What Is a Plastic Engineering Compound?

A plastic engineering compound is an engineering compound, which is a plastic with higher performance than the plastics used in everyday products.

When plastics were first developed, industrial equipment, production parts, and tools required a certain level of strength and heat resistance, which was difficult to achieve with plastics, so metals were used.

However, during the period of rapid economic growth, there was a growing demand for lightweight materials that could be easily processed, and plastic engineering compound with various functions were developed.

Uses of Plastic Engineering Compounds

Plastic engineering compounds are still very much in use today as product materials in various industries.

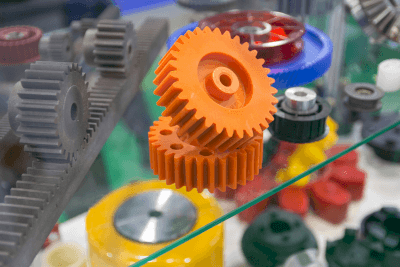

In the automotive industry, its applications include headlights, internal plastic parts, cylinders, gears, and connectors. They are also used in machinery, fans, impellers, and hydraulic tubes; and in the electrical industry, various cables, covering materials, sockets, and rotary switch parts.

The common point is that they are used in parts subject to severe wear and tear and are required to have various types of strength and heat resistance more than ordinary plastics.

Characteristics of Plastic Engineering Compounds

Plastic engineering compounds are characterized by higher strength and heat resistance than ordinary plastics.

Although there is no definition of what features plastic engineering compounds must exhibit, it must meet the following criteria: tensile strength of 40 MPa or higher and resistance to heat of 100°C or higher.

However, there is a standard that it can withstand a tensile strength of 40 MPa or higher and heat of 100°C or higher.

Plastic engineering compounds include polycarbonate, polyamide, polyacetal, and polybutylene terephthalate.

Super plastic engineering compounds, commonly known as super engineering compounds, are plastics that are stronger and more heat resistant than plastic engineering compounds.

Super plastic engineering compounds, commonly called “super plastic engineering compounds,” have a higher strength and higher heat resistance than plastic engineering compounds.

Like plastic engineering compounds, there is no clear definition, but they are generally defined as plastics with a heat resistance temperature of 150°C or higher.

Because of its increased strength and heat resistance, it is applied to parts that are subject to more intense wear and tear.

It is often used as a material for parts that accumulate damage on a daily basis, such as the inside of equipment, rather than for parts that are visible from the outside.

There are many types of plastic engineering compounds, and each has its advantages and disadvantages. However, they are all characterized by their high cost, so it is not necessary to use plastic engineering compounds when designing a product.

It is necessary to consider whether the product needs to be strong enough to use plastic engineering compounds when designing the product.