What Is a Precision Screwdriver?

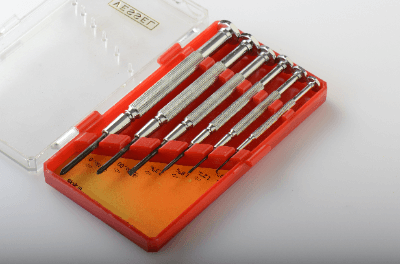

Precision screwdrivers are specialized tools used for tightening small screws. These screwdrivers come in various types, including the commonly known Phillips and flathead versions. There are also less common types with Y-shaped or star-shaped tips.

Precision screwdrivers are specialized tools used for tightening small screws. These screwdrivers come in various types, including the commonly known Phillips and flathead versions. There are also less common types with Y-shaped or star-shaped tips.

Precision screwdrivers are commonly used for tasks such as replacing batteries in electronic devices. While affordable sets are available in stores like 100 yen shops, for professional use, it’s recommended to choose higher-quality products for ease of use.

Uses of Precision Screwdrivers

Precision screwdrivers are often employed in precision equipment to tighten small screws. Small screws, which are used to fasten the enclosures of precision equipment and secure printed circuit boards inside the devices, necessitate the use of these specialized tools.

Aside from precision instruments, they are also used for devices like cameras and eyeglasses.

Principle of Precision Screwdrivers

The operating principle of a precision screwdriver is the same as that of a standard screwdriver. It is used to turn screws with a cross-shaped or flat-shaped groove on the head by fitting the appropriate tip shape of the screwdriver.

Since screws for precision screwdrivers are typically not designed for high axial force, the handles of these screwdrivers are thin, making it difficult to generate excessive tightening torque.

Other Information on Precision Screwdrivers

1. Material of Precision Screwdrivers

The tips of precision screwdrivers and other screwdrivers are commonly made of tool steel like S2 steel or chrome-vanadium-molybdenum steel (CVM tool steel). These materials are heat-treated for hardness and wear resistance, ensuring longevity, and many are coated for additional durability.

Since precision screwdrivers are used for relatively small loads compared to general-sized screwdrivers, considerations such as insulation and magnetism (“Does the screw stick to the magnetic tip?”) are important when selecting a screwdriver.

2. Sizes of Precision Screwdrivers

Precision screwdrivers come in various sizes to accommodate small screws. For crosshead screws, sizes are indicated by numbers like No.000, No.00, and No.0. Flathead screw sizes are denoted by the width of the groove, requiring careful selection to match the screw size.

3. Types of Crosshead Screws

There are several types of crosshead screws, including:

- Phillips Type: The most common type, named after its inventor.

- Posi-Drive Type: Commonly used in Europe.

- For Precision Instruments: Originally a standard in the Japanese camera industry, known as the S-shape.