What Is a Tool Presetter?

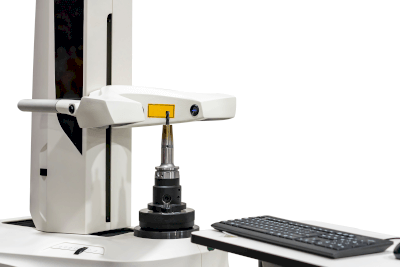

A tool presetter is a device used in machine tool operations to check for defects or dimensional variations in tools like drill bits. It’s essential for ensuring accuracy in the machining process, as a defective tool can lead to faulty operations and potentially render machined products unusable.

Tool presetters enable the inspection of a tool’s tip, shape, and size before its use, eliminating the need for risky and time-consuming in-machine inspections.

Uses of Tool Presetters

Tool presetters are commonly used in metalworking shops where machine tools are frequently operated. They help identify wear on drill bits and other tools, which can affect drilling speed, depth, and hole diameter. By using a tool presetter, operators can avoid such failures and maintain consistent quality in their work.

The measurements taken by tool presetters can be transmitted directly to the processing equipment for precise adjustments.

Principle of Tool Presetters

Tool presetters utilize three main methods to read the geometry of machining tools:

- CMOS Camera Method: This method involves capturing images of the tool using a CMOS camera and displaying them on a monitor. It provides a three-dimensional perspective and can rotate the tool for comprehensive inspection. While offering high performance, this method tends to be more expensive due to the use of a CMOS camera.

- Projection Type: This approach projects the tool’s shape using a light source. It allows for visual confirmation of the tool’s shape but cannot display three-dimensional details and outermost outlines. However, it is more cost-effective than the CMOS camera method.

- Contact Type: This type measures the tool’s size by direct contact. It can determine the outer diameter and length but not complex shapes or detailed dimensions. This method is the most affordable but offers limited information compared to the other types.