What Is a Busbar?

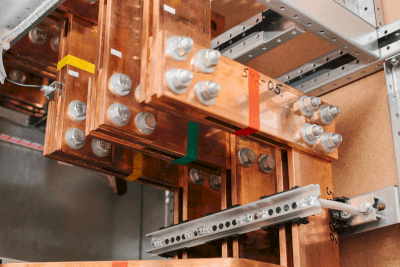

A busbar is a copper bar used in control panels and power receiving panels.

Busbars are described as “BUS” in electrical drawings, etc., and are used in control panels by being fixed to insulators, etc. Unlike cables, bus bars have low flexibility and are used in locations where dimensions are clearly defined in advance.

Busbars have a higher allowable current than cables because they do not use organic materials as sheathing, have a higher allowable temperature, use a larger amount of copper, and have a larger cross-sectional area.

Uses of Busbars

Busbars can be used in a wide range of situations in production plants.

For example, it is used as an alternative to the main trunk wiring in control panels for industrial equipment. Busbars have a high allowable current and can easily be tapped off to create branch wiring, making them excellent as main trunks. For the same reason, it can also be used as a wireway for power-receiving panels.

It is also used as a conduit in high-current equipment for electrolytic refining. It is stronger than cable, has no sheath, thus reducing the amount of material, and has a higher allowable current.

Principle of Busbars

The structure of a busbar is simple, consisting of bare copper plates laminated together. They are mainly made of copper to supply high currents with low loss. This is because copper has extremely high conductivity among metals and is relatively inexpensive and readily available. The main metal with higher conductivity than copper is silver, which improves conductivity by about 6%. However, silver is by far the most expensive metal compared to copper, costing about 100 times more by weight.

In addition, busbars do not have a sheath and are always in contact with the outside air, which allows them to dissipate heat very well. Therefore, copper bus bars are the best choice for supplying large currents.

Types of Busbars

Busbars are mainly made of copper and are also called copper bars.

1. Tough Pitch Copper

The most widely distributed type of copper bar, this material has a copper purity of 99.90% or higher and an oxygen content of 80 ppm. It has excellent ductility, electrical conductivity, and durability, and is used for electrical components such as switchboards and in the chemical industry.

2. Oxygen-Free Copper

A material with a copper purity of 99.96% or higher, with an oxygen content of 10 ppm or less. When used at high temperatures, hydrogen and oxygen react and hydrogen embrittlement is likely to occur. Hydrogen embrittlement is a phenomenon in which the toughness and ductility of a material decrease due to hydrogen absorbed in the material.

This material is used when brazing or welding is required or when it is subjected to high heat during processing or use. However, it has poor distributability and is expensive.

3. Aluminum

Copper is generally used for busbars, but aluminum is also used in addition to copper. Aluminum has lower tensile strength and conductivity than copper, and its conductor volume is larger. However, due to its lower price and lighter weight, aluminum busbars can be used to reduce costs and weight.

How to Choose Busbars

The advantages of using busbars are many.

1. Cross Sectional Area

Busbars are manufactured from metal in the form of thick plates. Since the cross-sectional area is larger than that of a conductor and the capacity is also larger, a large current can flow.

2. Heat Dissipation

Since there is no insulating film, heat dissipation is higher than that of conductors.

3. Ease of Installation

Exclusively designed bus bars can be installed as they are, and general-purpose bus bars can be installed with Y-shaped or round terminals without terminal treatment.

4. Branching

Fixed with bolts or screws, terminals can be stacked or crossed. Screw holes can be placed along the way for efficient branching.

5. Other Advantages

High-frequency currents generated by switching affect malfunctions and noise. Bus bars with a large surface area reduce the effects of high-frequency currents.

Easy installation due to dedicated design, eliminating the need for terminal processing. Inexpensive materials reduce the manufacturing cost of distribution boards and control panels.

Structure of Busbars

A busbar is fabricated through the following processes:

1. Drilling

A hole is drilled in the required location in the metal plate. If necessary, threads are made by tapping.

2. Bending

After drilling, bending is performed using a press or bender, and edge-wise bending or flat-wise bending is performed according to needs. Edge-wise bending is done in the width direction, while flat-wise bending is done in the thickness direction.