What Is a Pump Diaphragm?

A pump diaphragm is a pump that transports fluid by reciprocating a membrane called a diaphragm.

Pump diaphragms have a strong self-priming capability, which enables them to pump fluids that require high head and ultra-high viscosity.

In addition, pumps with a stainless steel interior are also available for sanitary use. Pump diaphragms are characterized by their ability to be cleaned and sterilized in place, making them useful in the food and pharmaceutical industries.

Applications of Pump Diaphragms

Pump diaphragms are used in lines where centrifugal pumps cannot be used.

- Where strong self-priming force is required

- Pipelines for ultra-high viscosity fluids

- Pipelines requiring high discharge pressure

- Food factories handling food products

- Chemical plants using ultra-high pressure equipment

In addition, pump diaphragms do not have rotating parts in the pump itself, which allow for relatively flexible material selection.

Principle of Pump Diaphragms

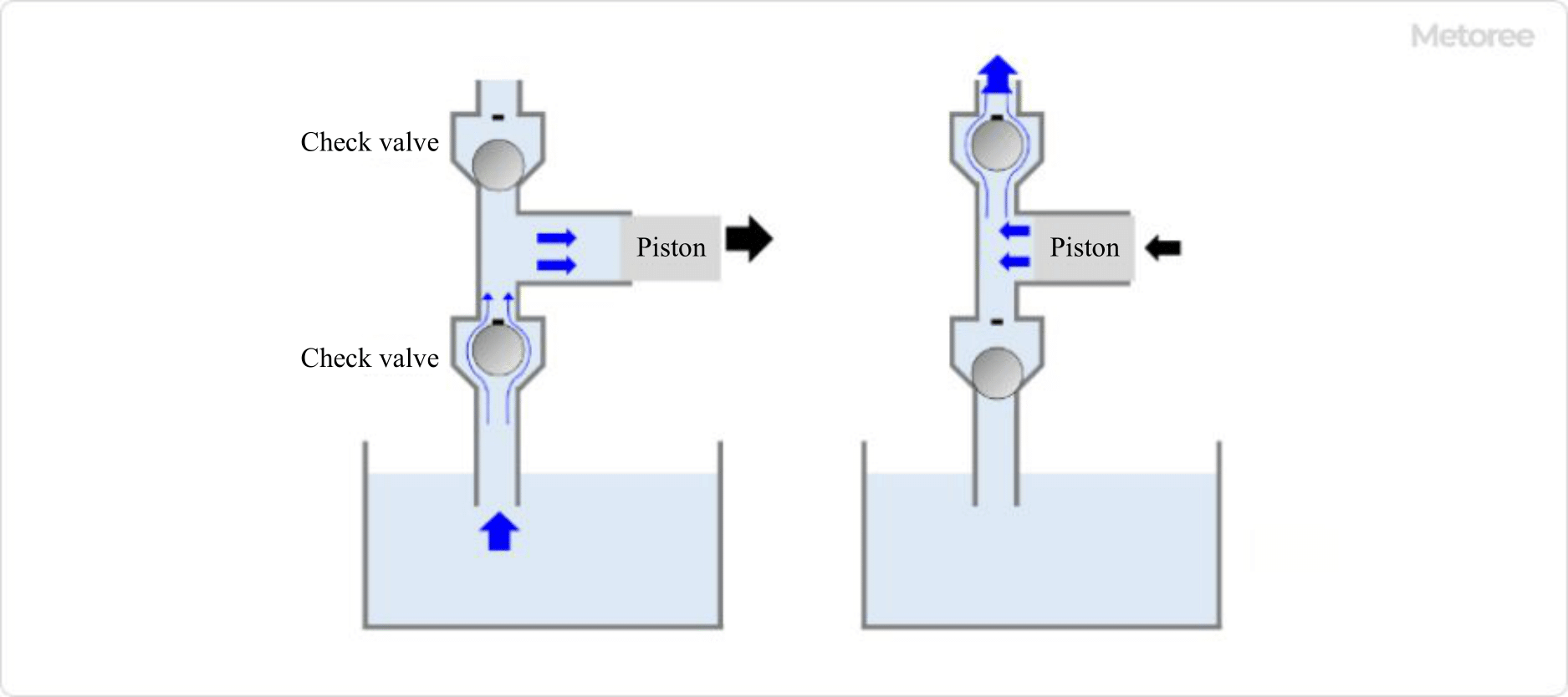

A pump diaphragm transfers liquid by repeatedly sucking and discharging it through the reciprocating motion of the pump diaphragm.

It is easy to understand if you imagine a syringe. When the syringe piston is pulled, liquid is sucked in, and when the piston is pushed, the liquid is discharged. A pump diaphragm uses a membrane called a diaphragm instead of a piston, and a check valve is provided on the suction and discharge sides to determine the direction of discharge.

Figure 1. Principle of diaphragm pump

Because of this structure, pump diaphragms always operate in either the suction or discharge direction, and the liquid flow is intermittent. This is called pulsation, and pump diaphragms cannot be used in lines where pulsation is not desired. If you want to use a pump diaphragm without pulsation, consider using a triple pump diaphragm.

