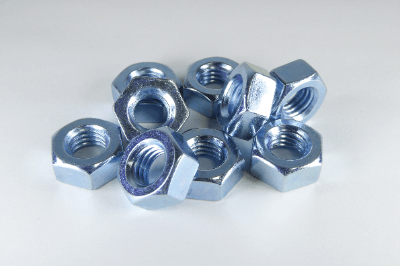

What Is a Hexagon Nut?

Hexagon Nuts are a fastening part with a hexagonal outer shape and a threaded center hole. Generally, Hexagon Nuts are not used by themselves, but are inserted between parts to be fastened, and screwed into threaded parts such as bolts.

Hexagon Nuts are a fastening part with a hexagonal outer shape and a threaded center hole. Generally, Hexagon Nuts are not used by themselves, but are inserted between parts to be fastened, and screwed into threaded parts such as bolts.

ISO Standard

- ISO 4032:2012 Hexagon regular nuts (style 1) – Product grades A and B

- ISO 4033:2012 Hexagon high nuts (style 2) – Product grades A and B

- ISO 4034:2012 Hexagon regular nuts (style 1) – Product grade C

- ISO 4035:2012 Hexagon thin nuts chamfered (style 0) – Product grades A and B

- ISO 4036:2012 Hexagon thin nuts unchamfered (style 0) – Product grade B

- ISO 8673:2012 Hexagon regular nuts (style 1) with metric fine pitch thread – Product grades A and B

- ISO 8674:2012 Hexagon high nuts (style 2) with metric fine pitch thread – Product grades A and B

- ISO 8675:2012 Hexagon thin nuts chamfered (style 0) with metric fine pitch thread – Product grades A and B

Principles of Hexagon Nut

Hexagon Nuts tighten and secure parts using the threaded fastening principle. By turning the hexagon nut, the nut and bolt contact the part to be fastened, and then tightening the nut further, the following forces are exerted.

- Compressive force (force that pushes in the direction of the axis of the clamp) on the part to be clamped

- Tensile force (reaction force of the part to be fastened) on a screw such as a bolt

As a result, the following frictional forces are generated and the screw remains tightened without loosening.

- Between the male thread and female thread

- Seat surface of the bolt and nut (surface in contact with the part to be fastened)

Uses of Hexagon Nuts

Nuts come in a variety of shapes and types, but hexagonal nuts, in particular, are probably the most commonly used for fastening parts.

Hexagon Nuts are used in a very wide variety of situations, from general purpose to special applications, from very small parts to large parts, from very small parts such as precision instruments to household DIY, railroad tracks, and general industrial equipment and facilities.

Hexagon Nuts are characterized by their hexagonal shape, which allows tools such as wrenches and wrenches to be hung on them at 60-degree intervals, allowing them to be tightened at small angles. They are also very easy to use since many general-purpose tools are compatible with them.

Types of Hexagon Nuts

There are a wide variety of locks that have anti-loosening functions, and their respective functions and features must be used effectively. In addition to the above, there are many other types of products, including standard products, special-purpose and specially designed products.

How to Use Hexagon Nuts

If Hexagon Nuts are not used properly, the bolts on the mating side may be damaged, or products or equipment assembled with hexagon nuts may be damaged.

To prevent this, the following points must be observed:

- Tightening force must be within the allowable range to prevent damage to the hexagon nut and bolt.

- Repeated forces (e.g., vibration) applied to the hexagon nut and bolt must be within the allowable range.

- The seating surfaces of the hexagon nut and bolt (the surfaces that come into contact with each other, not the surfaces that the tool touches) must be within the allowable range. The seating surfaces of the hexagon nut and bolt (the surfaces that contact each other, not the surfaces that the tool touches) must not cause the object to be tightened (metal, wood, etc.) to cave in.

- Tightening the hexagon nut and bolt must not damage the object to be tightened.

Other Information on Hexagon Nut

1. Material and Surface Treatment of Hexagon Nut

Hexagon Nut materials, mainly iron, alloy steel, stainless steel, titanium alloy, copper and copper alloy, aluminum and aluminum alloy, nickel alloy, etc. Generally, materials are selected according to requirements such as strength and corrosion protection.

When a bolt or nut is subjected to a heavy load or used in equipment where human life may be at stake, the material of the hexagon nut has a significant impact on its strength, so it is necessary to select a material with sufficient strength requirements.

The presence or absence of measures against corrosive environments is also an important factor in material selection. Material selection should be based on the corrosive environment so that the hexagon nut does not lose weight and strength due to corrosion.

Electrical corrosion is also an important factor. If the material of the hexagon nut differs from the material of the mating mechanical element or the object to be fixed, a difference in metal potential may result in corrosion. Particular attention should be paid in the case of aluminum and stainless steel.

The following surface treatments are available for hexagon nuts, which are selected according to appearance quality and price:

Electroless nickel, trivalent chromate, unichromate plating, zinc plating, chromate plating, nickel plating, chrome plating, parker, dacrotized, paint/coating, silver, copper, tin plating, etc.

2. Preventing Hexagon Nuts From Loosening

The following measures can be taken to prevent loosening of hexagon nuts:

Initial loosening measures

A spring washer or disc spring washer is inserted between the hexagon nut and the part to be fastened. This function compensates for the initial reduction in axial force and has no effect on preventing slippage of the seating surface, thus it cannot prevent loosening due to the nut’s return rotation.

Countermeasure against reduction in axial force (non-return stop)

- Mechanical anti-rotation method

To prevent the nut from turning, the following parts are used to secure the nut to the threaded side.

Example: grooved lock nut + split pin, lock nut with external teeth, wire lock, etc. - Incremental return torque method

This method increases the resistance to rotation between the male and female threads in order to prevent loosening by using the following parts.

Example: Nylon insert locknut, ring locknut, flex locknut (slit nut), flange nut (with serration), etc. - Return Rotation Prevention (Loosening Prevention)

-

- This method increases friction between the male and female threads to prevent the nut from rotating back. Double nuts are applicable.

- This method applies an adhesive or other substance to the threaded part to adhere it. Anaerobic adhesive application, screws with adhesive, etc. fall under this category.

- This method uses two types of nuts with eccentric, wedge-shaped concavities and convexities. The entire thread of the convex nut is pressed against the bolt side, and the entire thread of the concave nut is pressed against the threaded portion of the bolt on the opposite side. The “wedge” effect is utilized. Hard locknuts fall into this category.