its excellent heat transfer characteristics. They are attached to the piping in the form of pleats.

Depending on the direction of flow of low-temperature fluid and high-temperature fluid, there are two types: countercurrent and parallel flow. When they flow in opposite directions, they are of the countercurrent type, and when they flow in the same direction, they are of the parallel flow type. Generally speaking, the directional flow type is more efficient for heat exchange.

Types of Heat Exchangers

Typical types of heat exchanger structures include multi-tube heat exchangers, plate heat exchangers, and spiral heat exchangers. Other types include air-fin type, fin-tube type, and coil type.

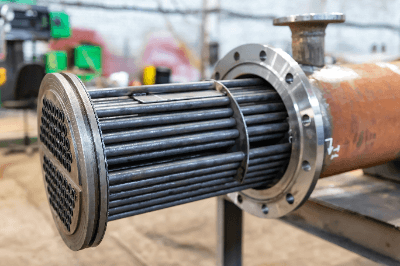

1. Multi-Tube Heat Exchanger

A multi-tube heat exchanger consists of a thick circular tube and many thin circular tubes inside the circular ring. The fluid to be exchanged flows into the thick tube, and the refrigerant or cooling water flows into the thin tube. Since each pipe is partitioned, the fluids do not mix and heat is exchanged between them.

2. Plate Type Heat Exchanger

This heat exchanger consists of a number of specially processed metal heat transfer plates that are stacked on top of each other, and the high-temperature fluid and low-temperature fluid flow alternately across the plates.

This heat exchanger easily achieves a turbulent flow effect and a high heat exchange rate. They also have the advantage of a compact design and are less likely to cause problems in terms of installation location. Because of the stacked structure of the heat transfer plates, the number of plates can be changed according to the process requirements. However, it is difficult to use this type of heat exchanger with fluids that have high viscosity or contain particles, as these fluids can cause blockage between the plates.

3. Spiral Type Heat Exchanger

A spiral heat exchanger is a heat exchanger that exchanges heat between two fluids in a spiral-shaped flow path where the two fluids do not mix.

The inside of the channel is a single flow path, and even if a substance adheres to the walls of the heat exchanger, it can be peeled off from the walls. This is because the channel width is shortened and the flow velocity is increased. Therefore, it is suitable for the heat exchange of fluids containing impurities.

4. Air-Fin Heat Exchanger

This heat exchanger consists of a tube and a fan. It is used for cooling. The fluid to be cooled flows through the tube and is cooled by air flowing through it using the power of the fan.

5. Finned Tube Heat Exchanger

This type of heat exchanger has fins (heat-transfer plates) installed on tubular tubes to increase the heat-transfer area. This type of heat exchanger is used in air conditioner heat exchangers.

6. Coil Type Heat Exchanger

This is a heat exchanger in which the heat transfer tubes are coiled and the outside is surrounded by a cylinder or the like. A cooling or heating medium is inserted into the tube to exchange heat with the tube side.