What Is a Cap Screw?

A cap screw is a bolt with a cylindrical or countersunk bolt head and a hexagonal hole drilled in its upper end face.

Generally, “cap screw,” “socket screw,” and “hexagon socket head cap screw” are also used as synonyms.

The standards for cap screws are as follows:

- ASME/ANSI B18.3 Hexagon Socket Head Screws

Usage of Cap Screws

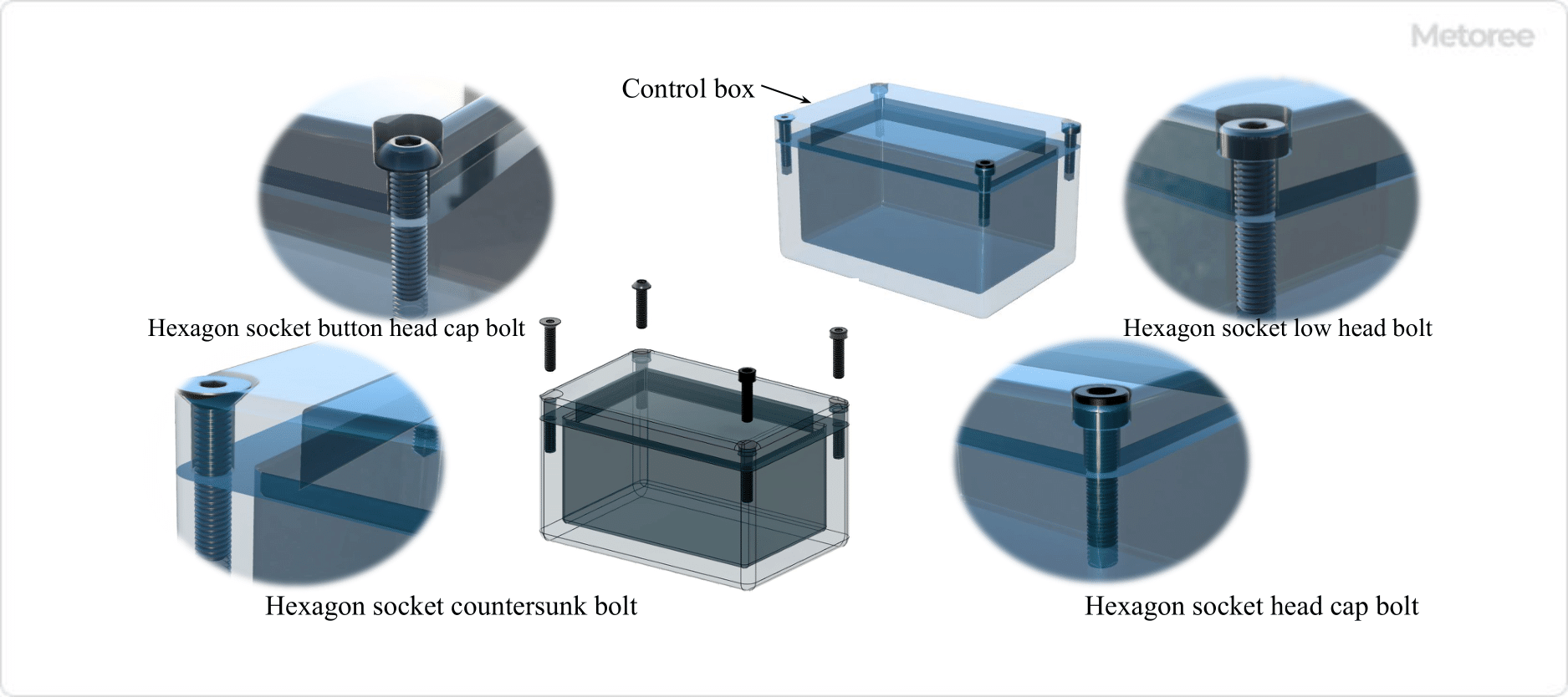

Figure 1. Example of cap bolt use (1)

Cap screws are primarily used to mount and secure components on small machines and equipment where space is limited for installation.

