What Is Reverse Osmosis Equipment?

Reverse osmosis equipment is a device that uses reverse osmosis membranes to remove impurities such as chlorinated organic compounds and heavy metal ions from water, thereby purifying the water to a high degree.

Water purified by reverse osmosis equipment is called RO water.

The main substances to be removed are heavy metal ions, bacteria, and chlorinated organic compounds, and 99.9% of these substances can be removed. The specific principle is described below, but to briefly describe it, pressure is applied to non-pure water, impurities are blocked by the reverse osmosis membrane, and only high-purity water is allowed to permeate.

Uses of Reverse Osmosis Equipment

Although there are a wide variety of uses, the majority of applications are for seawater desalination. In countries like Japan, where water resources such as rivers are abundant, there is no need for seawater desalination equipment, but there is great demand for it in Southeast and Middle East Asia.

Principle of Reverse Osmosis Equipment

RO systems apply reverse osmosis to purify pure water. When pure water is put in one side and non-pure water in the other, water moves from the pure water side to the non-pure waterside in order to equalize the density of the two. This pressure is called osmotic pressure.

Reverse osmotic pressure, on the other hand, refers to a phenomenon in which pressure is applied to the non-pure water side, causing only water to move. This allows the purification of pure water that does not contain impurities. Because of this principle, the selection of the reverse osmosis membrane is important for the purification of pure water. The smaller the pore size of the reverse osmosis membrane, the higher the purity of the water, but the slower the purification speed and the higher the pressure required. Therefore, the amount of impurities in the non-pure water and the degree of purity required must be taken into consideration.

Another important point to note when using reverse osmosis equipment is that pretreatment must be performed. The pore size of reverse osmosis membranes is very small, so if water with high impurities such as industrial water or well water is used, it will quickly become clogged and cause a malfunction. Therefore, it is necessary to filter the water with a coarse filtration membrane before use. Generally, as long as the purity is at the level of tap water, there is no problem using the water as it is.

Advantages of Reverse Osmosis Equipment

The greatest advantage of reverse osmosis equipment is that there is no need to worry about wastewater treatment; reverse osmosis equipment generates concentrated water in order to obtain clean water. If the raw water is industrial water, the concentrated water can be disposed of as is because it contains no hazardous substances. Ion exchange resins use acid or alkali to regenerate the resins, but they do not comply with effluent standards unless pH adjustment or other modifications are made.

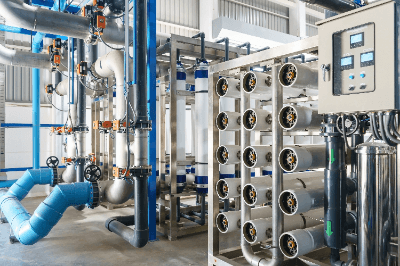

Example of Reverse Osmosis Equipment Installation

Reverse osmosis equipment saves space and makes it easy to obtain water of near-ultrapure water quality. Examples of installation are:

1. Research Facilities

Small research facilities purchase produced water in bottles or cubitainers, but in some cases, small RO systems are introduced to compare costs based on the amount of water used.

2. Printed Circuit Board Manufacturing

In the printed circuit board manufacturing process, it is necessary to clean the chemicals that adhere between the various surface treatment processes. This is a very precise process and requires a supply of clean water to prevent impurities from being brought into the next process, and there are many cases where RO water is used.

3. Plating and Other Surface Treatment Processes

In surface treatment processes such as plating, it is necessary to rinse water after each process in order to avoid introducing the treatment solution to the next process. Especially in the case of precision plating, the quality of the rinse water may be higher than that of RO water in order to maintain quality.

4. Pretreatment of Ion Exchange System

In an ion exchange system for producing ultrapure water, reverse osmosis equipment may be incorporated in the front-end stage to reduce the load on the ion exchange resin. If the raw water used contains a large amount of impurities, the ion exchange resin alone will not be able to handle it, and the life of the resin will be shortened. In the case of industrial water, the impurities are removed using sand filtration equipment or activated carbon, and the mineral content is pretreated using reverse osmosis equipment.

5. Dialysis Water

Tap water is used as raw water for dialysis, but tap water contains impurities that interfere with dialysis as various minerals. Reverse osmosis equipment is used to remove these minerals.

6. Boiler Water

A boiler is a heat exchanger that heats water by fuel combustion to produce hot water or steam. When water is turned into steam, the minerals dissolved in the water precipitate and adhere to the inner walls of pipes and other equipment, thereby interfering with thermal efficiency. For this reason, RO water from which impurities have been removed may be used for the water circulated as a heat transfer medium.