What Is a Rotary Valve?

A rotary valve is a valve that controls the amount of fluid or powder cutout.

A rotary valve is a valve that controls the amount of fluid or powder cutout.

Pneumatic conveying using compressed air is mainly used for conveying powder, but it is necessary to supply a fixed quantity to prevent clogging. However, unlike liquids and gases, the amount of powder cannot be controlled by the opening of a valve, so the cutout volume is controlled by a rotary valve.

Rotary valves are very commonly used in the powder industry, but their disadvantage is that they are large and heavy due to the need for continuous rotation.

Uses of Rotary Valves

Rotary valves are used in industrial equipment. Their main purpose is to control the amount of material cut out.

Specific applications are as follows:

- Fuel adjustment in coal-fired power plants

- Cutting out smoke ash from boilers

- Cutting out food ingredients in food factories

- Cutting out powdered chemicals at pharmaceutical plants

- For feeding raw materials in cement plants

Rotary valves are used for feeding powdery materials. They are installed at the bottom of hoppers of pneumatic conveyors and before feeding into agitators. They should be used to control the feed rate, especially for grinding mills, which can become clogged if a large amount of powder enters the mill.

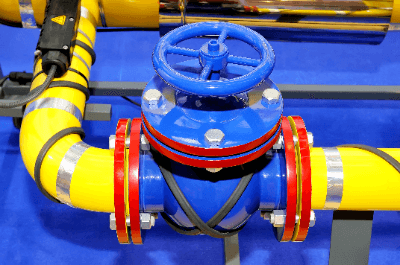

Principle of Rotary Valves

Rotary valves have a different structure from ordinary valves. Inside the valve, there is a rotor with blades, and each blade is divided into sections. As the rotor rotates, it continuously discharges the powder that has accumulated in the partitioned areas. The amount of material discharged can be controlled by the valve size, the number of rotor blades, and the number of rotations.

When the rotor and case come into contact with each other inside the machine, they scrape off each other and mix into the material. This is called contamination. Since this is a major problem in the food industry, countermeasures such as the use of large clearance blades are taken. A magnet can also be installed under the rotary valve to prevent contamination.

Rotary valves require a drive source. Most of them use motors. Therefore, the cutout volume can be adjusted by variable frequency devices such as inverters.

Other Information on Rotary Valves

1. Clogged Rotary Valve

Because the material to be handled by the rotary valve is a powder, clogging may occur. Therefore, clogging countermeasures are mandatory in many cases. Clogging frequently occurs when the powder is sticky. Clogging can also occur when moisture is absorbed during the powder handling process or when lumps that have stuck to the primary side are fed in at once.

Effective countermeasures are to use raw materials with low viscosity or to dry them in the pretreatment process. Another measure is to install a vibrating motor, called a vibrator, to prevent powder from sticking to the primary side of the rotary valve. If the raw material absorbs moisture, measures such as installing tress piping to keep the powder warm can also be taken.

In some cases, the powder may gradually stick to the partitions between the blades of the rotary valve. Some models are equipped with scraper blades. By employing these, it is possible to scrape out the powder so that it does not remain in the partition.

2. Maintenance of Rotary Valve

The following are the general maintenance items for rotary valves:

- Replacement of packings on the flange surface that seal powder

- Replacement of gland packing at the shaft seal

- Replacement of motor and rotor bearings

- Replacement of drive chain

- Maintenance of the drive motor

For models with a scraper attached, maintenance of the scraper shaft and replacement of gears are also included.

In case of overhaul, the following deterioration diagnosis is also performed:

- Measurement of shaft fit

- Measurement of shaft runout

- Measurement of the wear condition of the gland packing part

Since the gap between the rotor and casing has dimensions designed by the manufacturer, it is important to check the dimensions from the case to the shaft end before disassembling. Failure to do so may cause contamination due to contact between the case rotor and scraper.