What Is a Slide Shaft?

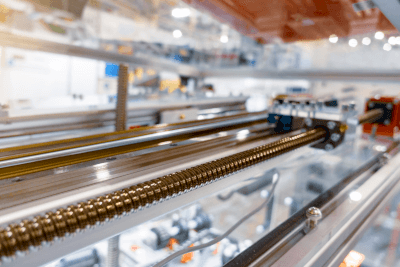

A slide shaft is a component used to guide either linear or vertical motion of equipment.

Since bearings (slide ball bearings, metal bearings, plastic bearings, etc.) are mounted on the shaft, the shaft itself serves as the inner ring of the bearing. Due to their installation on parts subject to repeated motion, they exhibit excellent wear resistance. They are often used in combination with other parts and must meet stringent geometric tolerance standards such as cylindricity and roundness.

Uses of Slide Shafts

Slide shafts find applications in a wide range of fields, including piston rods for hydraulic and pneumatic cylinders, hydraulic and pneumatic equipment, construction machinery, molding machines, special vehicles, and various factory automation equipment. They serve as critical components in various industrial machines and robots.

Choice of shaft material, plating type (non-tempered high-strength steel plated, stainless steel plated, etc.), plating hardness, outside diameter tolerance, surface roughness, and curvature depend on the intended use.

Other Information on Slide Shafts

1. Slide Shaft Features

- Excellent Wear Resistance:

A uniform and even hardening layer reduces wear. - Special Specifications:

Machining according to drawings, heat treatment, and special surface treatments are available using materials such as SCM and SKS materials. - Surface Roughness:

Precision grinding can be applied. - Wide Variety of Shapes:

Various shapes are available, including straight shapes and pipe shapes that are lightweight and can utilize hollow parts.

2. Slide Shaft Processing Types

- Straight

- Female and male thread machining

- Step processing

- Step female thread

- Ring groove machining

- Step grooving

- Plate grooving

- V Grooving

- Coaxial Male Thread

- Hexagonal Hole

- Double Hole Tapping

- Male thread relief machining

- Tapping on the bus bar

- Spanner additional machining

- Additional flat grinding

- Key Groove Machining