What Is a One-Touch Fitting?

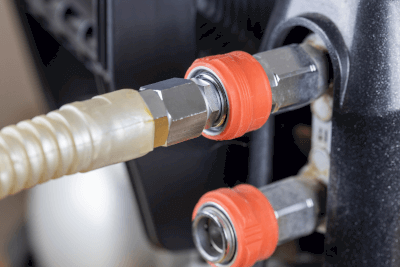

One-touch fittings allow for quick and easy connections by simply inserting a tube or hose, eliminating the need for screw connections or special tools. These fittings lock automatically upon insertion, providing a secure and leak-resistant connection. Selecting the right material for the fitting is crucial to ensure compatibility with the fluid’s properties and the operational temperature and pressure.

Uses of One-Touch Fittings

One-touch fittings find applications across various fields, including industry for connecting production lines, agriculture for irrigation and nutrient supply, and residential water supply systems for plumbing connections. Their convenience and efficiency enhance operations and maintenance across these areas.

Principle of One-Touch Fittings

These fittings incorporate a seal, a push-in mechanism for automatic locking, and a release mechanism for easy disconnection. The internal seal prevents leakage, while the spring-loaded push-in mechanism secures the piping in place. The release mechanism allows for quick removal of the piping, facilitating maintenance and adjustments.

How to Select One-Touch Fittings

Selection criteria include material compatibility, connection screw type, fitting shape, and maximum pressure rating. Stainless steel, corrosion-resistant SUS304, brass with nickel plating, and various resins are common materials. Fitting shapes like elbows, tees, and straights cater to specific spatial and functional requirements while matching the fitting to the system’s pressure requirements ensures safety and reliability.