What Is a Worm Wheel?

A worm wheel is a gear that makes up a worm gear.

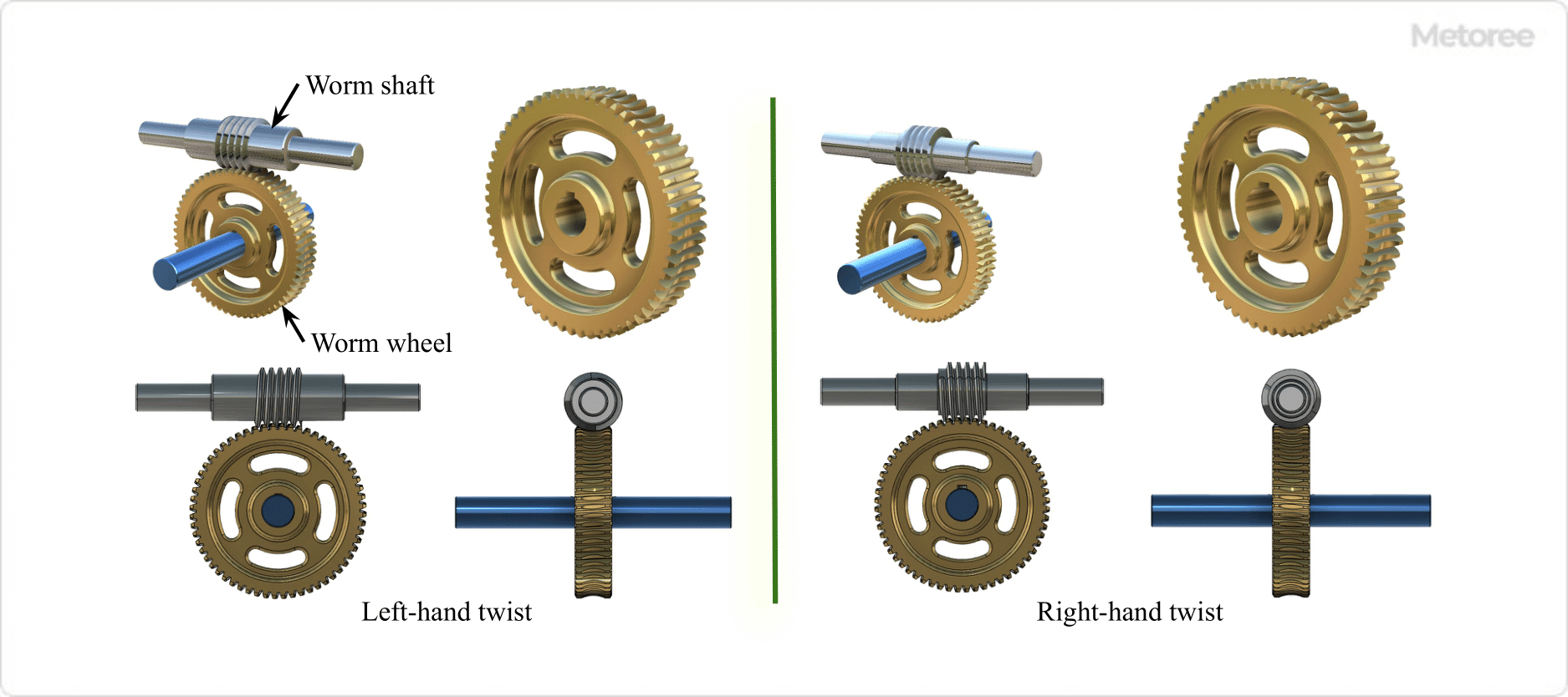

A worm gear is a type of screw gear. It is a combination of a worm (worm shaft), which is a threaded toothed shaft, and a Worm Wheel, which is a helical gear with its axis of rotation at 90 degrees to the worm’s axis.

Rotation of the worm feeds and rotates the teeth of the worm wheel that engage the worm.

