What Is a Bellows Pump?

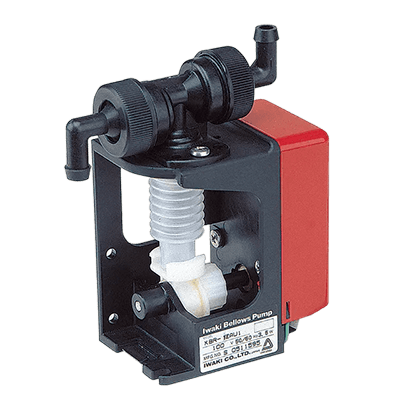

Bellows Pumps are pumps that utilize bellows, an elastic component with a bellows-like shape.

Fluid is discharged and transported by changes in the volume of the bellows. It does not require a shaft, etc., and features a low risk of fluid leakage.

Also, since the iron does not come in contact with the fluid, it can handle even hazardous chemicals, depending on the type. A wide range of types exist, from small, fine-tunable pumps to large pumps capable of handling flow rates of 30 L/min.

Uses of Bellows Pumps

Bellows Pumps are used to transport hazardous chemicals, chemicals that corrode metal when in contact with metal, highly viscous liquids, beverages, and other liquids. Specifically, they are used in a wide range of fields, including semiconductor manufacturing processes, chemical plants, food processing plants, and manufacturing plants for precision equipment such as printed circuit boards.

When selecting a Bellows Pump, it is necessary to consider whether the interior of the pump is suitable for the liquid to be transported, the pump’s transport volume, size, power consumption, sensitivity to stop signals, etc., and ease of maintenance.

Principle of Bellows Pumps

Bellows Pumps have bellows connected to a vessel with suction and discharge ports. A pressure vessel is placed inside the bellows, and the pressure is increased by a compressor. Valves are attached to the suction and discharge ports.

Some pumps have a single bellows connection, while other models have two bellows connections, allowing for the transport of large volumes of liquid. During the suction process, compressed air inside the pump is discharged to the outside, causing the bellows to contract. At this time, the suction valve opens and the fluid flows into the vessel.

During the discharge process, compressed air is supplied to the bellows from the pressure vessel, which closes the valve at the suction port and opens the valve at the discharge port, causing the bellows to expand. This pushes the fluid out of the outlet. These operations are repeated at high speed to provide a stable flow rate.

Types of Bellows Pumps

Bellows Pumps are classified into various types according to their operating method, bellows material, connection method, and application.

1. Classification by Operating Method

There are two types of bellows pumps: those that use bellows movement to suction and discharge liquid, and those that use pressure changes caused by bellows movement to move liquid.

The discharge method has a relatively simple structure, while the transfer method by pressure change enables more advanced control, but the device itself tends to be more complex.

2.Classification by Material

There are two types of bellows materials: metallic bellows and non-metallic bellows. Metallic bellows are resistant to high temperatures and high pressures and have excellent durability.

On the other hand, non-metallic bellows are used when resistance to certain chemicals and flexibility are required.

3. Classification by Connection Method

There are two types of bellows connection methods: single bellows and multiple bellows. The single bellows type uses a single bellows for suction and discharge of liquid.

On the other hand, in the multiple bellows type, multiple bellows work in tandem to convey a larger volume of liquid at high speed.

4. Classification by Application

There is a wide variety of models for different applications, ranging from general fluid transport to liquid transport under specific conditions (e.g., transport of hazardous chemicals, transport of liquids under high temperature and pressure, etc.).

Each of these types is designed for a specific application, and the appropriate Bellows Pump must be selected for that application.

How to Select a Bellows Pump

When selecting a Bellows Pump, the following points should be considered

1.Intended Use

It is important to understand “what is to be conveyed and how,” “what volume is to be conveyed,” and “is resistance to certain chemicals and temperatures required?

2. Longevity and Maintainability

Some Bellows Pumps have a long service life and do not need to be replaced frequently. However, some products require periodic replacement.

3. Cost

The cost of Bellows Pumps is another important factor. Not only the initial cost, but also the long-term operating costs (power consumption, maintenance costs, etc.) must be considered.