What Is a Freeze Dryer?

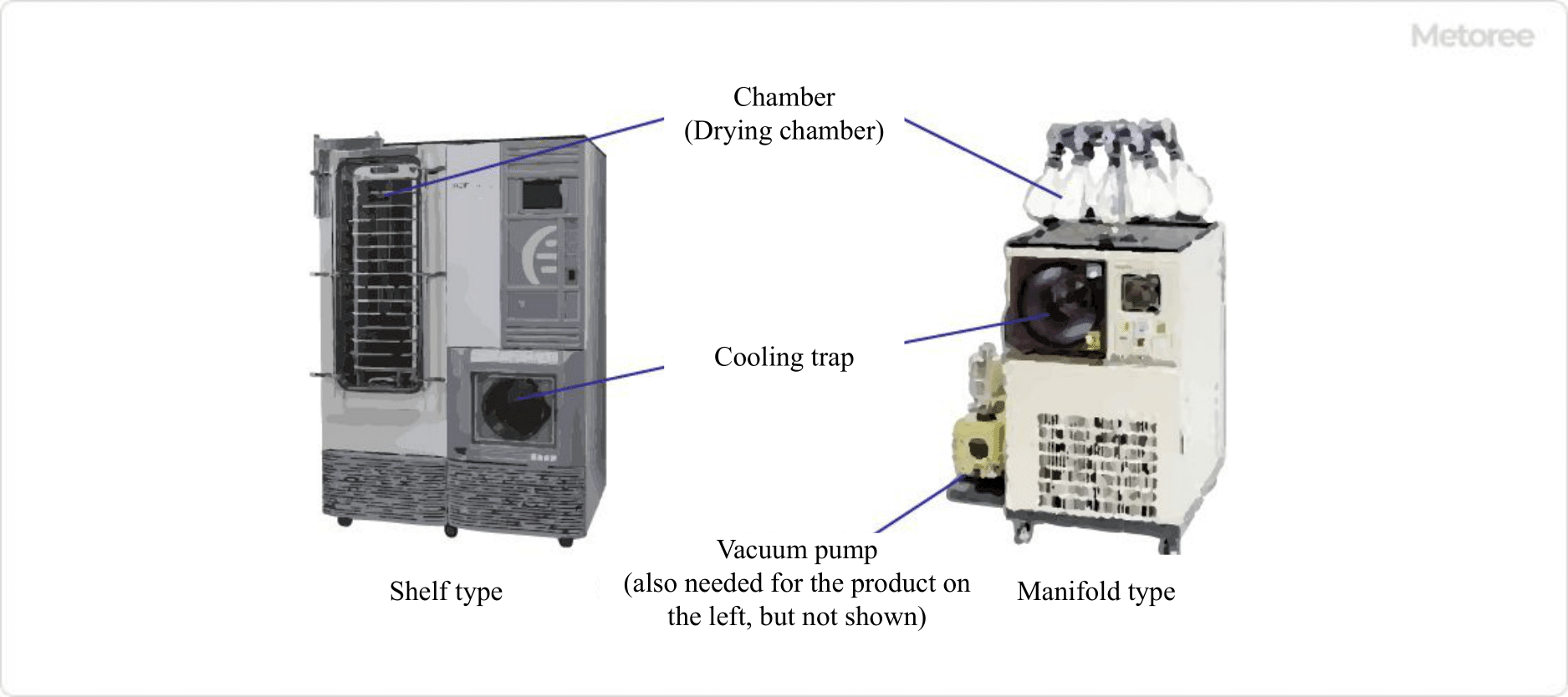

Figure 1. Structure of a freeze dryer

A freeze dryer is a device used to remove water from a sample while it is in a frozen state.

There are three fundamental equipment configurations:

- Chamber (Drying Chamber): Stores and dries the sample.

- Cooling Trap: Collects vapor that has been vaporized in the condenser and condenses it again.

- Vacuum Pump: Reduces the pressure inside the device.

This system removes water and solvents by depressurizing pre-frozen samples in the chamber and sublimating ice, allowing for drying while minimizing structural changes.

Uses of Freeze Dryers

Freeze dryers are used for materials that can deteriorate due to moisture when stored at room temperature, in refrigerated storage, or frozen storage for an extended period.

Freeze-dried samples can be stored at room temperature for an extended period if properly sealed. Moreover, the cost of equipment maintenance during storage is lower compared to other storage methods.

Specific uses of this method include:

1. Food Products

Freeze-dried foods, such as instant coffee, miso soup, and space food, can be stored for an extended period, are suitable for transportation due to their dry and lightweight nature, and maintain their flavors well.

