What Is a CV Cable?

A CV cable, officially known as a “cross-linked polyethylene insulated vinyl sheath cable,” is commonly used in industrial power transmission. It employs cross-linked polyethylene for insulation and vinyl for the sheath layer.

A CV cable, officially known as a “cross-linked polyethylene insulated vinyl sheath cable,” is commonly used in industrial power transmission. It employs cross-linked polyethylene for insulation and vinyl for the sheath layer.

Uses of CV Cables

Primarily, CV cables facilitate power transmission. In urban areas, these cables are often seen suspended from utility poles as supports. Distinguished by their core wire covered with vinyl sheath or polyethylene, CV cables are designed to withstand outdoor elements like wind, rain, and sunlight. Unlike vinyl-sheathed cables used in household power distribution, CV cables are not typically found inside homes.

Principle of CV Cables

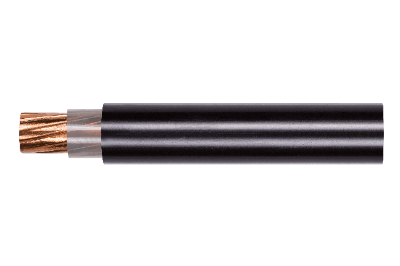

High-voltage CV cables typically consist of multiple layers: a core wire (usually copper or aluminum), a semiconducting layer, cross-linked polyethylene insulation, a copper tape layer, and a vinyl sheath. The core wire acts as the electrical pathway, often composed of twisted thin copper wires for flexibility.

The semi-conductive layer, made from carbon-rich polymers, surrounds the core wire, preventing voltage-related deterioration of the cross-linked polyethylene insulation. An additional semi-conductive layer is placed outside the insulation, leading up to the copper tape layer. This layer, a thin copper film, contains electromagnetic emissions from the core wire and acts as a grounding pathway in case of insulation failure. The outermost vinyl sheath, usually black, offers corrosion protection and improved weather resistance.

In multi-core cables, insulating fibers like jute are used as inclusions between the sheath and copper tape layer to fill gaps. These cables, often three-core for compatibility with 3-phase power transmission systems, may utilize a triplex construction for enhanced heat dissipation and are also referred to as CVT cables.

Other Information on CV Cables

Differences in CV Cables According to Voltage

The structure of CV cables varies depending on the voltage requirements:

1. CV Cables for Special High Voltage:

At special high voltage levels, the cross-linked polyethylene insulation is made thicker, and the copper tape layer is designed more like a flexible tube or wire rather than a tape, enhancing insulation and grounding capabilities.

2. 3.3KV CV Cables:

For 3.3kV applications, a semiconducting layer is replaced by an insulating material like PET. These cables use a single copper tape layer for grounding and have simpler end treatments compared to 6.6kV cables.

3. Low-Voltage CV Cables:

Low-voltage cables often omit the semi-conductive and copper tape layers due to lower electromagnetic emissions. The cross-linked polyethylene insulation is also thinner than that in high-voltage cables.