What Is a Slitter?

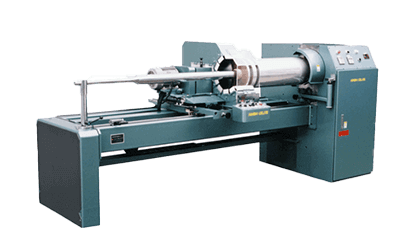

Slitting refers to cutting materials in the feed direction while conveying them, and a slitter refers to equipment that feeds materials and cuts them in any width in the feed direction.

Some slitters only have a mechanism to slit materials, but in many cases, slitters refer to equipment that includes a mechanism to feed materials, a mechanism to slit materials, and a mechanism to rewind materials slit to a certain width.

The material is slit with a blade, and the configuration, material, shape, and positional relationship of the blade are used according to the intended use.

Uses of Slitters

Slitters are used to slit thin materials such as film, paper, belt materials, rolled metals, and alloys into arbitrary fixed widths. These materials that are made into rolls are slit to cut into widths that are easy to use in subsequent secondary and tertiary processing because the width of the raw material is wide.

For example, in the case of aluminum foil used in the home, the base material is about 1200 mm wide. To use it as a product, it needs to be slit into 300mm or 100mm widths. Slitters are used for this process.

Principle of Slitters

A slitter cuts materials by combining an upper blade and a lower blade. The types of cutting used are:

- Shear Cut

The upper and lower circular blades are cut by shearing the material together. It is often used for thick film and paper.

- Leather Cut (or Feather Cut)

A leather or circular blade with a sharp tip is inserted into the groove of a roller with a narrow groove shape, or the material is cut in mid-air. The leather or round blade does not touch the lower blade or roller. It is often used for cutting soft materials.

- Score Cutting

The round-shaped upper blade is pressed against a roller (metal or rubber) and the pressure of the roller cuts the material.

- Gang Blade Cut

Both the upper and lower blades are cut using square blades. Generally, the upper and lower blades do not rub against each other but have a small clearance.

Although the main cutting methods are introduced here, each method is suitable for the material to be cut, the way the blade is applied, and other factors. The material to be cut needs to be considered in terms of thickness, hardness, and whether it is a single or multi-layered material. On the blade side, there are a number of factors to consider, such as whether the blade is driven, the blade edge angle, the force with which the blade is pressed, and the toe angle/camber angle of the blade. The cutting method is determined in consideration of the desired quality of the cut edge and the life of the blade,