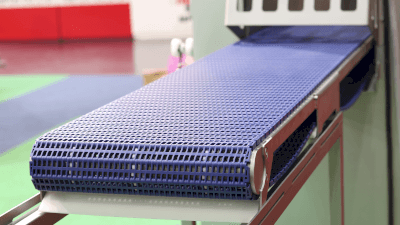

What Is a Plastic Chain Conveyor?

A plastic chain conveyor utilizes a plastic chain as its medium for conveying items. These conveyors are ideal for moving lightweight products, foodstuffs, and electronic equipment due to their light weight, ease of handling, and simplicity in installation and maintenance. They are a sustainable option, offering a quieter and environmentally friendlier alternative to metal conveyors.

Uses for Plastic Chain Conveyors

Plastic chain conveyors find applications across various industries:

1. Logistics

Used for transporting and sorting goods in warehouses and distribution centers, enhancing order fulfillment efficiency.

2. Food Industry

Preferred for transporting food products due to stringent hygiene standards, used in packaging and cooling lines.

3. Medical Devices

Essential in the assembly and inspection lines for medical devices, where cleanliness is paramount.

4. Electronics

Facilitates the transport of parts and products in the assembly and testing lines of electronic equipment.

Principle of Plastic Chain Conveyors

Plastic chain conveyors operate on a looped plastic chain driven by electric motors and pulleys. The chain’s design allows for both horizontal and vertical movements. However, plastic’s susceptibility to high temperatures limits its use to conditions below about 60°C.

How to Select a Plastic Chain Conveyor

Key factors in selecting a plastic chain conveyor include:

1. Conveyor Dimensions

Determine the conveyor length and width based on the size of the goods and the conveying route, considering space for potential future adjustments.

2. Speed

Choose conveyor speed based on material type and process requirements, with options for variable speeds to suit different needs.

3. Frame Material

Select frame material (e.g., stainless steel, aluminum) based on the operating environment and hygiene standards, particularly in the food industry.