What Is a Magnetorheological Fluid?

Magnetorheological fluid, coated with a surfactant 2 to 3 nm thick, is stably dispersed in mediums such as oil or water.

It consists of magnetic fine particles, such as magnetite, blending ferromagnetism of magnetic materials with the fluidity of liquids. This fluid can alter its viscosity and shape under the influence of a magnetic field, provided by a permanent magnet or similar means, exhibiting fluidity with changing magnetic fields. In a magnetic field, its apparent viscosity and specific gravity vary with the field’s strength.

Uses of Magnetorheological Fluids

Magnetorheological fluids are primarily used in magnetic fluid seals, including dust seals in HDDs to prevent static electricity and vacuum seals in semiconductor manufacturing equipment. They are also utilized in speakers and dampers, increasingly in automobile shock absorbers, and as contrast media for cancer diagnosis in the medical field.

Principle of Magnetorheological Fluids

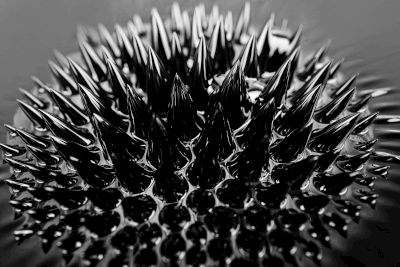

The magnetorheological fluid contains magnetite, acting magnetically only within a magnetic field. Outside a magnetic field, it behaves as a regular fluid but can align like a magnet when exposed to one. Magnetic particles align along the magnetic force lines between the N and S poles, displaying a spiking phenomenon due to the interplay of the orienting force and the fluid’s interfacial tension.

Magnetite particles are oxidized to non-magnetic hematite upon air exposure, necessitating a protective surfactant coating to maintain their magnetorheological properties.

Types of Magnetorheological Fluids

Magnetorheological fluids vary by solvent type, including hydrocarbon oil-based, water-based, and fluorinated oil-based fluids. Key to their formulation is the selection of a compatible surfactant with the base fluid, essential for the intended application.

These fluids can be produced through methods like coagulation, pyrolysis, physical vapor deposition (PVD), laser evaporation, chemical vapor deposition, and continuous vacuum deposition on an active liquid surface, with the latter involving surfactants and oil on a rotating vacuum drum and metal heated to around 2,000°C to form fine particles.

Structure of Magnetorheological Fluids

As a magnetic colloidal solution, the magnetorheological fluid comprises ferromagnetic particles (e.g., manganese zinc ferrite or magnetite), a surfactant layer, and a base liquid like water or oil. The ferromagnetic particles, approximately 10 nm in diameter, achieve a stable dispersion through the interaction with the surfactant and base liquid.

The optimal particle diameter is around 9 nm, with a surfactant molecular length of 1.5 nm, balancing the need to prevent agglomeration and ensure sufficient magnetism by optimizing the metallic magnetic material’s concentration in the fluid.