What Is a Lathe?

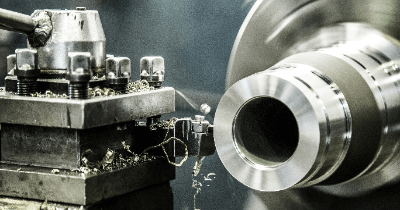

A Lathe is a type of machine tool for metalworking. It is a machine that fixes the material to be processed on a rotating base called a chuck, and applies a cutting tool called a bite to the workpiece to cut it into the desired shape.

A Lathe is a type of machine tool for metalworking. It is a machine that fixes the material to be processed on a rotating base called a chuck, and applies a cutting tool called a bite to the workpiece to cut it into the desired shape.

A lathe consists of a spindle stand, a bed, a tailstock, a feeder, and a reciprocating stand, etc. By changing the type of byte, various types of processing can be performed with one machine, such as external turning, internal diameter processing, end face grinding, taper grinding, thread cutting, and butt cutting.

Since the lathe processes materials while rotating them, it is often used for processing circular materials.

Uses of Lathe

Lathes are often used for processing circular or conical shapes because they process materials while rotating them.

Specifically, they are often used for round industrial products such as screws, bolts, and shafts, but they are also widely used for everyday items such as doorknobs and chair parts.

The widespread use of NC lathes, which numerically control everything from blade change to feed rate and coordinate position, has made it possible to mass-produce high-quality parts, making them indispensable in the production of mass-produced parts.

Principle of Lathes

A lathe is basically composed of five parts.

1. Spindle Head

The spindle base incorporates the motor and transmission used to rotate the material and is responsible for controlling the number of revolutions and direction of rotation. The unit of rotation speed is RPM, which indicates how many revolutions the spindle makes per minute.

2. Bed

The bed is a wide table-like area that supports the lathe’s tailstock and reciprocating table. When the tailstock is moved, it slides on the bed. Since the metal rails on the bed are in contact with the sliding surfaces of the tailstock, it is a good idea to clean the chips on the bed periodically to prevent the rails from being scratched.

3. Reciprocating Table

The reciprocating table is used to move the cutting tool attached to the tool rest back and forth, left and right. Care must be taken when operating the reciprocating table, as too close to the rotating chuck can cause contact between the tool rest and chuck, resulting in an accident.

4. Feeder

Like the reciprocating table, this device is used to move the cutter back and forth, left and right, but it is more precise than the reciprocating table, allowing operation in increments of 0.01 mm.

5. Centering Table

The table on the bed attached to the opposite side of the spindle base is the tailstock. It is mainly used to support and secure a long workpiece from the opposite side, or to drill a hole with a drill attached.

How to use a Lathe

First, the appropriate cutting tool is selected according to the size, material, shape, and processing details of the workpiece, and the cutting speed, spindle speed, and other processing conditions are determined.

Next, the workpiece is fixed in the chuck, and the tool is fixed to the tool rest by adjusting the height of the cutting edge so that it matches the center height.

After shaving the end face of the workpiece, set the center drill on the tailstock and bring it close to the workpiece, set the drill in the center of the workpiece to set the machining standard, and then lathe the workpiece according to the drawing.

How to Select a Lathe

When selecting a lathe, the following specifications should be checked:

1. Distance Between Centers

This is the distance from the spindle to the headstock and represents the maximum length of the workpiece. In actual lathe turning, a chuck is attached to the spindle to set the workpiece. In addition, a drill, etc., is also mounted on the headstock, so only materials shorter than the center-to-center distance can be machined.

The actual machining range is about 60-70% of the center-to-center distance.

In the case of internal diameter machining, the tool set in the tool rest on the reciprocating table is used to cut the inside of the workpiece, so the reciprocating table interferes with the workpiece, further reducing the length of material that can be machined.

2. Up Swing of the Bed

The distance from the bed to the spindle multiplied by 2 represents the maximum diameter of cylindrical material that can be machined without touching the bed.

In practice, the diameter of the material that can be machined is limited by the diameter of the chuck, since the workpiece is fixed using a chuck attached to the spindle.

For the center-to-center distance and swing over the bed, select a size that allows for the size of the material to be machined. However, a lathe is not a machine that can be easily replaced once purchased and installed. When selecting a lathe, it is necessary to consider the installation space and price.