What Is a Cam Clutch?

A cam clutch is a one-way clutch that transmits torque in only one direction. It is also called a cam-type one-way clutch or roller-type one-way clutch.

One of the characteristics of a one-way clutch is that it can only rotate in one direction, like a bicycle pedal. A cam clutch has the same characteristic. When a rotational torque opposite to the torque in the specified direction is applied, the clutch does not engage internally, causing it to spin out of alignment.

Cam clutch is widely used in automobiles, helicopters, conveyors, and other industrial machinery.

Uses of Cam Clutches

As a type of one-way clutch, it is mainly used when torque is transmitted in only one direction. Taking advantage of its idling property when reverse rotational torque is transmitted is sometimes used as a component to prevent reverse rotation and blurring of the drive components.

It may also be used as a clutch for two-speed drives by using the properties of spinning and meshing differently. By connecting gears and other drive components to a shaft, mounting two cam clutches on each end of the shaft, and connecting different drive motors with varying speeds to the cam clutches, it is possible to use two various drive sources by having one motor spinning and the other spinning.

Combining drive components makes it possible to combine the torques of two drive motors to create a dual drive.

Principles of Cam Clutches

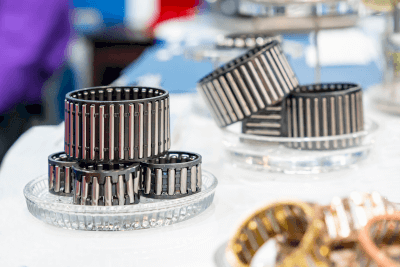

Cam clutches have an outer and inner ring, with a cam and spring built between them. The cams are laid regularly between the outer and inner rings, like balls in a ball bearing.

What differentiates cams from ball-bearing balls is their shape. Instead of a regular circle, they have a particular oval shape. The lower half is a traditional circle, and the upper half is a triangle with two sides. This is done to prevent the cam from tipping over inside the clutch.

When torque is applied to the cam clutches in the direction of engagement, the cam acts as a bar between the outer and inner rings, thereby engaging the outer and inner rings and applying rotational torque in the same direction.

A groove is cut in the cam for spring, and the spring is installed to cover the entire cam. This spring tightens the cam so that the cam can easily tilt in the direction of engagement. The outer and inner rings do not engage when reverse rotational torque is transmitted because this spring pulls the cam in the direction of engagement. The cam, tilted toward engagement by the spring, slides out of engagement when reverse rotary torque is applied, releasing the torque.