What Is a Hydraulic Chuck?

A hydraulic chuck, or power chuck, employs hydraulic pressure to secure a workpiece or tool. Its hollow design often features a through-hole for bar-shaped workpieces, making it suitable for high-precision machining.

Uses of Hydraulic Chucks

Mounted on machine tools like lathes and milling machines, hydraulic chucks are instrumental in securing workpieces for operations such as milling, drilling, and burnishing. Their ability to maintain stability at high speeds makes them indispensable for precise machining tasks.

Principle of Hydraulic Chucks

Utilizing Pascal’s Principle, hydraulic chucks distribute hydraulic pressure evenly to generate significant clamping force. This principle allows for efficient force transmission, enhancing the chuck‘s gripping power.

Types of Hydraulic Chucks

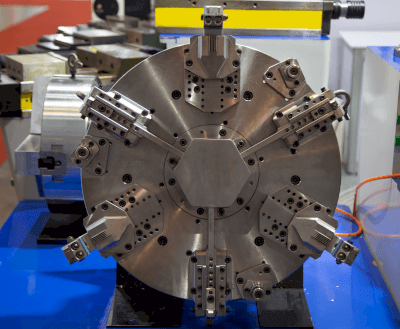

Hydraulic chucks for workpieces come in various jaw configurations, including 2-jaw, 3-jaw, and 4-jaw types, each suited to different shapes and sizes of workpieces. Specialized chucks like collet types and indexing chucks offer additional functionality for specific applications.

Tool-holding hydraulic chucks are designed for securing tools with high precision. They are available in standard, high-rigidity, and slim profiles to accommodate various machining needs.

Other Information on Hydraulic Chucks

1. Clamping of Workpiece

Workpiece clamping hydraulic chucks use a rotating cylinder to apply hydraulic pressure to the jaws, converting axial force into radial force for secure clamping. Features like through-holes for bar workpieces and proximity switches for jaw position and pressure monitoring enhance their versatility and safety.

2. Tool Clamping

Hydraulic chucks for tools provide high-precision clamping with minimal runout, ensuring stable machining accuracy and extended tool life. Their sealed design negates the need for oil replenishment, simplifying maintenance.