What Is a Roll Crusher?

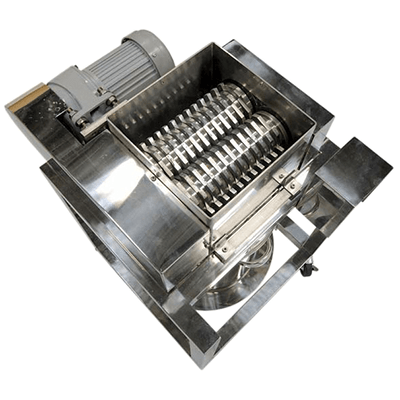

A roll crusher crushes using a cylindrical rotating tube called a roll, which rotates intermeshing to compress and pulverize hard objects such as ores in between.

Crushing is generally performed by compression using two rolls, but some crushers, called single roll crushers, consist of a single roll.

Single-roll crushers are used for relatively soft objects such as limestone or coal.

Uses of Roll Crushers

Here are some uses of roll crushers.

Roll crushers crush hardwood, concrete, stone, ceramics, glass, and other materials because of their mighty crushing power, even at low rotational speeds.

They are also used for crushing challenging-to-process materials such as electronic components and battery materials.

Higher rotational speeds can also be used for more substantial compaction and higher efficiency.

Roll crushers are used in industrial waste and recycling and are installed at incineration plants and industrial waste collection sites.

Principle of Roll Crushers

The following is an explanation of the principle of roll crushers.

A roll crusher is a crusher that uses compaction action.

Roll crushers have two rolls constantly rotating so that when the object to be crushed passes between these rolls, pressure is applied to the object from the rolls, and is destroyed.

The degree of crushing of the object varies depending on the pressure applied and the specifications of the rollers.

The pressure can be changed by changing the gap between the two rolls or adjusting the rotation speed.

Regarding roller specifications, there are materials and shapes, such as alumina, rollers with devil’s blades, and corrugated rollers.

Also, one of the two rollers has a spring mechanism on one side.

This is to maintain a constant spacing between the rolls and prevent objects over the allowable amount from passing between the rolls.