What Is a Rotary Evaporator?

A rotary evaporator is a type of vacuum distillation device. Solvents can be efficiently removed by rotating a sample solution under reduced pressure. Because they are easy to operate and can be used to remove a wide range of solvents, they are widely used in laboratories at universities and other research institutions, as well as in R&D departments at private companies.

On the other hand, depending on the heating temperature of the sample solution and the degree of depressurization, there is a risk that the sample solution may boil suddenly, or that the weight of the sample solution may break the glass of the connection part.

Uses of Rotary Evaporators

Rotary evaporators are a type of reduced-pressure distillation equipment. They are frequently used in laboratories conducting synthesis experiments because they can evaporate solvents with high boiling points by increasing the degree of depressurization and heating temperature.

Since distillation using rotary evaporators is one of the basic operations in synthetic experiments, it is often used not only in university laboratories but also in undergraduate chemistry experiments. Others are routinely used in the research and development departments of various private companies, including chemical, polymer, and textile manufacturers.

Structure and Mechanism of Rotary Evaporators

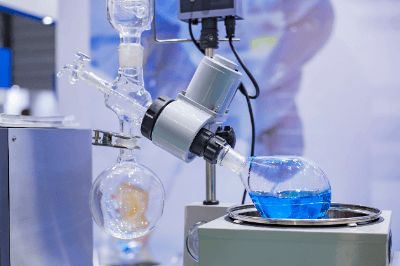

Rotary evaporators consist of a water bath (or oil bath) for heating the sample, a cooling water circulator, a decompression pump, and a flask for collecting the solvent condensed in the device. When using rotary evaporators, depressurization is started by attaching an eggplant flask containing the sample solution to the device and rotating it, followed by heating the flask in a water bath heated to a predetermined temperature. Under reduced pressure conditions, the boiling point of the solvent is lowered, so the solvent vaporizes at a lower temperature than under atmospheric conditions. In addition, by rotating the flask containing the sample solution, a thin film is created inside the flask, i.e., the surface area is increased, allowing the solvent to vaporize more efficiently.

A cooling water circulation system is installed between the sample solution-filled Nas flask and the decompression pump, and the evaporated solvent vapor is cooled, condensed, liquefied, and collected in a solvent collection flask installed below the cooling water circulation system. The sample solution is continuously rotated, and when the solution is reduced to a certain volume, the device is stopped to release the depressurization and collect the sample.

Cautions When Using Rotary Evaporators

Rotary evaporators are very convenient devices, but there are a few points to remember when using them.

The first is to be careful of the sample solution boiling out. As mentioned above, rotary evaporators vaporize the sample under reduced pressure, so if the solvent has a low boiling point, the solution may boil rapidly and reach the inside of the device, resulting in contamination of the device and possible loss of sample. To prevent sudden boiling, it is recommended to use a low-boiling solvent in a smaller volume or to reduce the pressure at room temperature without heating in a water bath, while observing the liquid level at first.

Second, be careful not to damage the apparatus. When attaching a flask containing sample solution to the apparatus, a large load is applied to the neck of the flask. Therefore, flasks with small scratches or cloudy white may break at the neck when installed, leading to unexpected accidents. To prevent such accidents, it is necessary to visually check for flaws before attaching the flask to the rotary evaporators and to reduce the load itself by decreasing the amount of sample solution.

Cleaning the Rotary Evaporators

The rotary evaporators may be cleaned when the degree of depressurization has decreased after prolonged use or when the inside of the device has become contaminated due to sudden boiling. The equipment can be disassembled at the joints. However, large glass parts such as the cooling water circulation section are heavy and easily breakable, so it is recommended that two or more people work together wearing non-slip gloves during disassembly. After disassembling the evaporator, each part should be cleaned or replaced. If the vacuum is low, it is also necessary to replace or grease the vacuum seals. In some cases, when handling samples for which contamination is to be avoided, grease may not be applied.