What Is a Cutting Tool?

A cutting tool is a tool used in the cutting process. Cutting is classified as a machining process called removal machining, in which the surface of a material, such as metal, wood, or plastic, is removed to create a desired shape. The tool is moved relative to the material to remove it. The material to be cut is called the work material.

Because cutting requires a large amount of force, in most cases cutting tool is mounted on a machine. When the amount of material to be cut is very small or soft materials are to be processed, the tool may be held by hand.

The parts that are removed and discarded are called chips or swarf.

Uses of Cutting Tools

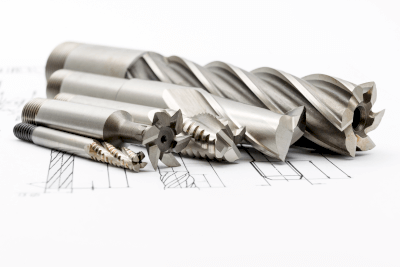

There are various types of cutting tools. Typical examples include bites used in lathe turning, cutters and end mills used in milling, hob cutters used to cut gears, drills used to make holes, and broaches used in broaching machines.

The removal rate per hour is higher compared to grinding with a regular wheel, enabling more efficient machining. On the other hand, grinding is superior in terms of dimensional accuracy and surface roughness, so when high-precision machining is required, it can be done by grinding after cutting.

Principle of Cutting Tools

Cutting tools are required to have high levels of hardness (wear resistance), heat resistance, and toughness (resistance to chipping) so that they will not be easily worn or damaged when cutting materials.

Typical materials for cutting tools include, in descending order of hardness, diamond, CBN (cubic boron nitride), cemented carbide, and HSS (high-speed tool steel). Hardness and toughness are inversely related, and the most suitable one is selected according to the material and shape of the work material.

Although the use of a tool with high hardness seems to be good because it increases wear resistance, lengthens tool life, and improves cutting performance, even a slight impact can cause the edge of the cutting tools to break.

In addition to the material, the shape of the cutting edge is also an important factor. The sharper the cutting edge, the better the cutting performance, which results in less cutting resistance and a cleaner finish of the work material. However, a sharp tip reduces the strength of the tool and makes it prone to chipping.

The key to good cutting tool performance is to select the optimum cutting tool material and cutting edge shape according to the material and shape of the work material.