What Is a Raised Access Floor?

A Raised Access Floor is a floor with a fixed height space under the floor. The purpose is to pass network wiring, etc., which tend to become cluttered, through the space under the floor. It is also known as free-access floor or a double-layered floor.

A Raised Access Floor is a floor with a fixed height space under the floor. The purpose is to pass network wiring, etc., which tend to become cluttered, through the space under the floor. It is also known as free-access floor or a double-layered floor.

Raised Access Floors do not affect the placement of desks and cabinets, making it easy to change wiring later. They also prevent damage to wiring and other hazards caused by human traffic and moving chairs.

Raised Access Floors have many advantages, such as improved aesthetics and easier cleaning.

Uses of Raised Access Floors

Raised Access Floors are installed in offices, factories, commercial facilities, schools, and other locations where many computers, servers, printers, network equipment, telephones, video equipment, and other electronic devices are used.

In the past, Raised Access Floors were used in computer rooms where large computers were installed in large organizations such as large corporations. Recently, however, due to the increase in the number of PCs and other OA equipment, and the spread of network environments such as LAN and Ethernet, OA floors are commonly used regardless of the size of the office.

When installing, it is important to estimate in advance the number of wires and load required. After installation, the wiring paths cannot be followed visually without opening the floor, so it is necessary to attach tags with numbers and destinations to the wiring ends and record them in drawings and management books.

Principle of Raised Access Floors

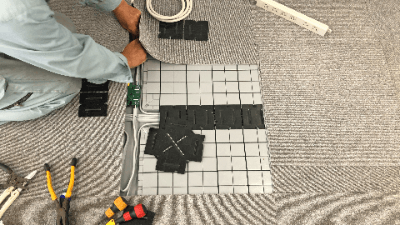

Raised Access Floors can be broadly classified into two types according to its structure: laid-in type and pillar separation type.

In addition, the wiring system can be roughly classified into two types: under-panel wiring system and groove wiring system.

1. Laid-In-Place Type

In the laid-in-place type, the pillar and panel are laid out as a single block. Most of them are made of resin, which makes on-site processing relatively easy, and the materials themselves are inexpensive, making them cost-effective. In this type, the floor height is fixed and cannot be changed later.

Because the degree of freedom in height adjustment is limited, this type is inherently unsuitable for installation in locations where the floor slab of a building has a difference in height and is not flat. However, there are products that can adjust the height using spacers. Due to the load-bearing capacity of the material used, these products are not suitable for installation of heavy objects.

2. Pillar Separation Type

In the pillar separation type, a pillar is erected on the floor and a board-like panel is placed on top of it. The height can be freely adjusted and the load capacity is excellent. The panel that makes up the floor and the support columns that determine the height are independent components, and the height of the columns can be adjusted, allowing the height of the floor to be adjusted as desired.

Therefore, the panel is suitable for use where there are steps or height differences in the floor of a building. And since metal products are the main material used for the panels, they are suitable for installation of heavy objects. In addition, there are products in which the panels are filled with mortar, which improves heat and sound insulation.

3.Under-Panel Wiring Method

The under-panel wiring method is a method of storing wiring in the cavity between the posts and legs, and has the advantages of large wiring storage capacity and a high degree of wiring flexibility. In the case of the separate-pillar type, the storage capacity can be further increased by increasing the height of the pillars. The disadvantage is that there is a possibility of interference.

4. Groove Wiring Method

In the groove wiring method, wiring is done along the groove of the panel, and a cover is placed over the top to protect the wiring. This method has the advantage of facilitating wiring changes and additions. Although the wiring storage capacity is small, wiring is done in an orderly fashion along the grooves, preventing interference. The groove wiring method is suitable when the number of wires is small or when there are plans to change the layout or increase the floor space.

Other Information on Raised Access Floor

Advantages and Disadvantages of Raised Access Floors

Advantages

- It has a cleaner appearance and improves work efficiency.

- Wiring outlets can be changed, allowing free layout changes of desks and PCs.

- Reduces problems such as falling over due to feet getting caught in wiring or data errors due to wiring disconnections, etc.

- Floor cleaning becomes easier.

Disadvantages

- Raised Access Floors have a limited load-bearing capacity and are restricted to heavy equipment. Also, since the height cannot be adjusted, they are not suitable for floors with slopes.

- Raised Access Floors with separate support columns have heavy metal parts, which may cause problems in workability and load-bearing capacity of the building.

- Depending on the equipment used, durability and walking feel may be defective. It is important to confirm this through testing.