To tighten cap screws, use a tightening tool such as a hexagonal wrench (Allen wrench) appropriate for the size of cap screw. Compared to a wrench or a monkey wrench, a hexagonal wrench has the advantage of applying a stronger tightening force with less force and requiring less work space around the bolt when tightening.

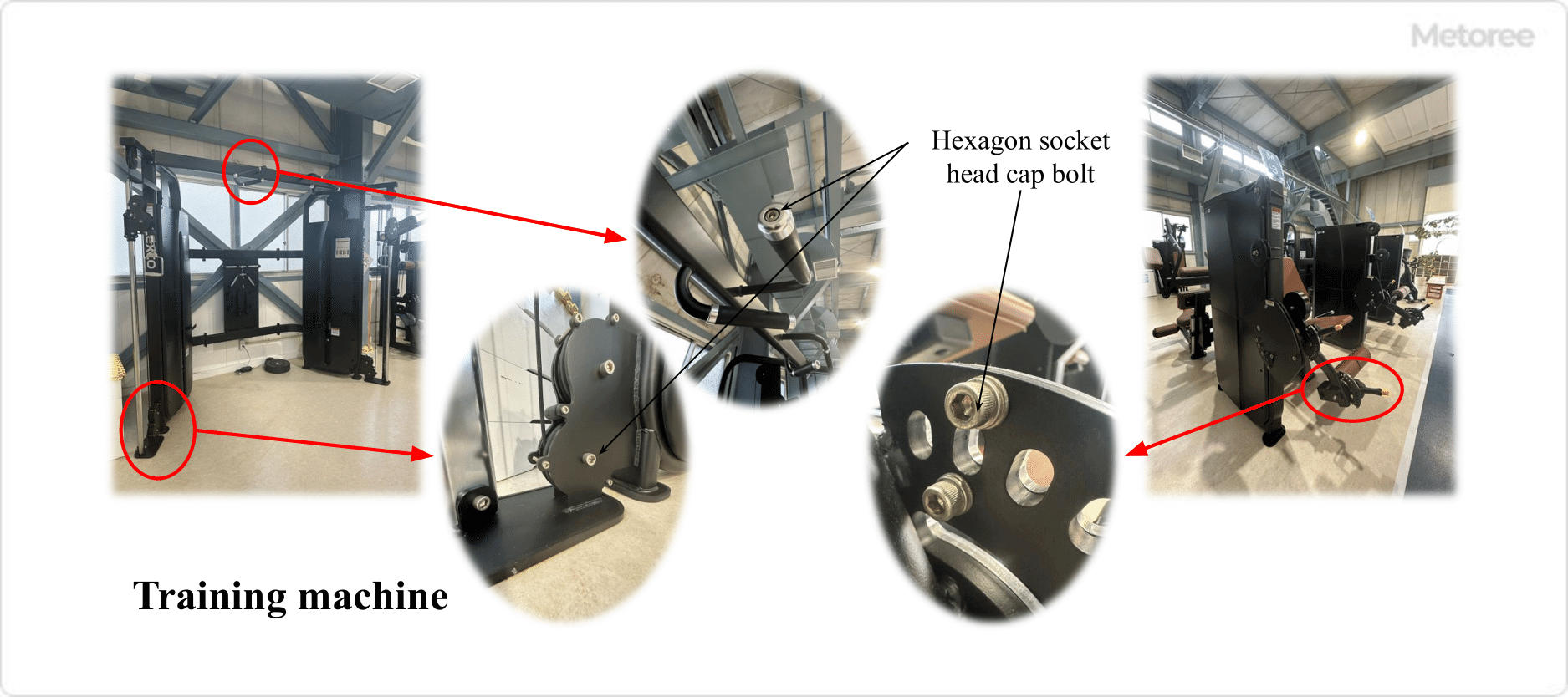

Figure 2. Example of cap bolt use (2)

However, since hexagonal wrenches are available in millimeter and inch sizes, care must be taken in selecting a hexagonal wrench. Also, by drilling a counterbored hole slightly larger than the diameter of the cylindrical head of the cap screw and slightly deeper than the height of the head, the cap screw can be installed without the head protruding.

Counterbore holes are drilled in the mounting area so that the bolt head is hidden. The interference between the bolt head and other parts is avoided, resulting in a clean and neat appearance.