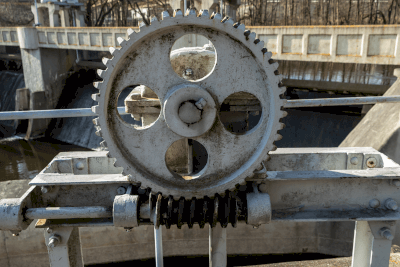

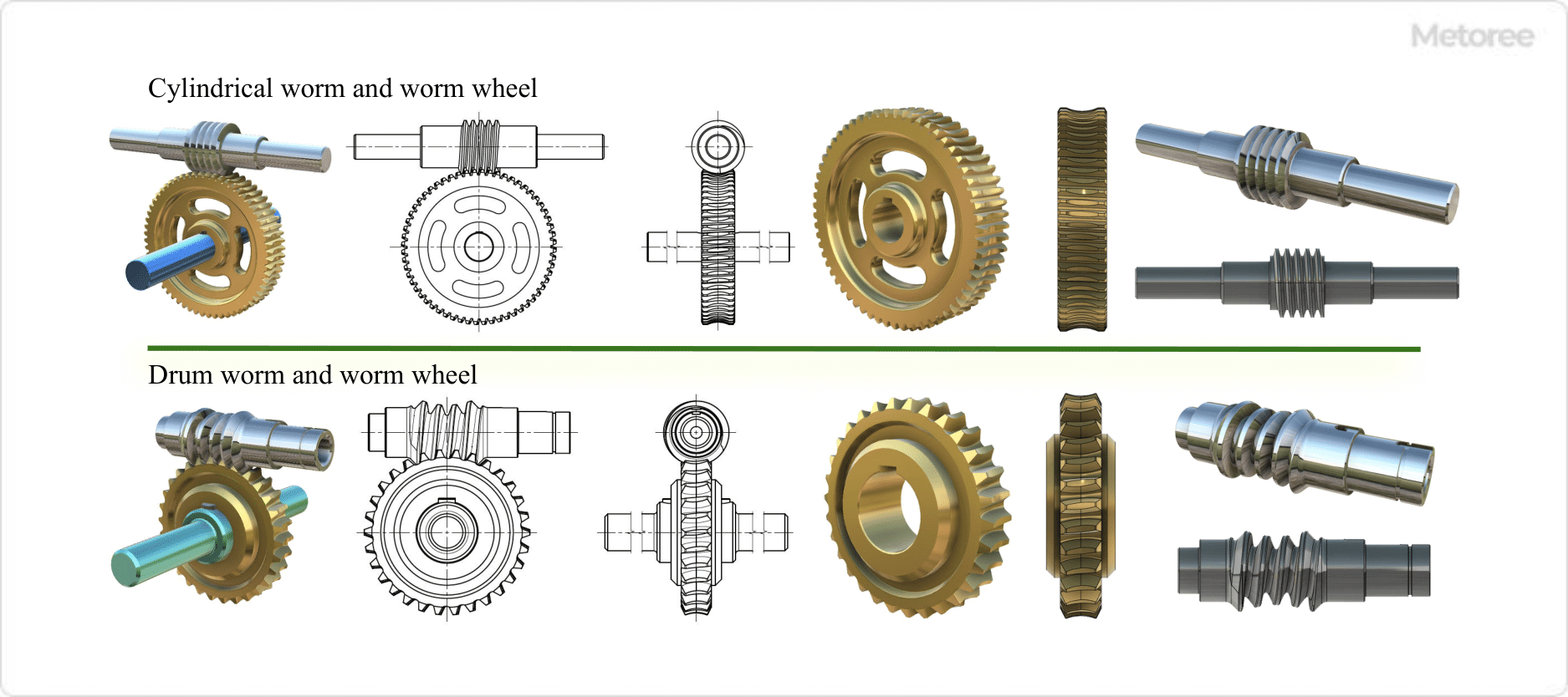

Figure 1. Structure of worm gear

Uses of Worm Wheels

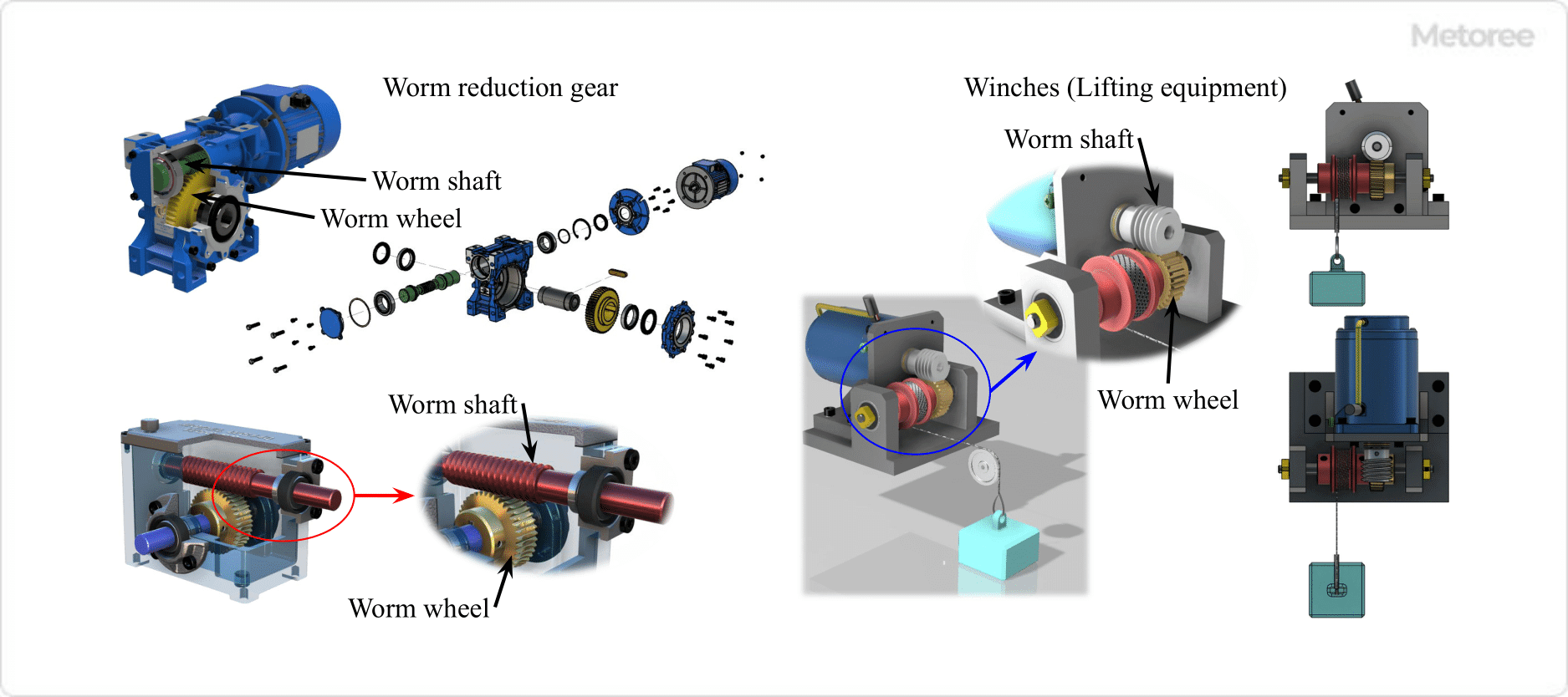

Figure 2. Example of worm gear (worm wheel) use

Worm wheels are used in combination with worms (worm shafts) as worm gears.

Worm gears are orthogonal shafts that can transmit power by changing the direction of the input and output rotary axes by 90 degrees, and can produce large reduction ratios, even with small gears. This includes devices, such as belt conveyors in factory equipment, screw jacks, steering systems for automobile steering wheels, wiper drives, and swiveling mechanisms for electric fans. It also includes material feeders in food and drug manufacturing equipment, music boxes, and stringed instrument pegs.

1. Machine Tools

Worm wheels are used in machine tools such as lathes and milling machines.

2. Conveyor

High torque for moving heavy loads and smooth belt movement.

3. Elevators

Used in hoisting devices for elevator carriages. It can provide the power needed to lift and lower heavy loads and smooth operation.

4. Automotive Steering Systems

Worm wheels are used in power steering systems in cars, trucks and other vehicles. Worm gears are used in some reduction gears for power steering drives.

5. Winches (Lifting Devices)

Worm gears are used in some winches. They output high torque and can lift heavy loads.

