What Is a Cleanroom?

A cleanroom is a room in which the cleanliness of the air is controlled.

A cleanroom is a room in which the cleanliness of the air is controlled.

A cleanroom is a space in which airborne particles and microorganisms are controlled to a cleanliness level below a certain level. Materials, chemicals, and water supplied to the room are also maintained at the required cleanliness level, and environmental conditions such as temperature, humidity, and pressure are controlled as needed.

The cleanliness of the air can be checked by counting the size and number of particles in the air using particle sensors. Cleanrooms are used in the manufacture of products where dust and particulates are a major problem. Cleanrooms are called by various names, such as dust-proof rooms, sterilization rooms, and bio-clean rooms, depending on the intended use.

Uses of Cleanrooms

Cleanrooms are used in the manufacture of industrial products such as semiconductors, liquid crystals, and electronic components. This is because even the smallest dust particles can have a significant impact on product quality.

Especially in the front-end process of semiconductors, cleanrooms with the highest level of cleanliness, Class 1 to 10 in the US Federal Standard, and Class 3 to 4 in the ISO standard, are used. Factories that manufacture precision equipment, such as electronic components and optical machinery, and factories that handle chemicals and food products, require ISO Class 5 to 7 cleanrooms.

Cleanrooms are also widely used in other industries, such as printing, paint, lenses, and films.

Principles of Cleanrooms

1. Prevention of Particulates From Humans

Cleanrooms maintain cleanliness by preventing particulates of human origin from entering the room and by capturing them with high-performance filters. In order to maintain the cleanliness of a cleanroom, it is first necessary to reduce the amount of dust, germs, sweat, hair, and other debris emitted by humans.

Depending on the required level of cleanliness, workers change into special white dustproof clothing and shoes, put on gloves, and wear caps to keep hair out. In addition, safety glasses and masks may be used. When entering the cleanroom, the workers are given an air shower to wash the dust from their bodies.

2. Purification of Indoor Air

The air taken in through the intake ports in the cleanroom is circulated and purified of particulates and other contaminants by high-performance filters called HEPA filters installed in the air outlets. The cleanliness of the cleanroom can be monitored by a particle sensor.

Cleanrooms are also airtight, and are designed to prevent unnecessary particulates from entering from the outside by adjusting the air pressure in the room.

Types of Cleanrooms

Cleanrooms can be broadly classified into two types: those used for precision equipment manufacturing, or those used for food production and medical or life science research. Cleanrooms used in medical and life science research institutions are specifically referred to as bio-cleanrooms or sterile rooms.

In industrial applications, dust in the air is expected to be eliminated, but in bioclean rooms, in addition to this, it is necessary to prevent contamination by microorganisms such as bacteria and viruses.

Other Information on Cleanrooms

1. Cleanroom Standards

Cleanrooms are further classified according to the number of particles per unit volume of air. In Japan, three types of standards are used for classifying clean rooms: the U.S. Federal Air Ductility Standard (FED), the ISO standard.

U.S. Federal Clean Air Standard FED209E

The U.S. Federal Standard for Air Quality, FED209E, was discontinued in 2001 and replaced by the ISO standard 14644-1, but the industry still uses the widely used FED in many cases.

FED

The FED is classified into six categories, from Class 1 to Class 100,000, with the class number representing the number of particulates per unit volume. In other words, the smaller the class number equates to a higher level of cleanliness.

ISO Standards

ISO standards are further subdivided into nine (ISO) classes, from Class 1 to Class 9, in addition to the six classes corresponding to the FED standards.

