What Is a Pulley?

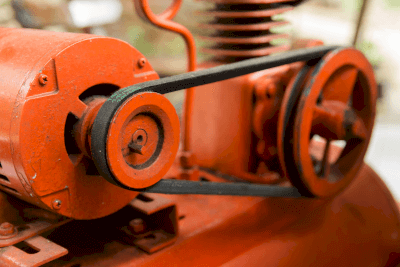

Pulleys are mechanical parts that transmit rotational force from shaft to shaft via a belt. There are various shapes and types of pulleys. The belt and pulley are used in combination with other pulleys of the same type. There are pulleys for flat belts, V-belts, toothed pulleys, round belts, metal belts, etc., and there are belts that match each type of pulley. There are also a number of belts manufactured according to the manufacturer’s own specifications.

Uses of Pulleys

Flat belt pulleys have high transmission efficiency and are used for power transmission in agricultural machinery and for paper transport in office automation equipment.

Pulleys for V-belts are resistant to high loads and can be used to apply multiple belts side by side. They are used for power transmission in drilling machines, automobile engines, dust collectors, etc.

Toothed pulleys are used in places where slippage is not desired. They are used in equipment that performs high-precision and precise positioning and conveyance by servomotors and stepping motors, printer equipment, etc.

Pulleys for round belts are not suitable for high loads. However, they have a high degree of freedom and are used in toys, office automation equipment, etc.

Principle of Pulleys

As mentioned above, pulleys transmit rotational force in combination with belts. There are two methods of transmission: friction transmission and meshing transmission.

Pulleys for flat belts, V-belt pulleys, and round belt pulleys are friction motors, which transmit rotational force by the frictional force of the contact surface between the pulleys and the belt. The transmission force is greater than that of a flat belt pulley. Slip is inevitable in friction transmission, and it is used in situations where it is tolerated. However, in some cases, friction transmission is considered to work as a safety device, taking advantage of the fact that the pulleys and belts slip and spin when an excessive load is applied. For example, when something is caught in the drive system, slipping prevents overloading by preventing a certain amount of force from being applied.

Toothed pulleys are an engaged transmission. The pulleys and belts have teeth that engage with each other to transmit power, so slippage does not occur. Therefore, it is used in situations where high-precision positioning is required. Sprockets and chains are similar mechanical components, but toothed pulleys are lighter, quieter, and require less lubrication.