What Is a Differential Pressure Switch?

A differential pressure switch is a device designed to detect pressure differences in fluids and activate a switch accordingly. Commonly installed on pipes or tubes, it functions by comparing the pressure between two input ports: one with higher pressure input and the other with lower. The switch is calibrated to trigger at a predetermined pressure differential.

Upon exceeding the set pressure difference, the switch’s internal mechanism changes its state. For smaller measured pressure differences, it is sometimes known as a differential pressure switch.

Applications of Differential Pressure Switches

These switches have diverse applications in multiple industries:

- Fluid Supply and Discharge Control: Used in managing the operation of pumps based on fluid pressure differences.

- Filter Clogging and Pressure Drop Monitoring: They signal warnings or indicate the need for filter replacement when a specific pressure differential is detected, commonly seen in industrial settings.

Principle of Differential Pressure Switch

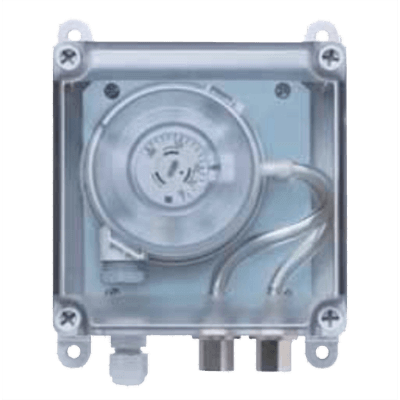

Differential pressure switches primarily utilize bellows or diaphragms. These components deform in response to pressure changes, with a spring mechanism to reset their position. The spring tension sets the switch’s operating pressure differential. The switches also contain internal electrical contacts that respond to diaphragm movements, altering the switch’s state. Protected by metal or plastic enclosures, these components are safeguarded from external elements.

How to Select a Differential Pressure Switch

Key factors to consider when selecting a differential pressure switch include:

- Contact Quantity and Type: Options range from single to dual-contact switches, with specific models for low-voltage applications.

- Pressure Range: Choose a switch that operates within the required minimum and maximum pressure settings.

- Diaphragm Material: Material choice depends on the measured fluid, with options like fluorine or nitrile rubber, and special treatments for specific uses.

- Connection Port: Ensure compatibility with system and piping, choosing from threaded or flanged types.