Principle of Worm Wheels

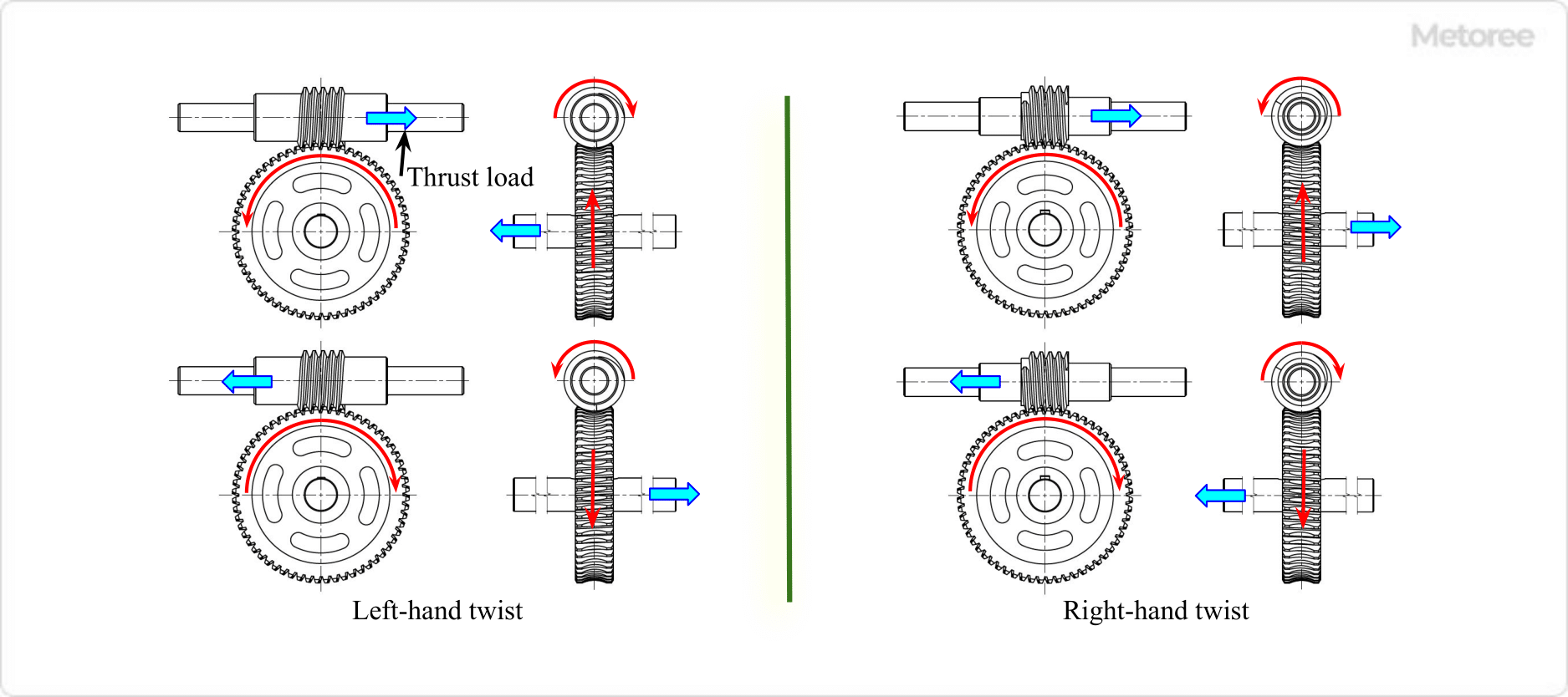

Figure 3. Direction of rotation and torsion of worm gear, direction of thrust load

Worm wheels are helical gears that fit into a helical groove machined into the worm (worm shaft). This is called a helical gear, and is one of the cylindrical gears with a spiral tooth trace.

The obliquely cut grooves mesh with the shape of the gears, resulting in a large amount of slippage and friction when the gears mesh with each other. Also, when rotating at high speeds, the tooth flanks become hot due to frictional heat. Therefore, it is necessary to reduce the coefficient of friction by using different materials, such as a hard metal for the worm and soft metal for the worm wheel.

In worm gears, when the worm is rotated, the worm’s spiral groove rotates. The teeth of the worm then press against the beveled teeth of the worm wheel, which transmit rotation to the worm wheel, causing it to rotate.

The worm gear can rotate in both directions (e.g., clockwise and counterclockwise when viewed from the input shaft side). This can be achieved by selecting the worm twist direction as a left-hand or a right hand twist. As the worm gear rotates, a thrust load is applied in the direction of the Worm Wheel and the center of the worm shaft. Therefore, the direction of the thrust load on the worm gear varies depending on the direction of rotation of the input shaft and the direction of the worm twist.

Types of Worm Wheels

1. Classification of Worm Gears by Shape

Figure 4. Shape of worm gear

Worm gears are classified into the above types according to the shape of the worm and worm wheel.

Cylindrical Worm and Worm Wheel

Used in most cases, tooth flanks are in linear contact with each other, and transmission capability is medium.

