What Is a Hydraulic Press?

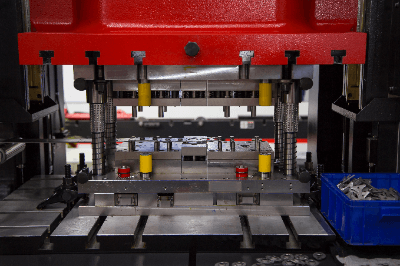

A hydraulic press is a device that uses hydraulic pressure as its power source to apply pressure to thin sheet metal and process it into the shape of a die.

The hydraulic motor sends oil to the hydraulic cylinder, and the piston in the hydraulic cylinder slides the die up and down to press it. Hydraulic presses are characterized by the speed of the slide, the pressure at the time of operation, and the long stroke. On the other hand, there is a risk of falling accidents due to oil leakage, etc., which must be considered when using hydraulic presses.

Applications of Hydraulic Presses

Presses are available in mechanical and servo motor types, depending on the operating system.

Although hydraulic presses have relatively slow production speeds, they can handle a wide range of materials and allow precise control of press speed, acceleration, force, and stroke length. In addition, large compression capacity can be obtained on a relatively small scale. These features make them suitable for small-scale production, drawing, and bending.

Hydraulic presses are mainly used in the processing of sheet metal materials for automobiles, home appliances, and electrical equipment. The types of presses available include cutting presses, deep drawing presses, injection presses, forming presses, punching presses, and forging presses. When selecting a press, it is necessary to consider the amount of press pressure, length of stroke, size of the press to be handled, and safety aspects. Examples of hydraulic presses in use are shown below.

- Pressing of a car body

- Pressing of gear outlines

- Pressing metal parts of lunchboxes and bathtubs

Principle of Hydraulic Presses

Hydraulic presses use Pascal’s principle to produce a large force with a small force. Pascal’s principle states that fluid in a closed container, regardless of the shape of the container, transmits the pressure per unit area received at one point directly to all other parts of the fluid. For example, in the figure below, F1/A1 = F2/A2 because the pressures on both sides are balanced, and F2 = F1 × A2/A1. In other words, the larger the area ratio, the more force can be generated.

Also, the principle of leverage allows the force (f) at the force point of the lever to be transmitted as a larger force (F1) at the point of action. By utilizing these two principles, a very large force can be generated even by human power.

It is important to note here that the larger the area ratio of the two sides, the greater the force that can be generated, but at the same time, the length that can be moved (stroke) becomes shorter. The stroke is determined by the amount of oil that is pushed out, and the larger the area ratio, the smaller the amount of oil that can be pushed out, resulting in a shorter stroke.

Hydraulic Press Structure and Principle of Operations

1. Principle of Operations

In the explanation of the principle, the manual method using a lever is briefly explained. However, hydraulic presses used industrially need to apply very large force precisely, so they use a hydraulic pump to push out oil. The following is an explanation of the operating principle of a hydraulic press.

A hydraulic press consists of a hydraulic pump, hydraulic cylinder, pressure control valve, flow control valve, directional valve, hydraulic tank, and a press section. The hydraulic pump, pressure control valve, and hydraulic cylinder are connected to the hydraulic tank. The pipe extending from the hydraulic pump is connected to the pressure control valve, flow control valve, and hydraulic cylinder.

2. Structure of Hydraulic Presses

When the hydraulic press is in operation, oil is transported from the hydraulic tank to the hydraulic cylinder by the hydraulic pump through pipes. At that time, the pressure and flow of the oil are adjusted by the pressure control valve and flow control valve to achieve the target pressure and stroke speed. The hydraulic cylinder is then pushed by the oil to operate the cylinder press. When the press is completed for the set time, the oil used is sent from the hydraulic cylinder to the hydraulic tank. It is possible to control compression by the cylinder, stop, and return the cylinder by means of a directional valve.