What Is a Gouging Rod?

A gouging rod is a carbon rod for gouging using a welding machine.

A gouging rod is a carbon rod for gouging using a welding machine.

The purpose of gouging is to remove defective areas that occur during welding. An arc is generated between the carbon gouging rod and the metal plate to melt the metal around the defective area, and at the same time, the molten metal is mechanically removed to groove the metal plate.

Note that arc refers to arc welding using the electrical discharge phenomenon. It refers to a welding method in which the base metal and gouging rod are melted by the high heat of the arc generated between the base metal and the gouging rod.

Uses of Gouging Rods

Gouging rods are used in the arc-air method. The arc-air method is a method of digging trenches by melting a metal base material with an arc and blowing the molten metal away with a high-speed air jet.

Major applications include steel frames, bridges, shipbuilding, and can manufacturing. It can be used for cutting the back of welds, cutting bevels, or defects in welds, or it can be used for cutting castings, such as the pouring of castings or the opening of a hot water tank, or for cutting nests.

Other applications include U-shaped beveling, cutting, and drilling of mild steel plates, and processing of cast iron and cast steel repair welding.

Principle of Gouging Rods

In air-arc gouging using a gouging rod, a gouging rod is placed between a torch and a base metal, and a DC or AC arc is generated between this electrode and the base metal to melt the material locally while blowing it away with air to dig a groove.

There is another method that does not use air, but uses an AC or DC welding machine and a welding rod with a special flux applied to the mild steel core wire. Beveling of stainless cast iron, mild steel, cast steel, and various alloy steels, removal of defects such as grooves and cracks, and drilling of holes can be easily performed by adjusting the current and the angle between the welding rod and base metal.

The angle of the welding rod to the base metal should be 10 to 30°. If the angle is smaller than this, the workability is better, but the welding rod wears out more rapidly. Conversely, if the angle is larger, deep penetration is possible, but the flow of molten metal is reduced.

Types of Gouging Rods

1. Gouging Rod for Direct Flow

DC gouging rods can be used in many ways, including beveling, cutting, drilling, and flaw removal on steel plates.

2. Alternating Current Gouging Rod

AC gouging rods are made of special high-grade raw materials to completely solve the arc difficulty inherent in AC. Outstanding arc safety improves work efficiency and economy.

3. DC Hollow Gouging Rod

DC hollow gouging rods are ideal for digging a smooth gouging trail. With a regular gouging rod, the depth of the gouging moat is dug sharply, but with a hollow, the current is not concentrated at the tip, making it easier to dig a shallow, U-shaped bottom.

Other Information About Gouging Rod

Gouging Methods

There are two methods of gouging using gouging rods:

1. Air Carbon Arc Gouging Method

The air carbon arc gouging method is a method of removing defects by melting the base metal by generating an arc between the gouging rod and the base metal. When the base metal is melted, air is injected along the gouging rod to remove the molten metal.

The air carbon arc gouging method is more efficient than conventional methods and can be used for stainless steel. Another advantage is that it has less impact on the base metal.

2. Plasma Arc Gouging Method

Plasma arc gouging method is a method using plasma cutting and transitional plasma arc. The high-density, high-temperature energy of the plasma arc causes little deformation after gouging and can be applied to any metal.

Another advantage is that the work can be automated and does not generate as much noise and dust as the air carbon arc gouging method. Therefore, the plasma arc gouging method is often used for gouging.

SFP (small form-factor pluggable) modules are

SFP (small form-factor pluggable) modules are  A burnishing drill is a tool that can perform both drilling and burnishing at the same time.

A burnishing drill is a tool that can perform both drilling and burnishing at the same time. A bug filter is a type of dust collection device that uses a woven or non-woven filter

A bug filter is a type of dust collection device that uses a woven or non-woven filter  A biomass plastic is a polymer material chemically or biologically synthesized from renewable biomass resources.

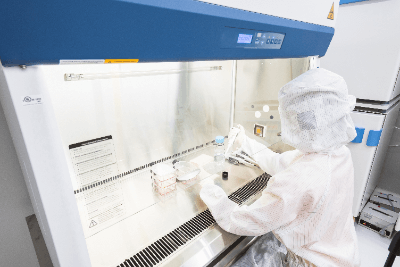

A biomass plastic is a polymer material chemically or biologically synthesized from renewable biomass resources. A draft chamber is a type of local exhaust ventilation system used when handling hazardous substances that may affect the human body in chemical or biological experiments.

A draft chamber is a type of local exhaust ventilation system used when handling hazardous substances that may affect the human body in chemical or biological experiments. A torque hinge is a type of hinge used for opening and closing doors.

A torque hinge is a type of hinge used for opening and closing doors.