Drum-Shaped Worms and Worm Wheels

They have a special shape that requires a high degree of manufacturing precision, and their tooth flanks are in contact with each other, resulting in a high transmission capacity.

2. Number of Worm Gear Teeth

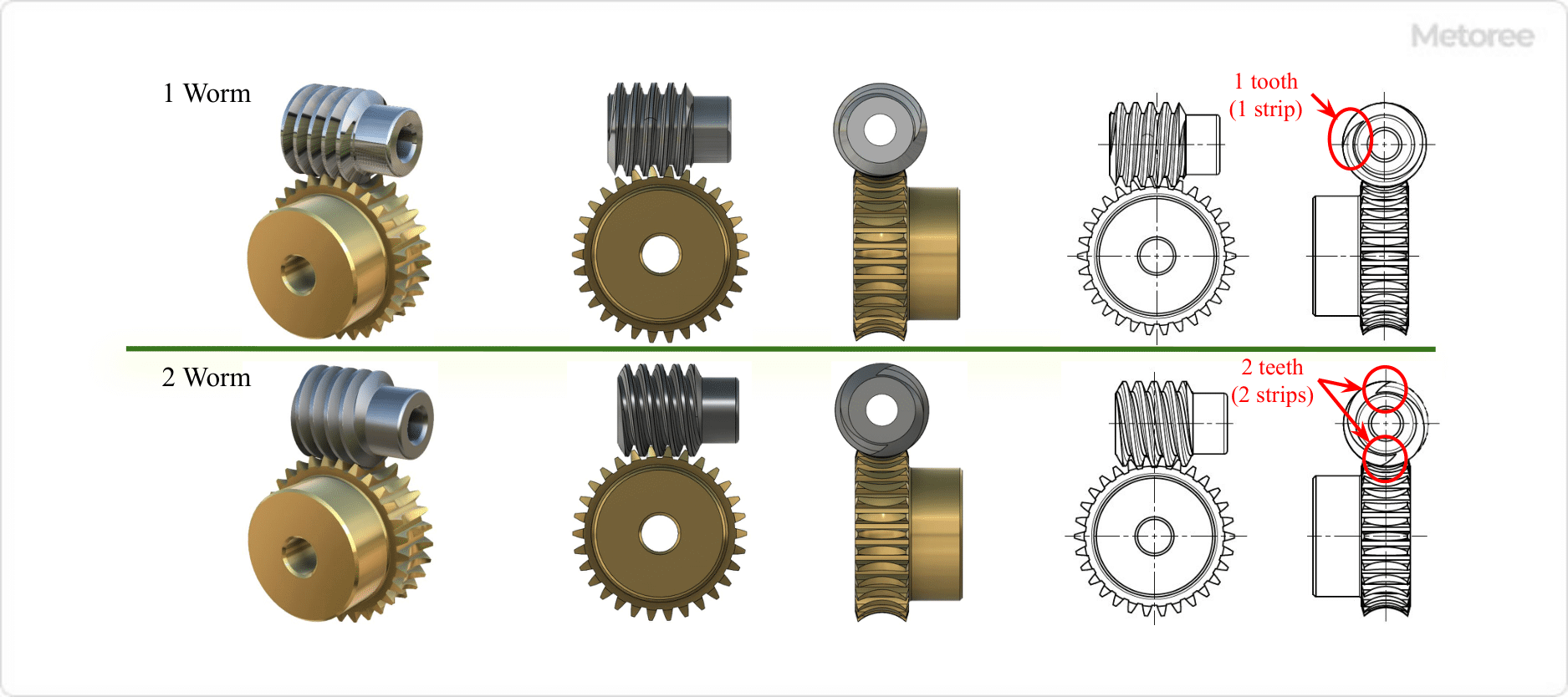

Figure 5. 1- and 2-strip worm gear

The number of worm gear teeth indicates the number of teeth on the worm (worm shaft), which can be confirmed by looking at the worm end face and checking the number of teeth per circumference of the shaft.

The number of worm teeth and their characteristics are as follows:

Single-Start

The worm has one tooth, and the worm wheel has the same number of teeth. The worm wheel rotates by one tooth per worm revolution. Reduction ratio is relatively low and torque transmission is stable.

Multi-Start

The worm has multiple teeth, and the worm wheel has the same number of teeth. The worm wheel rotates two teeth per worm revolution. The reduction ratio is greater than that of a single worm, allowing for greater torque transmission, but reducing the possibility of self-locking.