What Is a Rotary Connector?

Rotary connectors facilitate electrical connections between rotating and stationary components. They are crucial for powering rotating parts or transmitting signals and data from sensors on rotating parts to stationary control units.

Commonly, rotary connectors contain liquid metal, such as mercury or gallium alloys, to maintain conductivity. They find application across diverse fields including industrial machinery, automotive, medical equipment, and telecommunications, significantly contributing to technological advancements.

Applications of Rotary Connectors

Rotary connectors bridge rotating and stationary parts, which is crucial for devices with electronic components on rotating sections. They eliminate the risks associated with cable connections, such as disconnection or short-circuiting, by considering contact friction and electrical characteristics in their design. In the industrial machinery sector, they are integral to automated processes, featuring rotating machines like machine tools and robots.

1. Automotive Industry

In the evolving automotive sector, rotary connectors are vital for the transmission of signals and power among numerous electronic control devices. They support the seamless integration of functions such as entertainment systems, sensors, and airbags.

2. Medical Equipment Field

The demand for rotary connectors in medical technology is high, especially in surgical robots and diagnostic equipment, enabling precise operations and data gathering through rotational signal transmission.

3. Communication Equipment Field

Telecommunications equipment, including antennas and satellite communication devices, rely on rotary connectors for stable signal transmission during rotation, ensuring signal quality and communication reliability.

Principle of Rotary Connectors

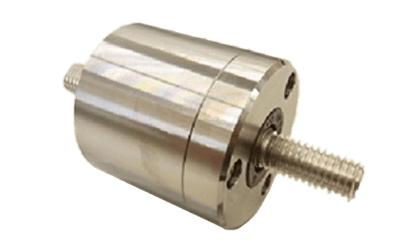

Rotary connectors, essential in rotational machinery, consist of a stationary part (stator) and a rotating part (rotor). The stator connects to a base or frame, while the rotor connects to another component, facilitating uninterrupted signal and power transmission through contact between them. Material durability, electrical characteristics, and design considerations like dust and waterproofing are critical for their performance.

Types of Rotary Connectors

Variety in design and function leads to different rotary connectors, each suited to specific applications and requirements.

1. High Frequency Rotary Connectors

These are ideal for wireless and telecommunication equipment, designed for efficient high-frequency signal transmission.

2. High Current Rotary Connectors

Crucial in industrial machinery and power generation, these connectors are designed for high durability and reliability, facilitating efficient high-power supply.

3. Fiber Optic Rotary Connectors

Designed for optical signal transmission through optical fibers, these connectors are key in high-speed, high-bandwidth data communications.