Principle of Cap Screws

Cap screws are fastened by means of a screw (in this case, “screw” refers only to the screw shape), the same as an ordinary hexagonal bolt. Cap screws are often used to fasten directly onto a tapped female thread without using a nut.

Instead of inserting a wrench into the bolt head like a hexagonal bolt, a wrench with a hexagonal cross section is inserted into the hexagonal hole and tightened. For this reason, it is necessary to secure a space between the bolt heads and other parts. However, the cap screw tightening tool does not require space outside the bolt head because of the hexagonal wrench, allowing the cap screw to be placed close together.

Used when high tightening force and high strength are required. It is important to select the appropriate material and strength classification for the location and application.

Types of Cap Screws

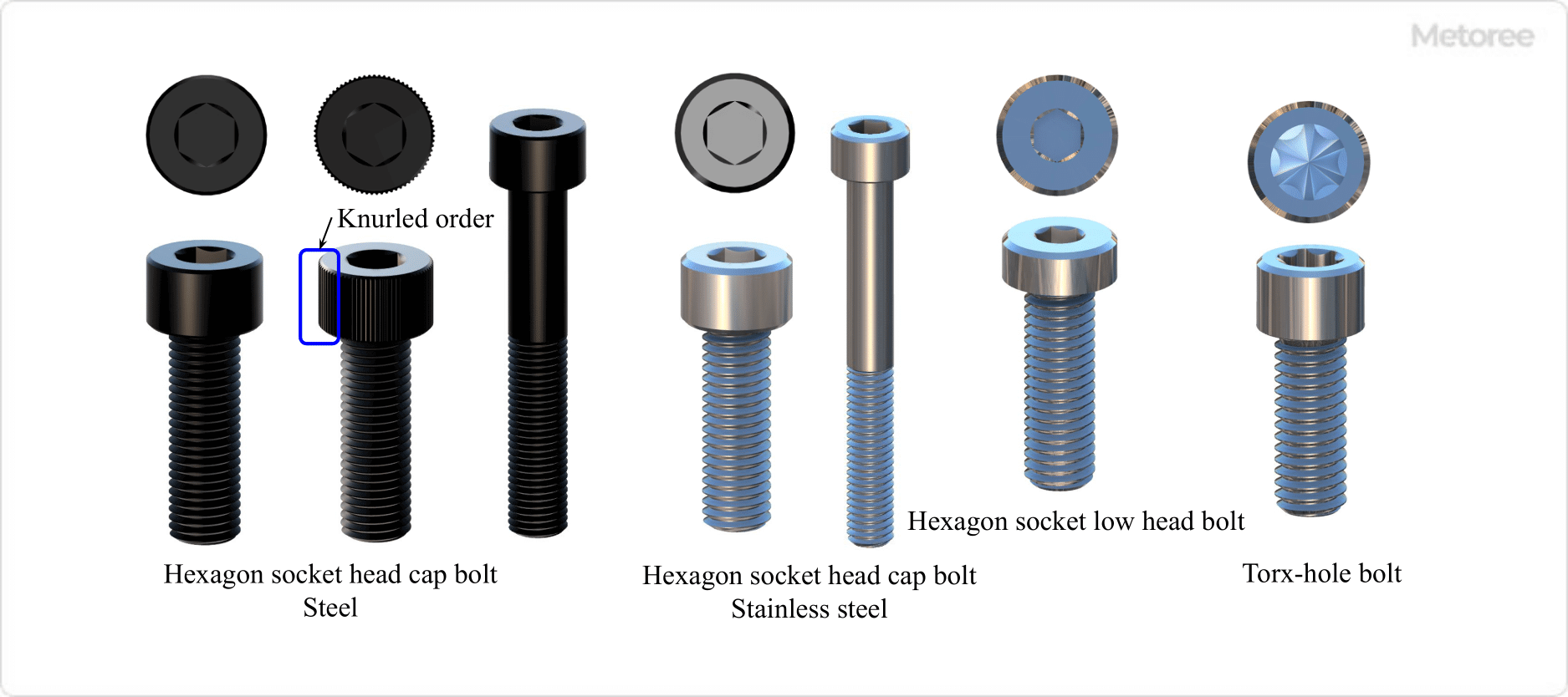

Figure 3. Type and shape of cap bolts (1)

Cap screws are classified by the shape of the cap screw head and the shape of the hole for the fastening tool.

