What Is a Motor Wrench?

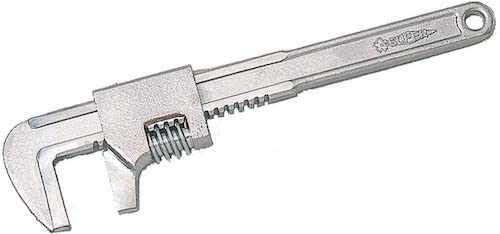

Motor wrenches are industrial tools designed for tightening nuts and fittings on sanitary fixtures with minimal effort. Unlike monkey wrenches, which have a perpendicular clamping part to the handle, motor wrenches have a parallel grip, allowing for a wider opening to accommodate larger nuts commonly found in plumbing.

And unlike pipe wrenches, which are intended for tightening cylindrical pipes and have jagged jaws that could damage nuts, motor wrenches provide a secure fit without damaging the nut’s surface, making them ideal for use with plumbing fixtures.

Uses of Motor Wrenches

Motor wrenches are versatile tools used in maintenance tasks for water pipes in sinks, toilets, and bathrooms, where they handle a wide range of nut sizes. Their design is particularly suited for fittings that require low tightening torque, making them compatible with nuts made of softer materials like resin.

Principle of Motor Wrenches

The defining feature of motor wrenches is the worm gear mechanism that allows for adjustable jaw opening widths, accommodating various nut sizes. Typically made from softer metals like aluminum to prevent damage to plated, brass, or resin nuts, these wrenches can adjust the opening width in a direction parallel to the handle. However, larger openings require more force for tightening or removal, hence the option to use a vertical motor wrench in tight spaces.

Other Information on Motor Wrenches

Precautions for Using Motor Wrenches

While motor wrenches are straightforward to use, certain precautions are necessary to avoid accidents or damage to nuts.

Ensure a Secure Grip

Before applying force, ensure the wrench securely grips the nut without rattling to prevent slippage that could lead to accidents or injuries. Additionally, avoid applying force if the grip is insufficient, as this could damage the nut.

Turn in the Correct Direction

Always turn the wrench from the upper jaw towards the lower jaw. When loosening nuts, be mindful not to apply excessive force in the wrong direction, as this could damage the wrench or the nut. For stuck nuts requiring more force, a vertical motor wrench is recommended over extending the handle, which could lead to breakage.