2. Pharmaceutical Products

Freeze dryers are used to produce injectable drugs like heat-sensitive proteins and enzyme preparations due to their ability to create powder without heating. Research is also underway to preserve animal sperm using freeze dryers.

Principle of Freeze Dryer

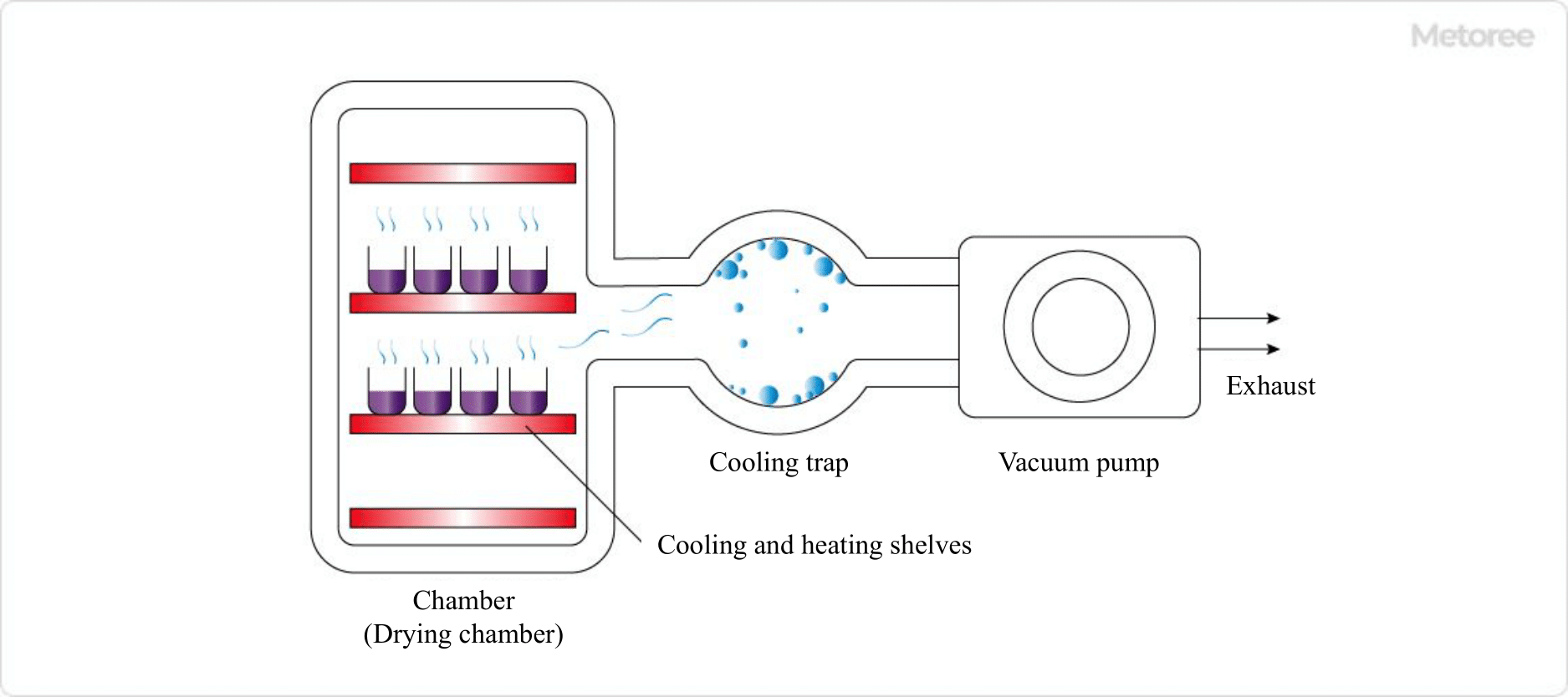

Figure 2. Schematic diagram of a freeze dryer

The freeze-drying process involves the following steps:

- Pre-freeze the sample to freeze it thoroughly.

- Store the frozen sample in the chamber (drying cabinet).

- Primary freezing: A vacuum pump is used to reduce the pressure inside the chamber, allowing the solvent to sublimate from the sample. In the shelf type, heat energy lost during sublimation is compensated for by heating the shelf, enabling efficient drying.

- Secondary freezing: In the shelf type, the shelf temperature is raised to remove bound water that has been incorporated into the solute components. This is a relatively short process.

- Release the decompression and remove the sample. In the shelf-type freeze dryer, vials can be stoppered before decompression is released by using a stoppered shelf and stoppered vial.