Types by cap screw head shape are as follows:

- Hexagon socket head cap bolt

- Hexagon socket low head bolts

- Hexagon socket countersunk bolt

- Hexagon socket button bolt

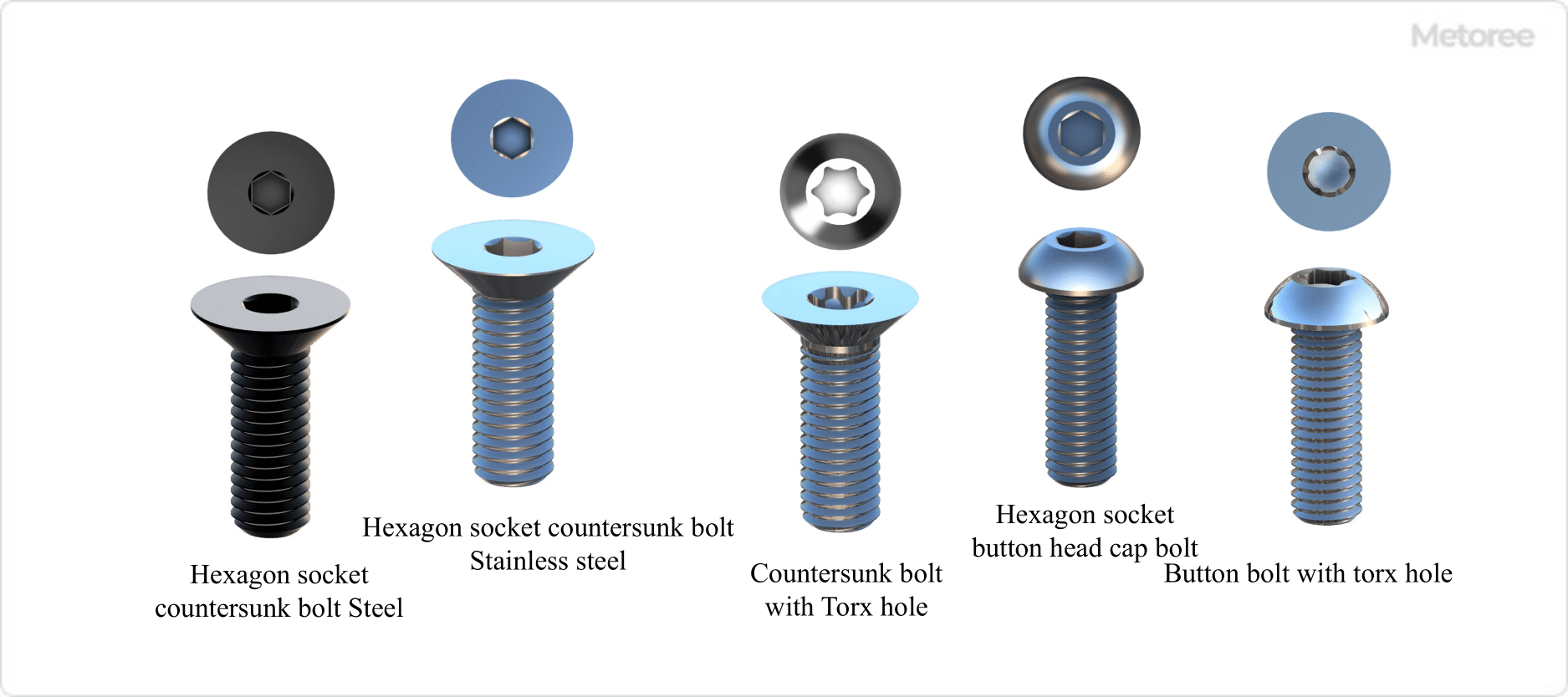

Figure 4. Type and shape of cap bolts (2)

In addition to the hexagonal hole, there is a hexagonal star-shaped groove Torx hole.

