What Is Riveting Machinery?

Riveting machinery are machines that join multiple parts by crimping rivets using rotation and pressure.

These machines are commonly used for joining items like scissors, casters, and door hinges. Riveting provides a semi-permanent joint that is less likely to loosen with vibration compared to screws and bolts.

Uses of Riveting Machinery

Riveting machines are used in various industries due to their compact size, safe and convenient operation, and stable performance. They are particularly prevalent in the automotive industry for assembling car body parts such as doors, seats, wipers, hub bearings, and seat belts. Other applications include aircraft, ships, railroad cars, bicycles, turbines, medical equipment, personal computers, cameras, air conditioning units, kitchen utensils, artificial limbs, handcuffs, manhole covers, and electrical switches.

Principles of Riveting Machinery

The riveting machine operates by lowering a forming tool onto the rivet shaft or other protruding parts of the workpiece, pressing down to crimp them. This process can be finely tuned to accommodate variations in workpiece height, thickness, rivet length, and protrusion length.

The method ensures that only the rivet head is pressure-welded and plastically deformed, leaving the body of the rivet intact. This results in stable performance without stressing the joined parts.

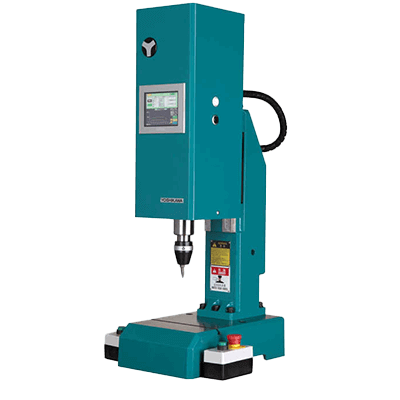

Different models of riveting machinery are available, including electric, hydraulic, and pneumatic types, which cater to various needs such as large air-core rivets and solid rivets. The machines come with seven major types of heads — mountainous, round, flat, flat dovetail, round dovetail, pot, and hollowed out — selected based on the desired finished shape.