Also, when driving diaphragms hydraulically, it is necessary to confirm that there are no problems with diaphragm breakage. In the food industry, there is a risk of machine oil getting mixed in with food, so countermeasures should be taken. Installing sensors, or other devices that will emit an alarm if the diaphragm is torn.

Other Information on Pump Diaphragms

1. Life Expectancy of Pump Diaphragms

The life of a pump diaphragm depends on the conditions of use.

Basically, if the diaphragm is not torn or the consumable parts are not worn or damaged, the pump can be used continuously. This should be considered as one factor.

If foreign matter or solids are mixed in the fluid, they can damage the diaphragm and lead to breakage, so care must be taken.

The general service life is about 3~4 years.

2. Pulsation of Pump Diaphragms

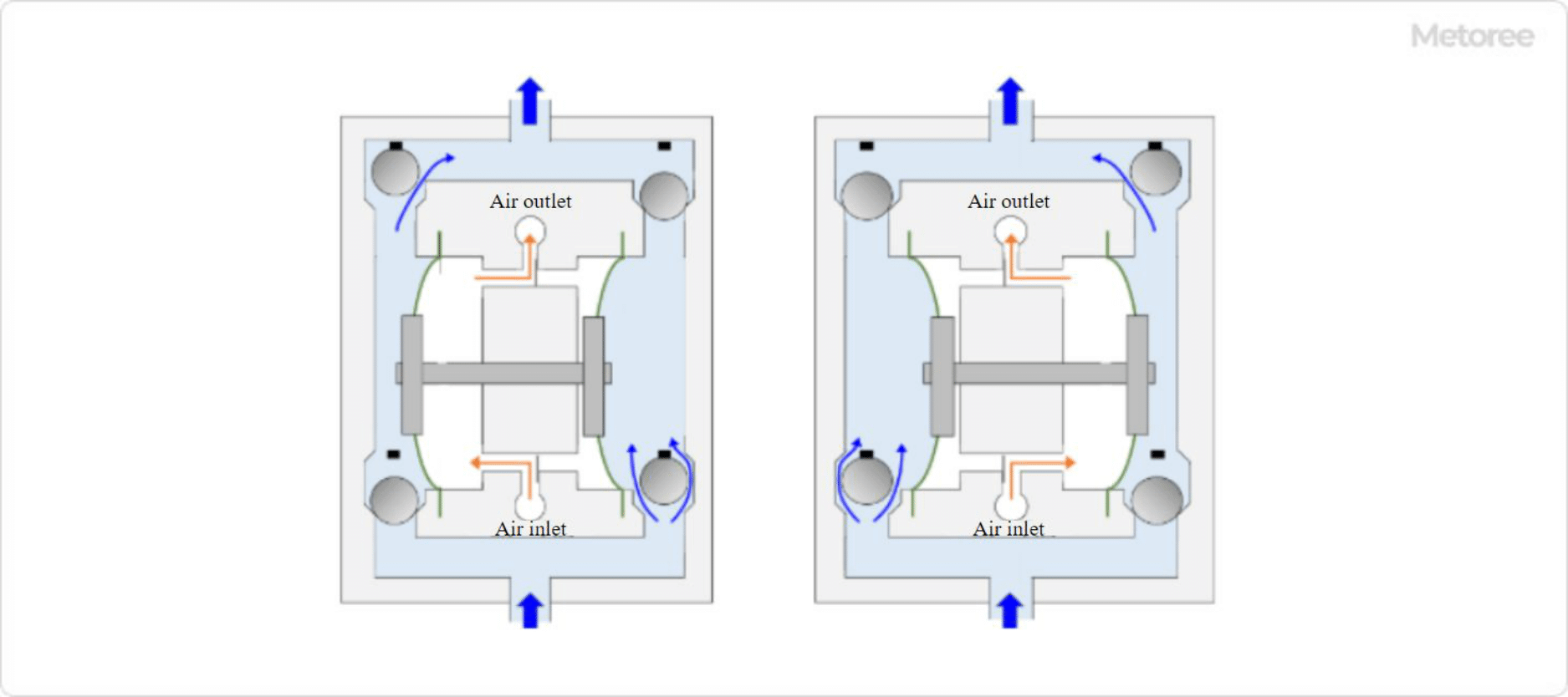

Pumps that use a reciprocating motion to transport fluid experience a phenomenon called “pulsation”.

Several methods exist to reduce this pulsation.

- Installation of an Air Chamber: A mechanism called an air chamber is installed at the outlet side of the pump. However, there is a risk that air may dissolve into the fluid if an air chamber is used.

- Use of Multiple Diaphragms: Use a pump with multiple diaphragms in a single pump diaphragm. While one diaphragm is suctioning, the other pump diaphragms the fluid, alternating between them to reduce pulsation.

Figure 2. Structure of a multi-diaphragm pump