Other Information on Cap Screws

Tightening Tools for Cap Screws

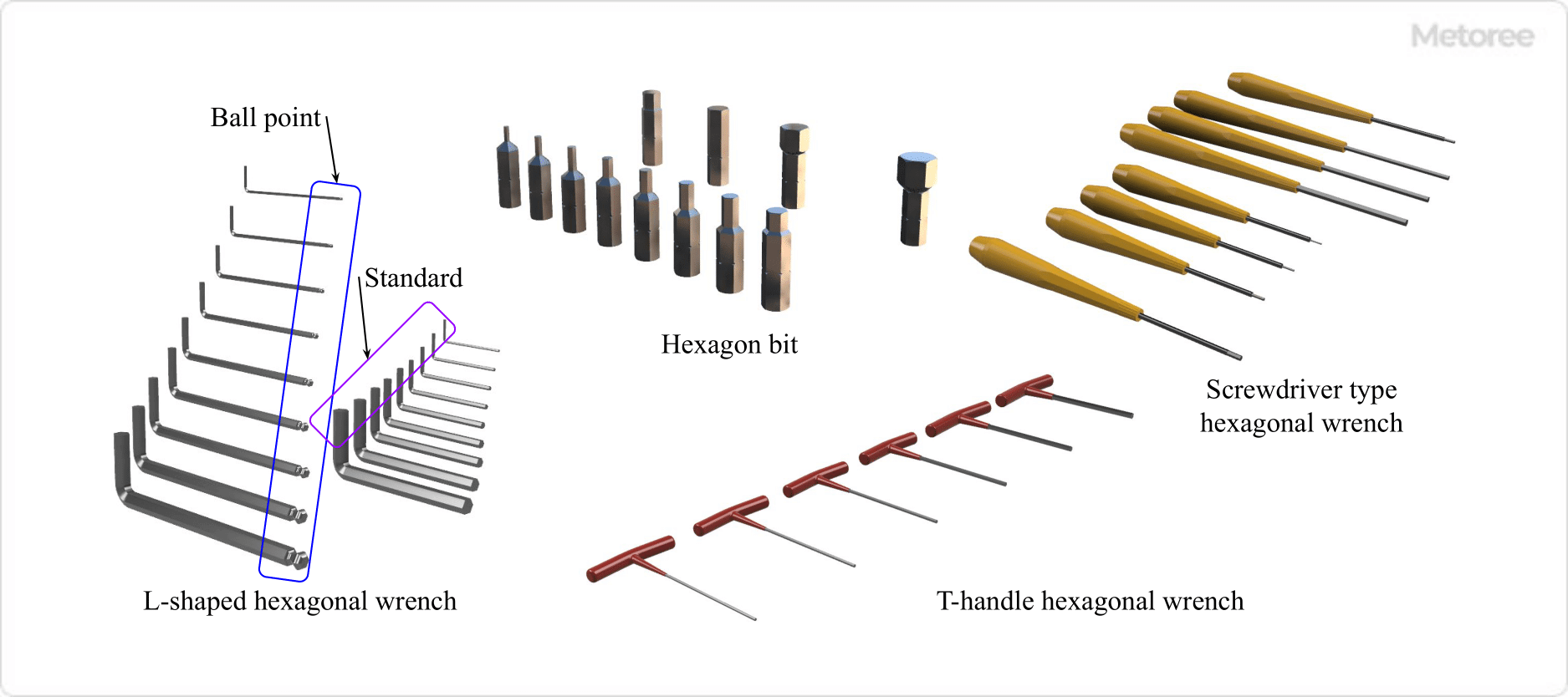

Figure 5. Type and shape of cap bolt tightening tool

The most commonly used tools for tightening cap screws are L-shaped Allen wrenches (hexagonal bar wrenches), T-handle Allen wrenches, screwdriver Allen wrenches, and hexagonal bits. Hexagonal wrenches and hexagonal bits have either a “flat” or “ball point” tip shape on the side where the cap screw is inserted.

The shape of the tip of the ballpoint is R-processed at the corner so that the hexagonal wrench can be tightened even when the hexagonal wrench is at an angle.