What Is an Abrasion Testing Service?

An abrasion testing service is a test to evaluate whether burning occurs, how wear progresses, the amount of wear, etc. Using test specimens in order to understand the wear phenomenon that occurs in various industrial products.

In the friction test, a test specimen, such as a pin or ball is continuously moved under a constant load and at a constant speed. The frictional force generated and the amount of friction after a specified period are then evaluated. In industrial products, there are many areas where parts rub against each other. If seizure occurs in such parts, the parts stick to each other and the amount of wear increases, preventing the parts from functioning properly, so countermeasures are necessary.

In addition, the amount of wear varies depending on the conditions, even when the same parts are used in combination with each other. Therefore, abrasion testing services that can reproduce the conditions under which various types of friction occur are conducted to measure the frictional force and the amount of friction.

Uses of Abrasion Testing Services

Friction testing is used in the development process of various industrial products. The durability of a product is mainly related to how long it can be used in areas where metal parts come into contact with each other and rub against each other. Friction testing is an important evaluation method to confirm the ability of a product to maintain its required functionality over the targeted period of use.

Friction testing is also used to investigate the causes of defects in the marketplace. Wear phenomena are very complex and must take into account the effects of temperature, load, load variation, and even the presence of lubricants, even when the materials are the same.

When unexpected wear occurs in the market, abrasion testing services may be performed under various conditions to investigate the factors that accelerate wear.

Principles of Abrasion Testing Services

In most abrasion testing services, two specimens are brought into contact with each other while a load is applied and is subjected to relative motion to check for seizure or to measure the amount of wear over time. Industrial standards are determined by the shape of the test specimen and other factors depending on the test method.

As mentioned above, wear phenomena are complex, so the effects of temperature, humidity, the presence or absence of lubricant, the type of lubricant, and the amount of lubrication must also be considered. It is necessary to consider test conditions other than the test specimen so that the product can be evaluated in the environment required for the product.

Types of Abrasion Testing Services

Abrasion testing services are specified in JIS and other industrial standards. There are five typical test methods as follows:

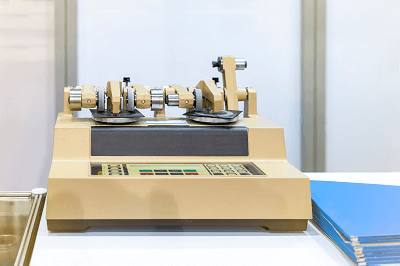

1. Pin-On-Disk Type / Ball-On-Disk Type

A pin (hole) is pressed against a fixed disk-shaped specimen, which is then subjected to a rotating or horizontal reciprocating motion to measure the coefficient of friction and the amount of abrasion testing services. In the ball-on-disk method, the test starts with point contact, so it is easy to get good contact between the specimens. The contact area increases as the ball abrasion testing services, and the surface pressure of the contact surface decreases even if the load during the test is the same.

2. Ring-On-Disk Type / Thrust Cylinder Type

A hollow cylindrical specimen is pressed against a flat plate specimen and rotated to measure the amount of wear. Unlike in the ball-on-disk method described above, the surface pressure does not change with the progress of the test.

3. Block-On-Ring Method

A block-shaped test piece is pressed against the side of a hollow cylindrical test piece and rotated to measure the amount of friction and coefficient of kinetic friction. At the start of the test, the specimens are in linear contact with each other, but as abrasion testing services progress, the contact area increases and the contact surface pressure decreases.

4. Four-Ball Type / Sone Type / Shell Type

Four spheres of the same size are piled up in a pyramid shape, and the top sphere is rotated while being pressed against the rotating sphere to measure the wear scar diameter. This method is mainly used to evaluate seizure characteristics under lubrication conditions. The Sone-type test uses a 3/4-inch steel ball, while the Shell-type uses a 1/2-inch steel ball.

5. Pin and Block Type

A rod-shaped specimen is sandwiched between blocks on both sides and the rod is rotated to measure the abrasion testing services. It is mainly used to evaluate seizure characteristics under lubrication conditions.