What Is an Impeller?

An impeller is a rotor attached to a pump or fan spindle.

An impeller is a component that exerts pressure on a fluid. In a pump, the impeller rotates inside the casing, applying pressure to the fluid by centrifugal force. Screws, which provide propulsive pressure to ships, are also a type of impeller.

If the impeller impeller is exposed to the outside, it is called an open impeller. On the other hand, if the impeller is covered by side plates, it is called a closed impeller.

Uses of Impellers

Impellers are used in a wide range of products and fields. Open impellers and closed impellers are used in different ways.

1. Open Impeller

- Screws of ships

- Fans in electric fans and ventilation fans

- Air conditioner fans

- Slurry transport pumps

Open impellers are mainly used for equipment with relatively low applied pressure.

2. Closed Impellers

- Large blowers and compressors

- High-head (pressure) pumps and pure water conveying pumps

Closed impellers are used in high pressure applications. In pumps, open impellers are most commonly used in small-sized pumps, while closed impellers are most commonly used in medium-sized and larger pumps.

They are also used according to the characteristics of the fluid to be distributed. For clean liquids such as pure water, closed impellers are used.

Principle of Impeller

In centrifugal pumps, centrifugal force is applied to gases and liquids by the rotation of the impeller, moving them outward. As a result of these colliding with the casing, etc., the internal pressure increases and tries to escape toward the discharge port. As the gas/liquid is discharged, the area around the suction port becomes negative pressure, and new gas/liquid is sucked in. This is the principle of gas/liquid supply by an impeller.

Impellers are most often used to refer to impellers for pumps and blowers, but they are also sometimes used to refer to the propellers of agitators. Agitators are used inside beakers or liquid storage tanks to agitate the interior. In agitators, as in the above, the centrifugal force of the Impeller is converted into agitation energy.

Types of Impellers

Impellers come in a variety of types and shapes.

1. Radial Flow Type

Water passing through the impeller flows in a radial direction, and the shape of the blades is a simple two-dimensional curved surface. It is characterized by high pressure in relation to the flow rate, and is used in circulating pumps and boiler feed pumps.

2. Oblique Flow Type

This type of impeller has a curved vane flow line and an obliquely inclined outlet. It is characterized by a higher flow rate than the radial flow type and is used for cooling water pumps.

3. Axial-Flow Type

This type of impeller is same shape as an electric fan and also has an electric motor shaft inside the tube. While the pressure is low, the flow rate is high. It is used for drainage pumps during floods.

4.Vortex Type

This type of impeller has a large gap between the casing and the impeller. Since the gap allows solids to pass through, this type is used for pumping liquid mixed with solids. This type is used in pumps for pumping sewage.

5. Asteroid Type

This is a type of full-open impeller with a shape similar to the blades of a vacuum pump. It is used for pumping liquids mixed with gas.

Various other shapes are also available, such as the screw volute type, non-clog high-efficiency type, and balanced type.

Other Information on Impellers

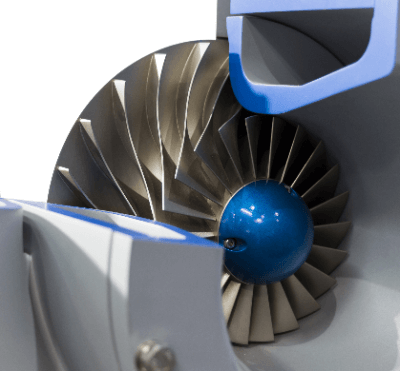

1. Impeller of a Turbofan

A turbofan is a type of centrifugal blower. The impeller of this blower is characterized by its high energy efficiency and low noise level by having the impeller facing backward with respect to the direction of rotation. It is used for microwave hoods and ducts.

2. Closed Impeller Features

A portion of the fluid in the pump gets stuck in the rotating vortex and stays there. A large amount of stagnant fluid not only causes a large energy loss in the pump, but also risks the actual flow rate to be smaller than the design flow rate.

To solve these problems, a closed impeller was devised in which a cover is installed on the impeller. The cover on the impeller reduces fluid leakage and improves pump efficiency and flow rate.

Because of the disk friction caused by the side plates, losses occur even with a closed impeller, but the closed impeller is characterized by its ability to pump fluid efficiently. Comparing open impellers and closed impellers, open impellers have a high flow rate and low head, while closed impellers have a high head and low flow rate.