2. Cleanroom Systems

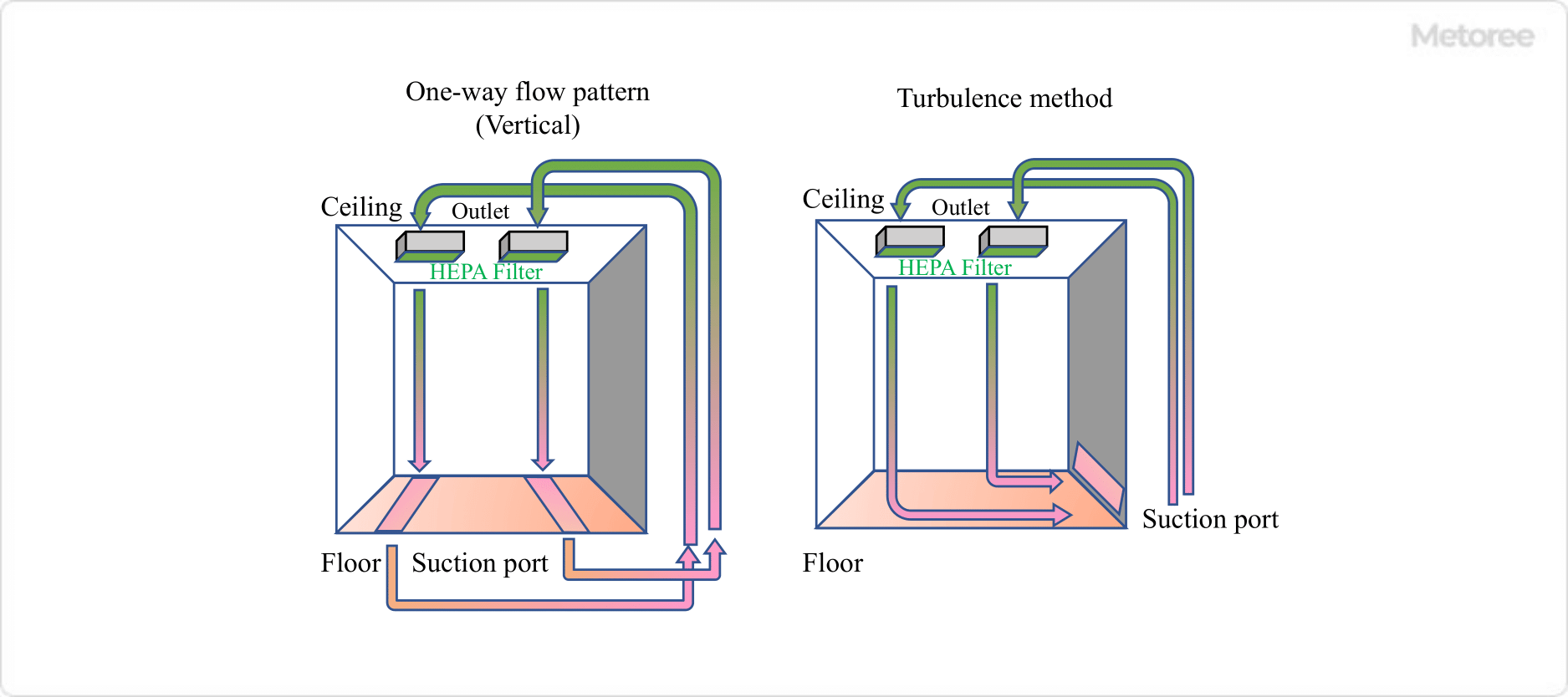

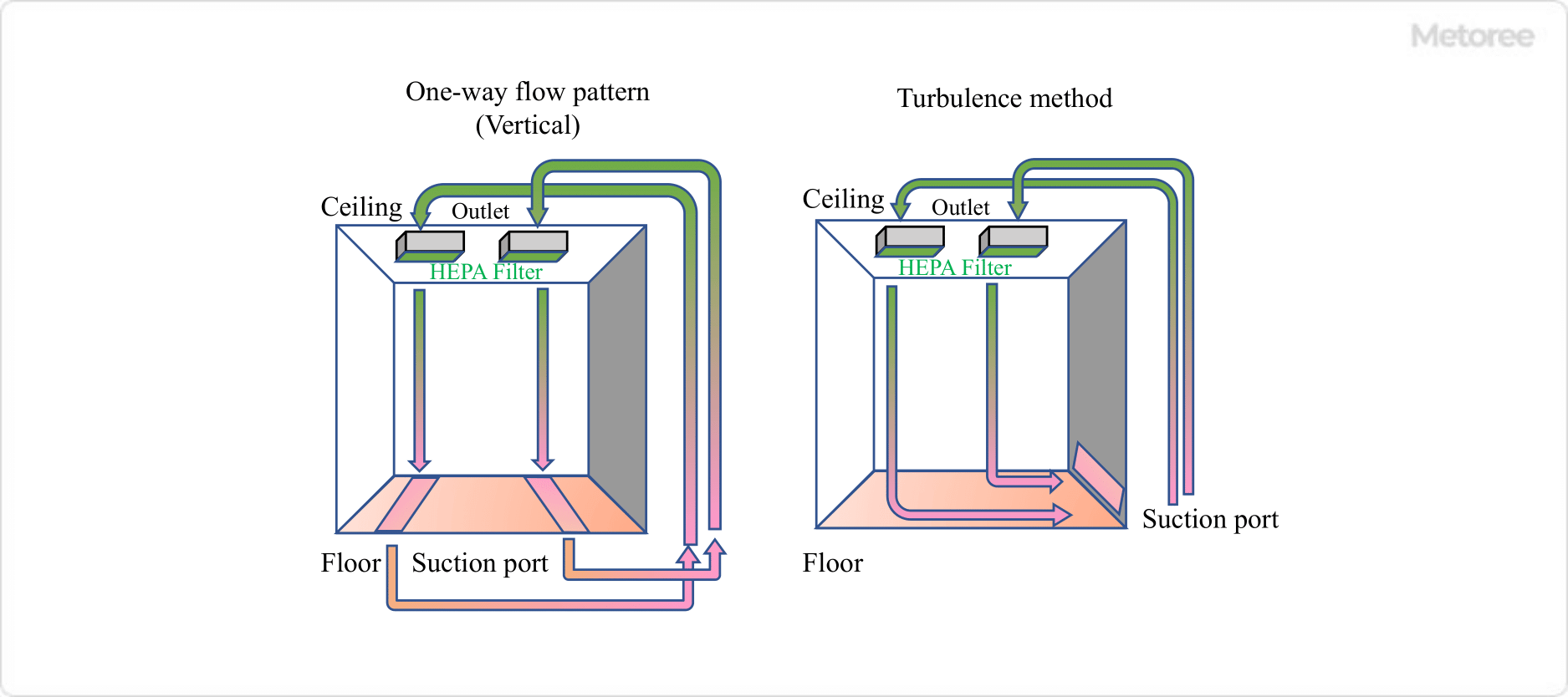

Figure 1. Clean room system

Cleanrooms can be classified into two types according to the way in which air is circulated, i.e., the way in which airflow is created: the unidirectional flow method and the turbulent flow method.

Unidirectional Flow Method

In the one-directional flow method, the air outlets and inlets are installed facing each other to create a uniform air flow. If a ceiling vent and floor inlet are installed, a uniform airflow can be created vertically. If a vent is installed on one wall and an inlet on the opposite wall, a uniform airflow can be created horizontally.

The unidirectional flow method can maintain a high level of cleanliness because the airflow is constantly circulating.

Turbulent Flow Method

The turbulent airflow method is a method in which the air outlets are installed on the ceiling and the intake ports are installed on the wall. Because there are areas where airflow stagnates, the cleanliness is inferior to that of the unidirectional flow method, but the advantage is that it can be introduced and operated at a relatively low cost.

A barcode printer is a machine that prints barcodes, which are bar and number representations of various types of information, on a specific sheet of paper.

A barcode printer is a machine that prints barcodes, which are bar and number representations of various types of information, on a specific sheet of paper. A metal film resistor is a

A metal film resistor is a

A cleanroom is a room in which the cleanliness of the air is controlled.

A cleanroom is a room in which the cleanliness of the air is controlled.