The sublimated water vapor is cooled in a device called a cooling trap and collected as ice again. The faster drying occurs when there is a greater temperature difference between the drying chamber and the cooling trap.

For food products, they are easy to dissolve and rehydrate with water or boiling water. However, once the seal is broken, they are prone to oxidation, moisture absorption, and quicker deterioration.

Types of Freeze Dryers

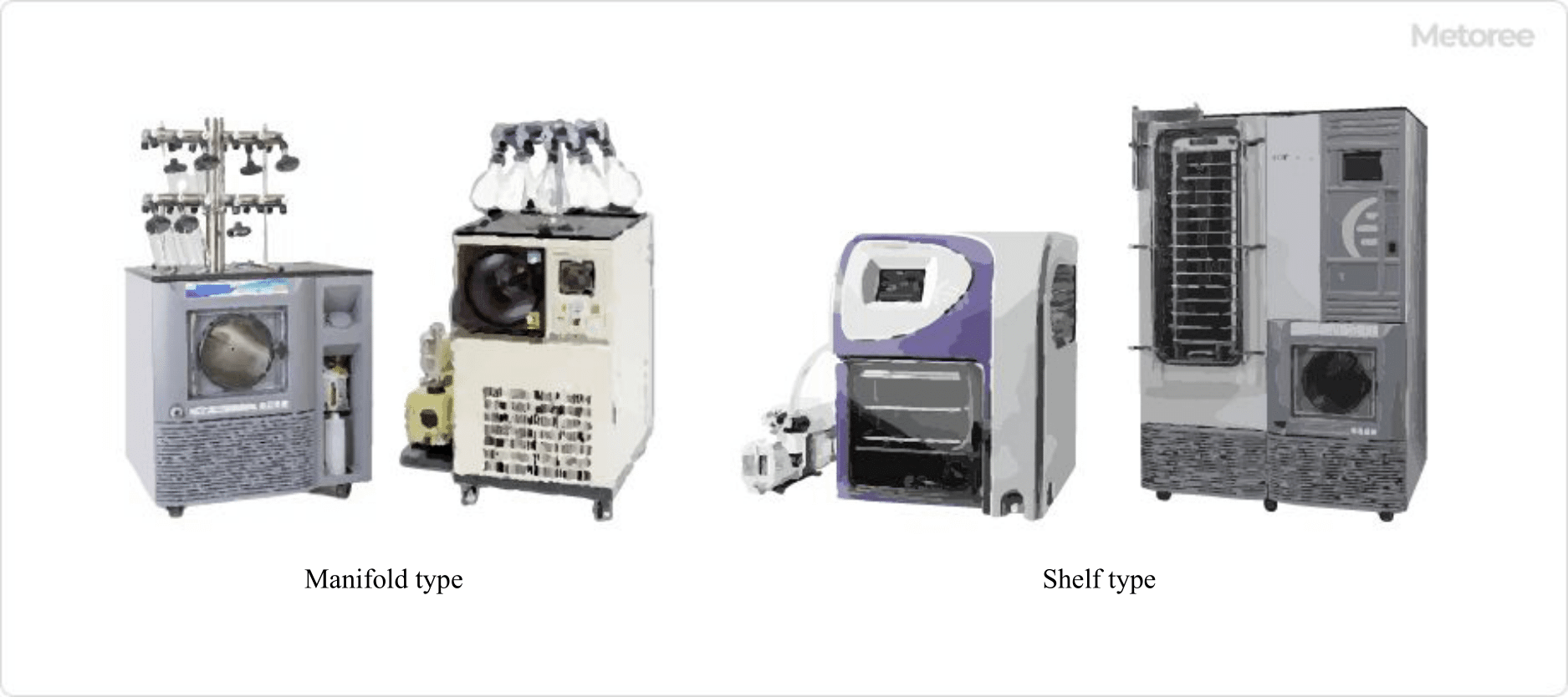

Figure 3. Various freeze-drying machines

There are two primary types of freeze dryers: “manifold type” and “shelf type.”

They come in various sizes, from small ones used for laboratory research to large ones for manufacturing purposes. Drying capacities range widely, from 150 mL for small models to over 100 L for large models.

1. Manifold Type

The manifold type is relatively small in scale and primarily suitable for basic research, whereas the shelf type can be used on a broader scale.

2. Shelf Type

Shelf-type freeze dryers can control temperature by heating the shelves. They can efficiently compensate for the thermal energy required for sublimation, making them suitable for drying samples. Some shelf plate-type products also have a stoppering function. By using stoppering vials as sample containers and operating the stoppering shelf, the chamber can be automatically stoppered while maintaining a vacuum.